It has often been said that big bore Continental cylinders will not least longer than 800 hours.

Well, here’s a data point to the contrary.

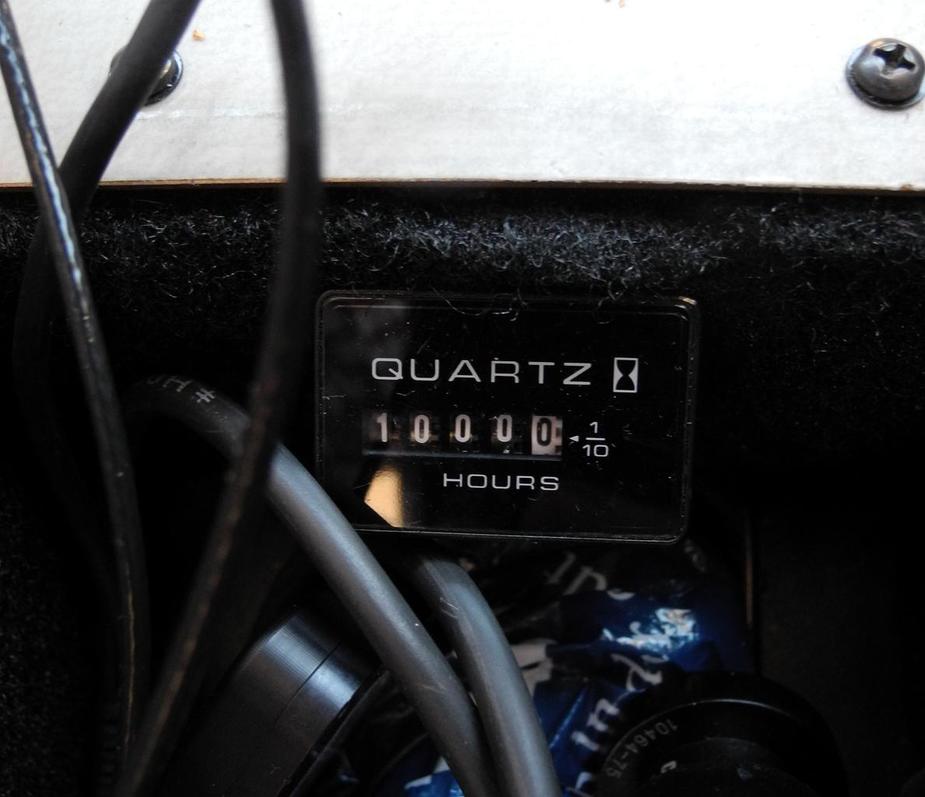

I just hit 1000 hours on the SR22 last week. It’s now 9 years old. Never has any of the cylinders been repaired, much less removed, overhauled or replaced. Compressions are in the mid and high sixties, which is perfectly OK for Continental cylinders.

I am not totally sure what has the most impact on the service life of a cylinder. But my guess is that CHTs do indeed play a vital role, especially in keeping the valves happy. I never go above 380F in the climb (usually more like 360) and normally cruise at around 310. That’s LOP, at about 60% power or 12.5 GPH.

On the other hand, I do a lot of things that could certainly be done “better” for the life of the cylinders: I use bog standard oil (W80) and change it only twice a year. I never preheat in the winter. Sometimes in the winter, the aircraft doesn’t fly for five or six weeks.

What I do though is be very careful with cold starts, making sure the RPM never goes above 1200 RPM in the first few seconds.

I have no idea how the camshaft, lifters, etc. look like.

While I can see anybody could shag a turbocharged engine so it needs a top rebuild at 800hrs, if a non-turbo IO-550 lasted just 800hrs that would be a scandal which would turn the SR22 into a joke, IMHO. I would have to ask why they fall apart so fast, when a Lyco IO-540 will easily make 2000hrs provided it is not abused or left inactive for too long.

Is there somebody saying seriously that non-turbo IO-550s make just 800hrs?

The other aspect of such a cylinder life is that there is a high chance of discovering cracks at each Annual (after the first few) and what is the difference between a crack visible visually (which is all one does to look for them – usually by looking around the lower spark plug hole which is near the exhaust valve) and a crack which has grown big enough for the cylinder head to come right off? If this really was happening, I wouldn’t do any long trips in such a plane.

I used to know a guy who used to fly a piston PA46 in the USA for overnight transplant organ transport and he said they were constantly replacing cylinders (in his view due to rapid climbs and rapid descents and a non-instrumented engine) but it didn’t matter because they were flying lots of hours and mostly between airports with facilities, so you would not get stuck somewhere in the back of beyond, as is so easily possible in Europe.

My SR22 has just over 1900 hours and I am just about to have the cylinders done for the first time.

If you operate the engine correctly, there’s no reason why it can’t go on even longer. There’s one SR22 in the US that has 3500 hours and is just about to be overhauled for the first time.

TSIO-520/550 eat cylinders, especially in installations where you need all the power (PA46, P210, etc.). 800h is considered to be a good cylinder lifespan.

IO-520/550 have no such issues. An SR22 should make 2000h at least. A SR22 allows you to cruise at 60-65% with very good speed. In a PA46 you need a lot more and a P210 is even slow and barely climbs when running at 80% BHP.

Spark plug hole cracks are a Lycoming cylinder speciality, head-barrel separation a Continental specialty.

Peter,

sure, going to 1000 hours without any cylinder work is not too extraordinary, yet several people for example in the Cirrus crowd (even non-turbo) don’t even make that. So I consider myself rather lucky.

While 3500 hours without a bottom end overhaul is entirely possible, it would be extremely improbable to go that far without any top end work. Even Mike Busch had to do that in his 310.

Yes, that’s right. The engine I had in mind had a top end overhaul at 2100 hrs.

So I consider myself rather lucky.

Or perhaps you are too modest/humble to consider yourself a pilot of at least reasonable ability?

The problem with populations (e.g. a population of pilots) is that you can find sub-groups in it who follow some sort of oddball preacher.

For example, on the Socata owners’ group there is a load of TB20 pilots who absolutely refuse to fly peak EGT or LOP. The guy who runs the group also takes a strict factory-POH line which is that since LOP is not mentioned it is not authorised and you should not do it. He takes a similar strict factory-aligned line on maintenance issues. And if anybody was to argue openly they will get kicked off the site and they all know that nowadays. I don’t know the politics of the Cirrus forum (I have been only to the non-paid section and got some pretty nasty treatment there which any moderator who is even half awake should not have allowed) but it is probably just like any other in that you get dominant characters there who have their followers.

I do not believe that 800hrs is a typical top overhaul period for a non-T SR22. If it was, there would be a lot of pissed off SR22 owners out there, because a top overhaul is a pretty major and expensive job with a lot of downtime. A cylinder is a 1000 quid, plus VAT and labour, plus the very substantial cost of the fuel burnt while flying at 75% + power while bedding in the new piston rings etc. But maybe it really is so… I wouldn’t know. The only SR22 private owners I have known personally have been fairly transient owners (who trade up regularly) who don’t care about costs and just drop the plane off at a particular UK dealer, no questions asked, or syndicates which only did short local flights at low level (a few k feet). And the one I knew a bit is at the bottom of the sea now.

The IO-540’s in the Aerostar ran to well over 2200hrs, so 400hrs over TBO. This for a turbocharged engine. I could not find any logbook entries about top overhaul, but that doesn’t mean it didn’t happen. I only chucked them in for overhaul as I myself got nervous – engines were still doing fine. The left one did burn a bit of oil, so that started to get me paranoid.

But even more bizarrely, my old Commander had a partial engine failure a few years ago on the left side. Chomped and crushed up two exhaust valves, oil and compression rings. The piston looked like it had been shot with a pellet gun for 40 years. Oil was all silvery and shimmering from all the metal. Camshaft was spalled. A/P’s didn’t want to fix it – they wanted me to overhaul. Me and my other mechanic convinced them to flush it profusely and put new oil in and just replace cylinders. They finally did, but they were not happy. Well, that engine went on to fly for the remainder of my tenure – and is still flying! Engines are at least 300hrs over TBO by now and less than a month ago the old girl make the pilgrimage from Los Angeles to Vladivostok! A 8000nm trip up over Alaska and Siberia. When I got the crazy Russians on the phone after they’d arrived I asked if there had been any malfunctions. “None”, they said. This from an aircraft that had been sitting idle, out of annual, for almost a year before they picked it up.

Sometimes you just don’t know.

Great story Adam. We all loved your Commander travelogues on youtube and are eagerly waiting for some more with the Aerostar, now that it’s back in the air.