So I decided to bite the bullet and purchase the ALT-FLX-1 alternator instead

As is usual nowadays for any aviation hardware not in stock, I got a quoted LT of 30-45 days and a 600USD price delta vs the ASG12000. I was starting to wonder (and still am) whether I am throwing good money onto bad with HET.

Exactly 60 days after I placed my order a brand new ALT-FLX-1 showed up together with install kit and STC approval to use but no STC paperwork, just an 8130-3 for the NEW alternator P/N 17-2000-1 and another one for the P/N ALT-FLX-1 ALT-FLX FORD DOFF KIT installation kit, consisting of a new FLD connector and a couple of crimped-in 16ga wires (overkill for 4 amps, but they possibly use the same wires in the 12V installation rated for 10 amps) . All of the STC documentation is however available on line.

The side-by-side comparison with the Fordausaurus is quite impressive as it looks smaller, lighter and a lot more modern-car like .

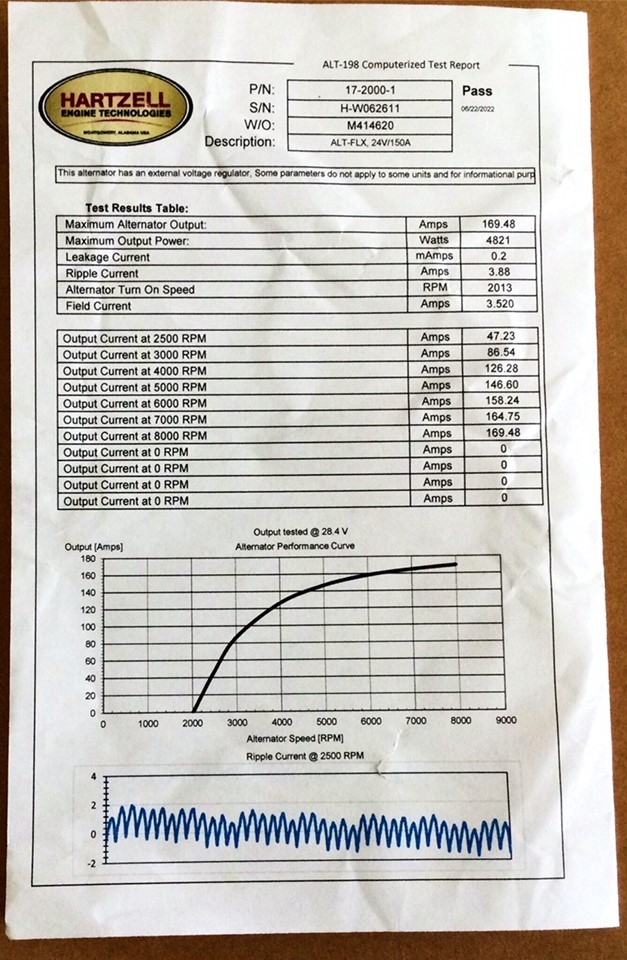

Just like the prior ASG12000 a SN-customized bench test report was included. Interestingly the reference voltage used on the FLX was 28.4V (vs 25.6V on the ASG) making a direct comparison difficult: you need to assume proportionality for Volts vs RPM and that only works outside the high-current magnetic saturation regime.

Idle performance (my main concern, other than normal reliability, see above ) should be similar. Full rated performance on the bench is impressive all the way to 170 amps but I have no intent of testing it on our aircraft: the 150AMP rating will be useless in my installation since it is rated for the OEM 95-amp Fordausurus with a 100-amp breaker. Replacing the breaker with a 150-amp should be treated as a major mod and is not included as part of the ALT-FLX STC, so it is effectively de-rated to 100amps in our installation.

Pulley size is the same as the ASG and E3FF alternators so RPM ratio is still 2.75:1 so in reality it will see 6875 ALT rpm in cruise at 2500 engine RPM, which on the bench results in a less impressive163 Amps .

Not that it makes a difference since I have no way of drawing more than 75 amps on our P210 aircraft unless I am using the engine starter. I guess we should see a more stable bus voltage when operating the landing gear hydraulic pump while using all heaters, deicers, lights and avionics.

Antonio wrote:

Hopefully our [ASG12000] Planepower lasts a bit longer than yours.

Oh, well, it did not. Performance was every bit as advertised (read above) … while it lasted.

We had two events of intermittent performance where charging was lost for five minutes without anything we could do about it. Both ALT and FLD breakers had remained activated and resetting them would not fix things. On our aircraft, there is a POH procedure to reset field breaker to reactivate a tripped overvoltage relay, in case it was the problem, but it was not to be. Normal ops resumed in both instances without further ado when restoring field power by turning ALT switch back on after a few mins. The system was troubleshot on the ground for intermittent connections but every time nothing was found faulty.

In one of the instances the situation got a bit more anxious than I like it but in both cases our back-up B&C alternator took the cruise electrical load easily.

Eventually the ASG12000 gave up the ghost entirely after a total of 77 flight hours.

HET/Planepower honoured the warranty with a full credit via their dealer after two months and four days of bureacratic tofroing troubleshooting, once the fault was verified. We had had to supply the details of on-aircraft troubleshooting before an RMA number was issued. This is to be expected to avoid processing a warranty claim for what ends up being a faulty on-aircraft connector or some other ship-side (vs alternator) fault.

We had previously purchased a replacement HET alternator of a different model, but otherwise I think standard warranty terms mean be the supply of a replacement new or repaired unit rather than a credit.

This of course left me cash-out for the best part of two months. At least I had a replacement alternator immediately (read on) available.

You don’t even need to remove the belt from the pulley, just slacken the tensioner bracket and hold the belt so that it doesn’t rub against the pulley.

Jujupilote wrote:

Does it require to remove the prop at each annual ? is it usual ?

You only need to remove the belt from the alternator-side pulley, not the prop-side, so you do not need to remove the prop.

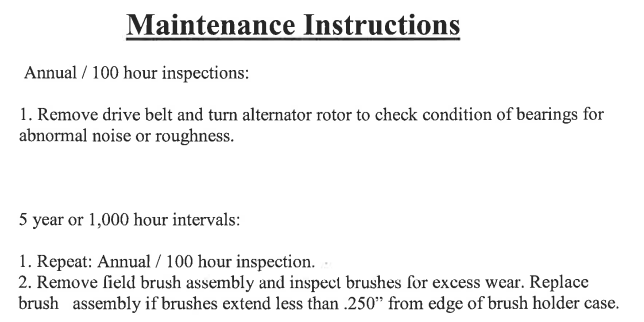

Planepower states in its installation instruction sheet :

Does it require to remove the prop at each annual ? is it usual ?

I thought one would just check the belt tension and general state of the alternator, if power is produced normaly.

What is the difference between “Instructions for continued airworthiness” and “Maintenance instructions” ?

The former seems more official

I measured the field current on the main TB20 alternator and it is about 2.5A.

Sorry to hear that but glad you resolved it.

Hopefully our Planepower lasts a bit longer than yours. At least for now it is delivering much more power than the Fordausaurus. Since the warranty term is three years /1000hrs one would hope they are putting more effort in making sure it endures.

We do have a B&C backup alternator, but there is no main B&C alternator available for our aircraft.

my RV-8 had about 100 hrs when the brand new planepower alternator gave up its ghost. The failure was insidious and hard to detect until my Garmin panel started to fail. I removed it and took it to my friendly automotive alternator repair shop where we opened the unit. According to my friend the winding was poorly made and h used an alternative to real cooper. I was amazed at the inner construction and watched him re do the winding with the real material. The repair cost less than 100 dollars and since it is experimental I replaced it back. It has functioned flawlessly for more than 100 hours since. When I was pricing a new planepower unit the cost came close to 1000 US. I suggest considering a B+C alternative unless fabrication from planepower has improved.

I did not measure field current with the old one but I measured the new ASG at a bit less than 2Amps with engine stopped, which seems to be saturation current as it matches the manufacturing test data.

Max current for our Zeftronics regulator is about 4 amps.

Field resistance of the old Fordausaurus was 11Ohms, the new ASG 16Ohms.It seems to have more field windings turns for a more powerful rotor magnetic field with the same field current.