To update this old thread, some pics from a few years ago which someone may find useful:

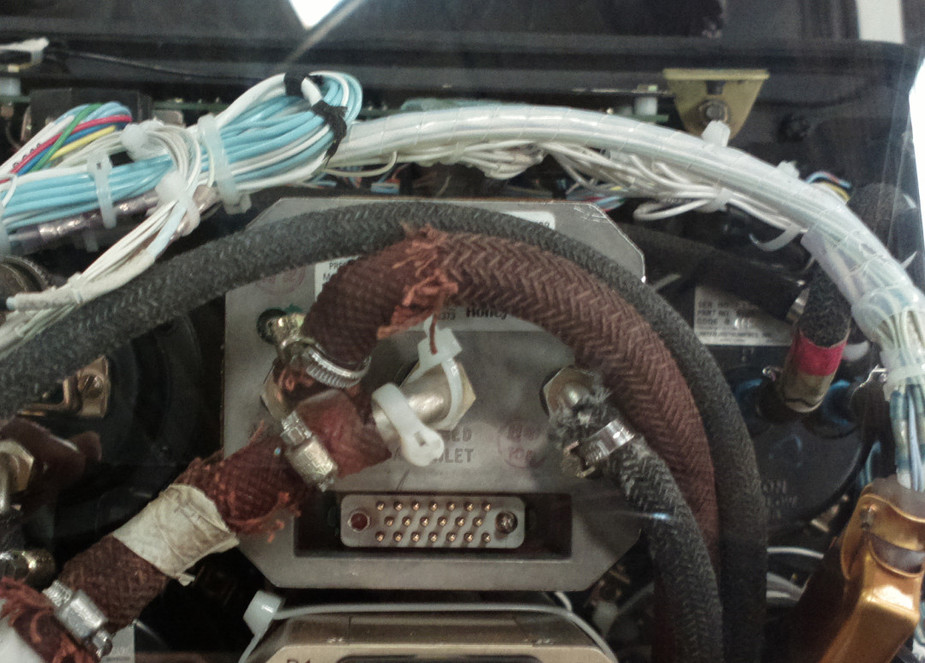

Before:

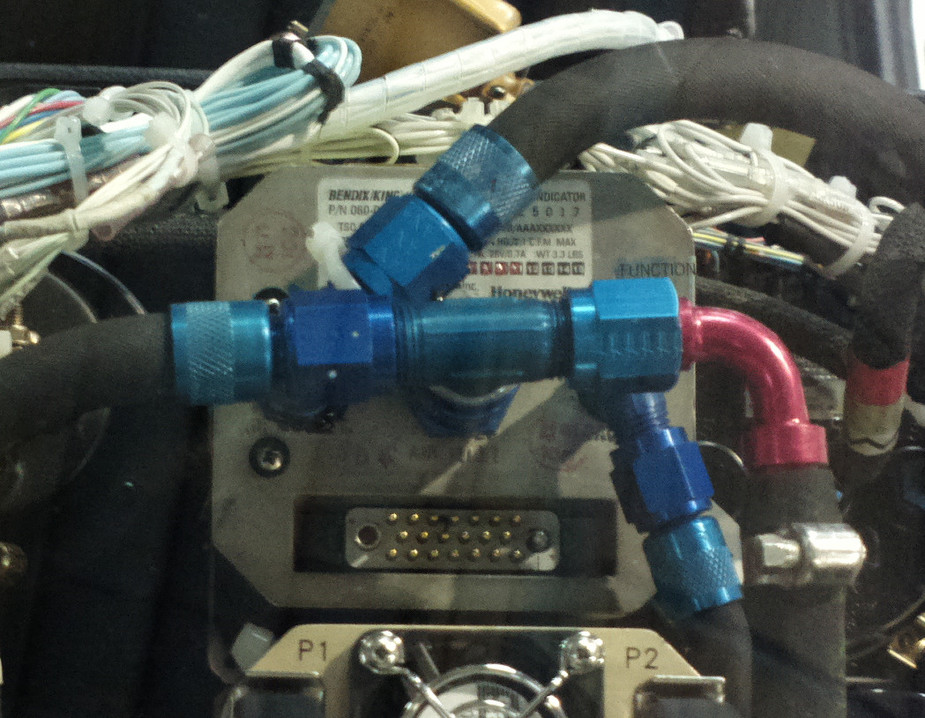

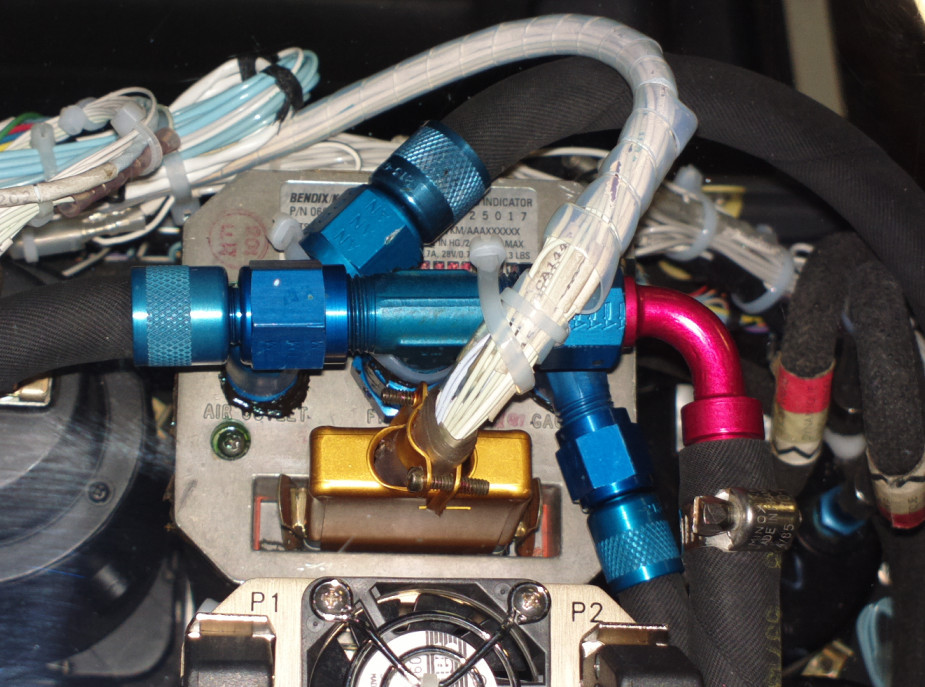

After:

(sharp observers will spot that the instrument centre hole fitting is not an off the shelf item)

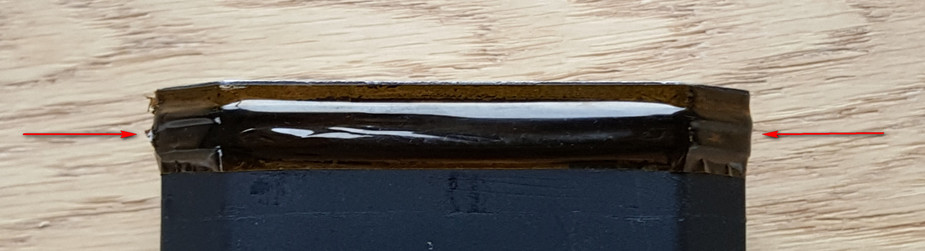

Some pics are bad quality because they were taken through the front window, but they show the basic idea. This job is really worth doing because it transforms the KI256 replacement task from a 1-2 hour finger-skinning and knuckle-bleeding job to a 5 minute task, with the biggest remaining problem being the extraction of the KI256 itself whose body is “thickened” by the use of sealing tape and it is difficult to get it through the tight fitting panel hole

I am pleased to report that the pipework was re-done very successfully, with the AN fittings from Aeroquip.

There is a very significant improvement in the vacuum too. For the main feed – a long hose from the vacuum regulator to the KI256 – we used a 306 hose of the correct ID (306-6 – called “3/8”) and the improvement in the vacuum shown on the gauge is roughly equivalent to what I have previously seen between a brand new vac pump and a shagged vac pump. Evidently the old hose, being of a very slightly smaller diameter, was restricting the airflow measurably.

The space behind the LH instrument panel is quite tight, however.

I have not had any instrument failures. I was just trying to tidy up the pipework, to ease the removal/replacement of the KI256 which needs a periodic overhaul to replace the bearings.

Some of the TB hoses do have a 10 year life but AFAIK not these. The heater hoses might be (under EASA) and the flexible engine (fuel and oil) hoses are not lifed if they are Teflon.

I am very suprised the colourful silicone hoses would be regarded as usual. Not saying there is anything wrong with them – just saying they would look rather “unusual”  In this game, one needs to think not just of what can be signed off immediately but what somebody unconnected might question afterwards. For example when I had my engine rebuilt in the USA (SB569) I had a choice of different colour paint, with some very “hey I am here” bright red options. I went for the Lyco grey, somebody seeing it might think that I got the engine gas flowed by some hotrod shop, and you know how the GA scene is full of gossip. Maybe I am overly careful?

In this game, one needs to think not just of what can be signed off immediately but what somebody unconnected might question afterwards. For example when I had my engine rebuilt in the USA (SB569) I had a choice of different colour paint, with some very “hey I am here” bright red options. I went for the Lyco grey, somebody seeing it might think that I got the engine gas flowed by some hotrod shop, and you know how the GA scene is full of gossip. Maybe I am overly careful?

Peter

Although the pictures of the back of you instrument panel look tatty I think you should ask yourself whether you have had a failure because of it. Some other aircraft manufacturers specify a 10 year life on those hoses. I have replaced some of these hoses with silicon using red for pitot and blue for static

similar to: http://www.silex.co.uk/products/silicone-tubing/

Many thanks Vic – “swivel” is the word

The orifice in these is going to be a lot smaller than in the straight-through ones, and I do know the vac pump really needs all the air it can get, so I will look into these if I am unsuccessful with the AN ones.

if you looked closely at these pneumatic industrial fittings – nothing “consumer grade” about them – you might have found that they are the swivel type, meaning you hold the elbow in one orientation and screw in the threaded part. And this seems to be your real problem on those instruments. Of course you can find NPT types in the US if you really care about the one pitch mistake per inch. I still suspect the diameters of British pipe and NPT close enough for your application. The proper seal is effected by O-ring or thread sealing, and when using Loctite on the thread the pitch difference is irrelevant for the strenght of the connection.

I don´t know how much airflow is really going through these hoses, I don´t think a lot. This should be noticable at the exhaust of the vaccuum pump to get an idea. But then for limited space you could take smaller hose like 8 or 10mm i.d. and go for larger for the rest of the lenght if you like. If you do want to keep rubber hose for flexibility you may go for banjo fittings but you may have trouble to find NPT hollow bolts. NPT seems to be somewhat obsolete now…..

A good strategy would be to introduce your “revolutionary” design first to the inspector before fitting it. So he would not feel offended by facts not authorised by him earlier. I am quite sure my EASA CAMO shop would not object to this much better arrangement in aspects of durability and ease of service. But then this is a matter of personal relations between examiner and owner plus faith in owner competence.

http://www.ebay.com/itm/Qty-2-Pneumatic-Push-fitting-Male-Elbow-Swivel-1-4-OD-Tubing-x-1-4-NPT-/300919412751

http://www.ebay.com/itm/Qty-10-One-Touch-Push-fitting-Male-Elbow-90-3-8-OD-Tubing-x-1-4-NPT-/301058245218

http://www.ebay.co.uk/itm/Metric-BANJO-x-Hose-Tail-Fitting-Diesel-Petrol-Oil-Tube-Pipe-Fuel-Filter-Head-/280778348867

http://www.ebay.co.uk/itm/Banjo-Fitting-for-6mm-8mm-10mm-hose-Banjo-Bolt-Fittings-Fuel-Hose-M10-M12-M14-/280739026733

Yes those pneumatic fittings do look nice. They are widely used in industry.

Not sure I would use your suggested tread adaption method however  But NPT is common in the USA and there would be US versions of these.

But NPT is common in the USA and there would be US versions of these.

One issue I see is the much reduced cross sectional area of some of them. One doesn’t get something for nothing; to maintain the ID at say 9mm you end up with a fairly large fitting no matter how you hack it. One can see why people use those crappy fittings with jubilee clips – they maintain the ID and are not too bulky. Of course they are dirt cheap too – with the $10000 KI256 you cannot afford to spend too much on fittings

However it is also a fact that a reduction in the ID which is present for only a short distance is not much of a problem (do a google on airflow head loss, etc). There are even online calculators e.g. here but how does one get the velocity figure? I bet that nobody has ever worked it out properly and people just use the same fittings because they always have done. I do know that when using the electric vac pump (to erect the KI256 for ground work) one does need a big hose – at least 12mm ID – but that hose is perhaps 2-3m long.

The issue with the back of the KI256 is not the size of the fittings but the clearance required around it in order to be able to screw it in without hitting the one(s) next to it while it is being screwed in.

Obviously anything is possible if you have enough room behind the instrument. In the TB20 there is about 70mm before it hits the airframe while the LH panel is being tilted.

I think I have a good neat solution which I will post here when I have the required bits.

the A&P or A&P/IA needs to ascertain that the component is “airworthy”….having traceability via an 8130-3 or a Certificate of Conformance to an FAA approved design certainly makes it easier to determine airworthiness but is not the only way….

Indeed, though I would rephrase it as "how provocative would “solution x” be to an FAA inspector". AN fittings, no, because he has seen them before, and it is “self evident” that it is a perfectly airworthy solution (even if it is completely nonfunctional). Anything “consumer grade” one needs to be careful and I would not do it, notwithstanding the improbability of it being inspected in the European scenario.

So traceability should not be an argument for the annual to a decent mechanic.

In fact the FARs do not mention traceability at all….the A&P or A&P/IA needs to ascertain that the component is “airworthy”….having traceability via an 8130-3 or a Certificate of Conformance to an FAA approved design certainly makes it easier to determine airworthiness but is not the only way….

your troubles did not come unexpectedly to me as I think this AN system is far too bulky for this place. So I really suggest you looking at these pneumatic fittings below. What size of NPT thread is actually required and did you try normal pipe thread ? Provided you apply some mild Loctite or teflon tape the slight difference in pitch really does not matter. I suspect both threads being very close in diameter and so should be fine for next to no pressure. Just don´t tell me these fittings not being certified for aviation whereas rubber hoses and clips said to be so !!! This could only be a joke and a disgrace anyway – not to be published to uninformed people outside aviation.

Vichttp://www.ebay.co.uk/itm/Pneumatic-Push-Fittings-Air-Water-Hose-Tube-ALL-SIZES-AVAILABLE-Stem-/261120824703

http://www.ebay.co.uk/itm/1-4-NPT-Male-1-4-Bsp-Male-Adaptor-Nipple-Air-Water-etc-b277-/110973971376

http://www.ebay.co.uk/itm/6mm-x-1-4-Bsp-Push-Swivel-Elbow-Fitting-s-s-claw-b82-/120920062062

http://www.ebay.de/itm/Winkel-Schwenkverschraubung-Steckverbinder-Messing-alle-Grosen-/220984725349