FWIW I think the best aircraft batteries are Odysseys, if you can get them approved for the airframe. They are almost universally used on FAA Experimental Category aircraft in my area, and some certified aircraft too. They make some certified units: http://www.batterymart.com/p-hawker-sbs-J16-aircraft-battery.html

I have noticed that AGM batteries tend to fail almost instantaneously.

Concorde are better than Gill, although I was amazed to see that the Concorde terminal bolts installed into a soft, copper female thread. Very vulnerable to damage and over-torque. I use one on my plane and keep it on a Battery Tender any time it isn’t being flown. With twelve vehicle batteries simultaneously in service (and one driver/pilot) I learned the hard way how to extend their calendar life by keeping them all charged up, all the time.

Hi Jan,

yes, Bosco already explained it all … in the SR22 it is essential that the batteries are both in good condition, especially BAT1. In case you lose ALT1 you can still use the autopilot until the battery is empty, the DFC90 autopilot (contrary to the S-TEC55) will not work anymore once BAT1 is empty. So the strategy would be to hand fly in this case and conserve as much battery power as possible in case you need the A/P for the approach.

A good battery capacity check takes hours. I guess that is one of the reasons that it isn’t performed often. A lot of maintenance manuals say you have to “check” the battery. Only a few say that you will have to conduct a capacity check .For example on Diesel power aircraft, who are more depending on electrical power that Lycoming or Continental powered aircraft.

For IFR flying it would be very usefull as well.

Most quick battery analyser can give an indication, use a high load test, however with a good test, the battery will first be fully charged, and then uses a low discharge over a longer period. This is how you would use your battery during flight if the alternator fails. Afterwards the battery has to be recharged if found serviceable.

Especially with lots of avionics I would recommend to follow the manufacturers instructions, or check brushes after 500 hours which ever comes first. Some manufactures say that their alternators don’t need to be serviced ever. When brushes worn out the brush springs can ruin the alternator rotor, which is expensive to replace.

On some aircraft, suchs a older Piper and Cessna aircraft there isn’t a good voltage warning light. For example at the Cessna the voltage warning light goes on when the alternator regulator doesn’t receive input voltage form the aircraft. This is because an overvoltage condition will trip the overvoltage protection, stopping the supply of the regulator, illumination the warning light. If the alternator itself fails you won’t get this warning light, as the voltage regulator still receives voltage. A faulty alternator can then be undiscovered untill equipments starts to behave strange or switches off.

Some countries such as the UK have additional requirements for these warning lights for IFR flights. It could be usefull for those flying IFR in other countries to also use a proper warning light, or at least be aware how the systems works and behaves during an alternator failure.

A good battery capacity check takes hours

That’s a good point. I am going to find out what is the normal practice. The shop where I am hangared does it at 1C rate so the battery should last 1 hour, and I guess there is a spec on the minimum voltage it should be holding at the 1hr point. But I recall seeing much faster load tests done elsewhere and those would involve much more current.

The faster you discharge a battery the less capacity it has.

For example at the Cessna the voltage warning light goes on when the alternator regulator doesn’t receive input voltage form the aircraft

That’s really bad. They should be using an undervoltage detector like this

That is, at least for flooded and sealed Gill batteries the correct methode, in accordance with the Gill’s instructions:

Flooded:

http://www.gillbatteries.com/pdfs/Flooded_Service_Manual.pdf

Sealed:

http://www.gillbatteries.com/pdfs/VRLA_Service_Manual.pdf

And also for the Concorde batteries:

http://www.concordebattery.com/otherpdf/5-0171.pdf

A 30 second tester for example, does simply not meet the requirements of the instructions as laid down by manufacturer, (for Gill / Concorde at least)

The poor design of older Cessna’s and Pipers voltage warning lights is the cause that UK caa has CAP746 generic requirement 6 I suppose .

Across the three American aircraft that I own the Concorde gel battery’s have been a great success with a life of 150% of the Gill battery.

One battery was not however immune from the very well qualified ( on paper ) Licensed engineer who when my back was turned levered the top off the Concorde gel battery to inspect the electrolyte level……………… He won’t be back !

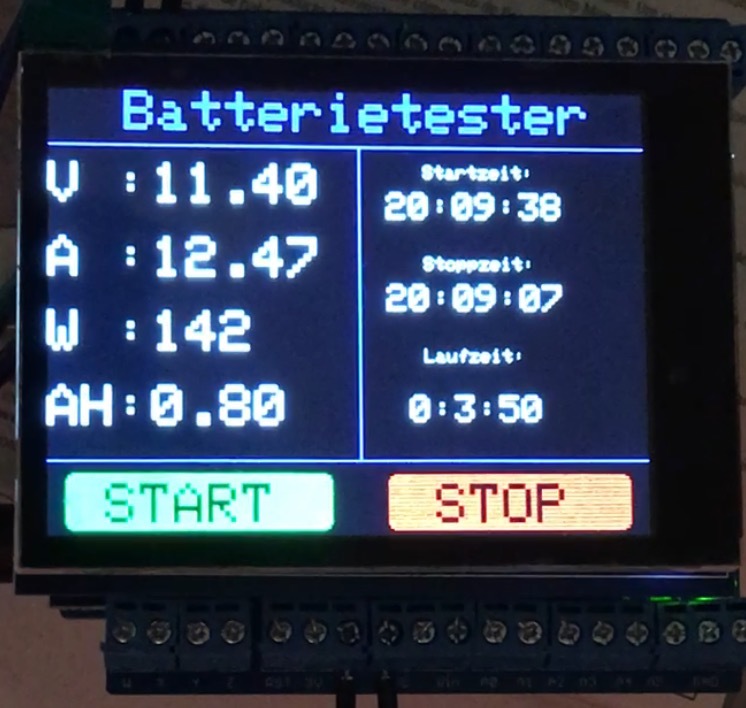

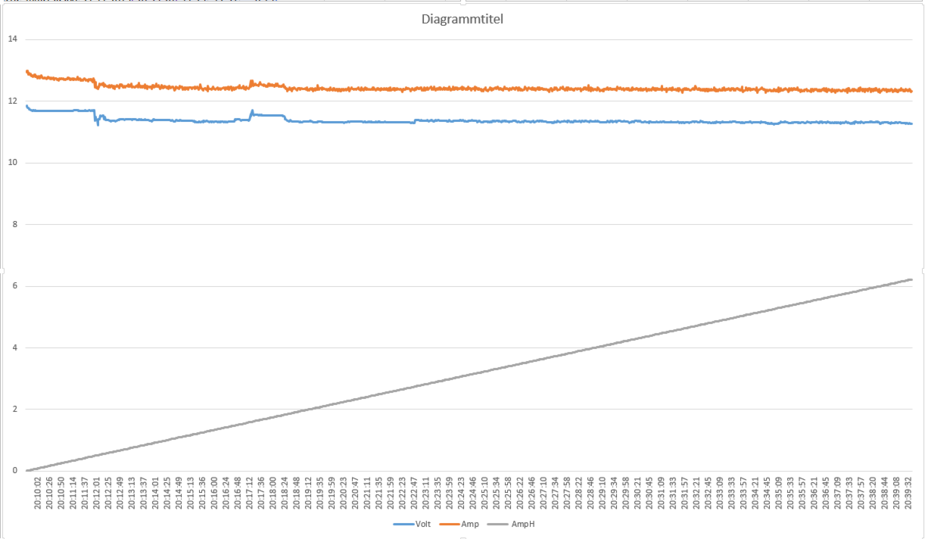

I used the bad weather to build a small load tester that does the load test according to the manual (1C discharge, automatic disconnect at the predefined voltage). HW base is a small and cheap Arduino with a touchscreen. Load is simulated with halogen bulbs. It stores all the data on a MicroSD card for later visualization in Excel.

Nice job!

Hi All interested in battery charging and capacity testing. After reading MM for Gill and Concorde batteries, I created the following setup with iCharger 4010DUO, which comes from model hobby world, which is more high-tech regarding battery charging and discharging than general aviation. What is more, iCharger 4010DUO can work with external dummy load allowing around 1kw discharge, which is more than sufficient for GA aircraft batteries up to Piper Meridian. As they say, one picture often says more than thousand words so I am attaching few pictures on the setup. This particular setup allows for exact charging and discharging and capacity testing as prescribed by Gill and Concord MM. Feel free to ask any questions. I am using this setup for 1,5 years. Also, this can be used for any charging of practically any chemistry batteries you may find and use at home so it is highly versatile and useful :-). Highly recommend. Price of iCharger on Amazon is 317USD, can be found on Europe RC eshops as well. The rest is cheap but involves some manual work.

@Pytlak: my compliment (and my heartfelt envy!) at your creative work. I would never be able to produce such a neat clean job of mechanical construction, well done indeed! But then, I can’t help suspecting you of having an extensive stock of alu extrudings at hand AND some CNC tool ( s ) …