Note the black hose at the upper blue arrow that goes into the intake of cylinder #6. It's a turbocharged Lycoming O-540 in a Cessna TR182.

The lower blue arrow points to a turbine outlet temperature (TOT) sensor which is also strange because that number is kind of pointless to know.

Stand-by vacuum source?

Exactly. I did not know that this exists and I wonder how well it works.

The engine has ca 9l of displacement, every 2 rotations a cylinder is filled, at 2400rpm this would be 2400/2 * 9l / 6 = 1800l/min of fuel/air mixture flowing through that one intake. Due to Bernoulli's law, the fast flowing gas creates a low pressure which in turn drives the vacuum.

I am surprised that it is strong enough to drive a gyro and I wonder why this additional air sucked into the intake would not mess up the mixture in cylinder #6. It would run leaner and apparently not by much, otherwise this system wouldn't work.

I can't see this working at any significant altitude (say above FL100) because you need a wide open throttle just to get decent power.

And I completely agree about messing up the mixture in that cylinder. I guess this was put in before engine instrumentation became popular...

I didn't think this arrangement would work on a turbocharged engine....obviously manifold pressure needs to be lower than ambient ( by 3-5") in order to drive the gyro...strange

I presume it is only effective at low altitude and with the throttle pulled to achieve enough delta P

A Dyson or Hoover type vacuum cleaners will drive your instruments; I've used these for testing. There is also a vacuum relieve valve built into the aircraft system and this set to give 5 in/hg (usually?) This is meant to be an emergency system so the impact on engine performance is not the priority.

Here's such a system by The Vacuum Source.

Indeed, it says it works by the difference in manifold pressure and ambient pressure. This renders it kind of useless in a TR182 which is usually operated at or above ambient pressure through its turbocharger (max MP 31", maintainable until FL200).

That would require a constriction in the manifold tube....which I doubt...what does it say in your POH in terms of operating limits for the system?

Bear in mind that your MP gauge is measuring the pressure in that same fast-flowing stream....the only way to lower the pressure is to increase the velocity by a restriction...like the Bernoulli tube some old-time aircraft have in the slipstream

[edit: sorry just noticed you agreed...]

It's not my aircraft, my engine compartment doesn't look nearly as nice as this one

Today, vacuum is either not required at all or serves as a backup for glass cockpits so the demand for such a system should be exactly zero.

A Dyson or Hoover type vacuum cleaners will drive your instruments

I am sure they work, especially the Dysons whose 140db noise level is very reassuring

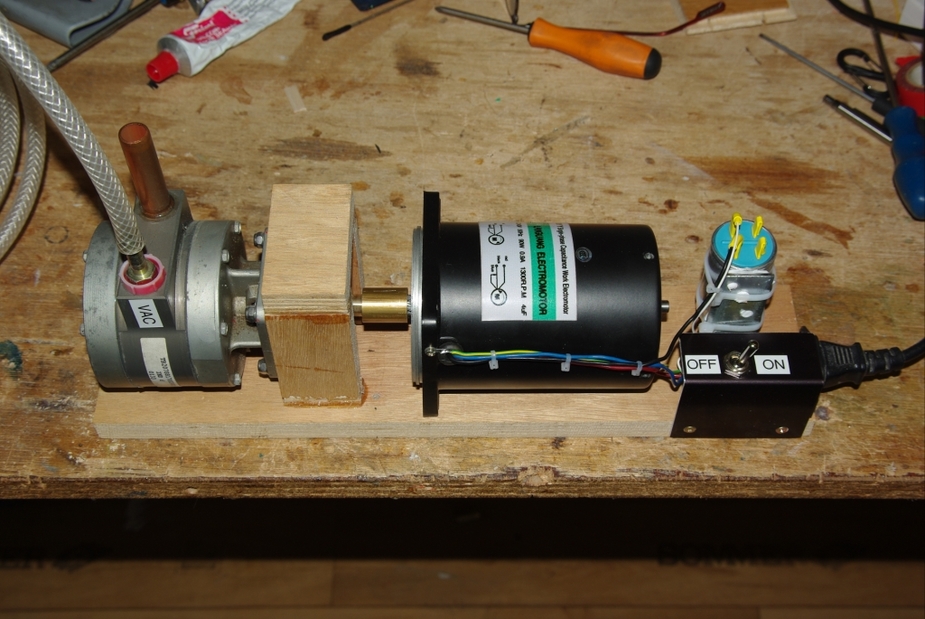

Years ago I built this

and it is quite staggering how much power it takes to turn the vac pump at say 1500rpm. That mains powered motor is about as small as one can get away with.

This is meant to be an emergency system so the impact on engine performance is not the priority.

I think that may be misguided - depending on which way the mixture gets altered. If you introduce extra air into one cylinder, you will make it richer, which could push it from LOP to some ROP region, which might up the CHT quite a bit.

I suppose it is still worth having however especially as it is really simple and much lighter than the electrically driven vacuum backup systems.

Today, vacuum is either not required at all or serves as a backup for glass cockpits so the demand for such a system should be exactly zero.

I don't think one can legally avoid vacuum on single-alternator aircraft - unfortunately. Doubly unfortunately if your King autopilot needs the KI256 for which there is a great electric plug-in equivalent but which is not on the AP STC...