I just thought to get to know maybe newer or other measurements to prevent this stuff asap as long the expense is small but looking onto those prices for this kind of patented Alodine containing pen, hm.

I am sure they are original. That is how Socata did it.

I think those rivets are stainless steel, which is a curious choice on aluminium, no?

@Ultranomad, yes o.k. that sounds to be a good deal but didn´t find a (continental) european shop selling small amounts for a resaonable price though. Still looking around to find a good price to order. Some shops you even have to ask for a quote….strange times right now.

@Chris, Alodine (now called Bonderite M-CR) pens work as promised, but are outrageously expensive indeed. A 2-litre kit of two-component brush-on Bonderite M-CR ALCRM 1200BR (formerly Alocrom Brush) in bottles costs less than one pen containing something like 50-75 mL.

Txs, found that kind of touch up pen containing Alodine – seems to be a solution for these kind of small areas although maybe not working absolutely accurate but helping to stop corrosion a bit. Quite expensive stuff from a known brand.

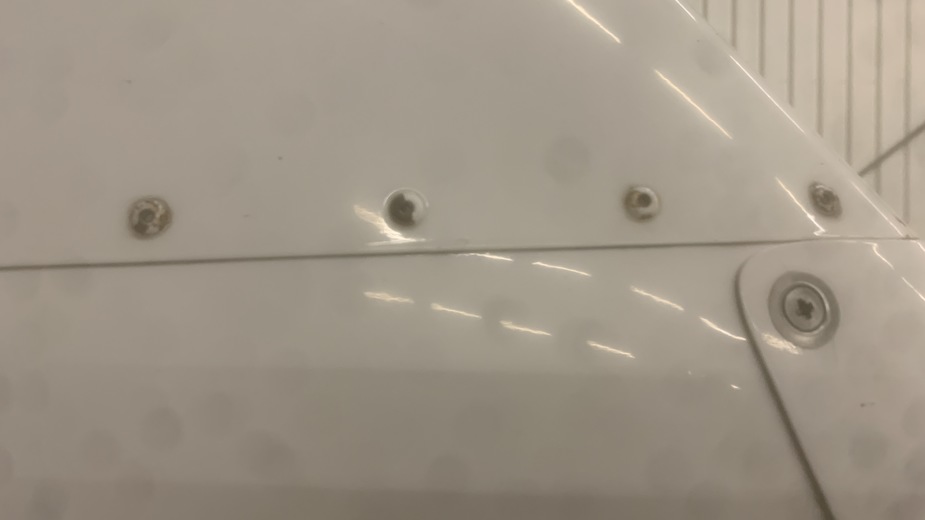

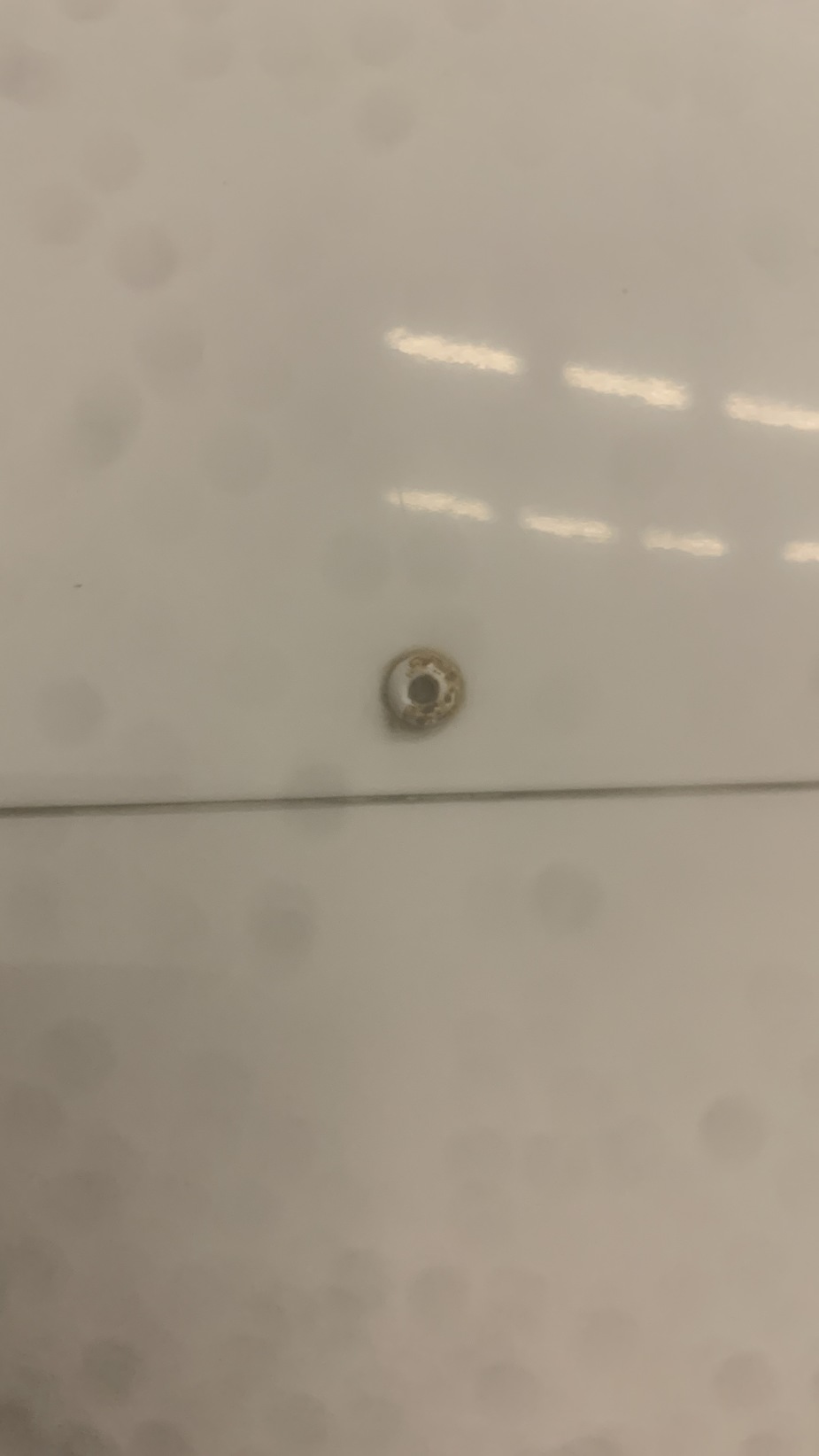

If the rivets are still tight, the procedure would be to clean them of corrosion products manually, then apply brush-on chromate conversion coating, then paint them over. Don’t forget to look at the same places from the inside.

If the rivets have worked themselves loose and are “smoking” (have a smoke-like dark halo around the head), they ought to be replaced.

Dear all, after cleaning and inspecting one detects minor signs of corrosion. Here eg of some rivets. What do you recommend to stop corrosion in this stadium?

A common reason for elevator corrosion is that instead of using the correct control lock (which holds the elevator with the drain holes at the bottom) people tie the yoke with the roof rack type of elastic bands to the seat and then a part of the elevator fills up with water.

This is a problem with many types, not just TBs.

Usually the corrosion is much worse than the above photos show. I have quite a collection of photos from years past which people sent me. Like this one

One needs to use ACF50, every year or two, and it may need the drilling of some holes at the two ends of the elevator so the spray nozzle can be inserted, although it can be done without that.

I don’t know to what extent Socata co-operates with repairs. I know for a fact that the vertical stabiliser is regarded as a “critical” part and no repairs are permitted by Socata. This is probably a fairly typical European restrictive practice… There is/was this AD.