The Ebay tool arrived from the USA, astonishingly delivered by Yodel which last time tried ~25 times, at various times like 5am, and going to just a random address at the same postcode

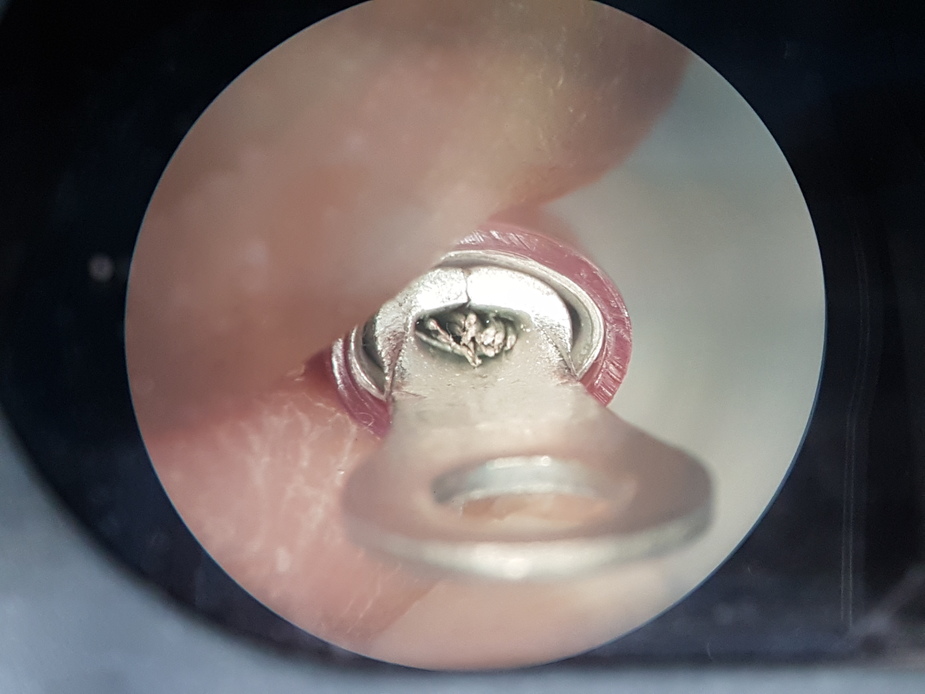

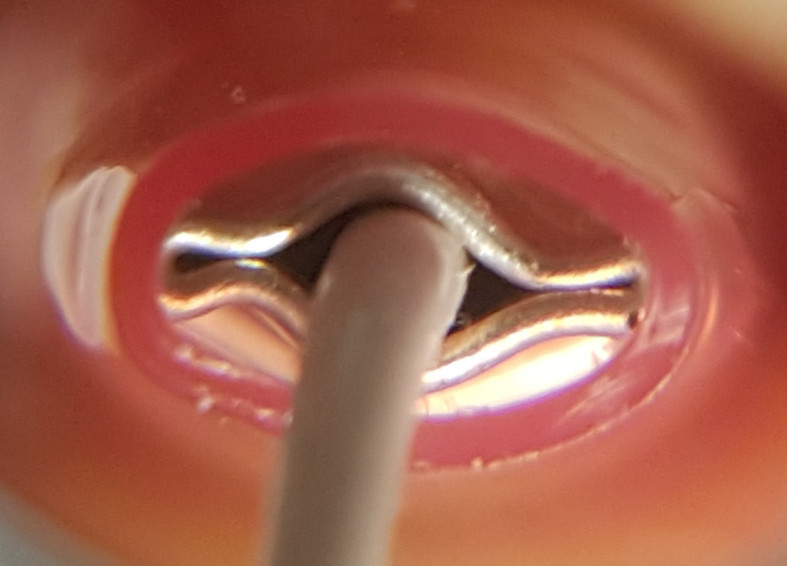

It has an interesting thingy on it whose purpose appears to be to allow the terminal to drop in just the right distance. It makes it a bit fiddly to get the wire in but it works.

The results are great… a pity I have just finished reworking the entire CB panel

I now have a pile of the French (ETA) CBs for sale… mostly the non-pullable ones.

Peter wrote:

I now have a pile of the French (ETA) CBs for sale…

Did Basque terrorists make circuit breakers?!

Peter wrote:

It has an interesting thingy on it whose purpose appears to be to allow the terminal to drop in just the right distance. It makes it a bit fiddly to get the wire in but it works.

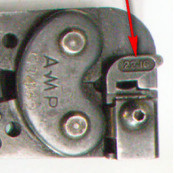

The guide in your picture is on the ring-terminal side of the crimp tool. The open wire barrel goes on the other side where the adjustable insulation crimp jaws are!

That’s really funny since it seems to do just the right thing

This proves that crimping is superior to soldering since it protects against stupidity

I am totally unable to pull the wire out, even with two pairs of pliers.

I have just realised that above I posted the same crimp tool pic twice. Corrected.

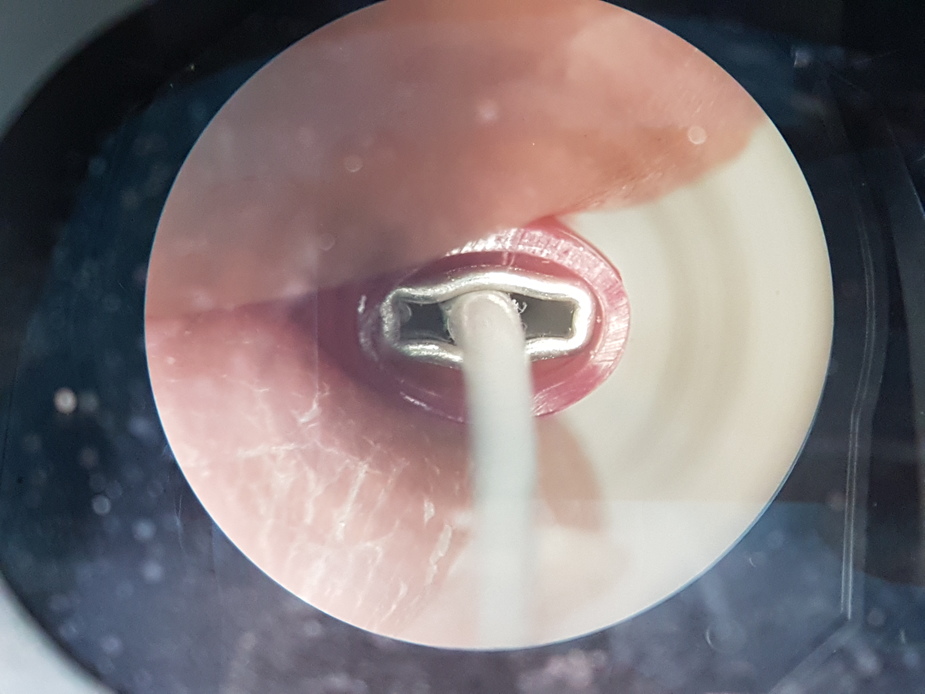

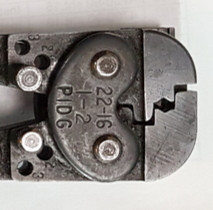

So this

is for the wire crimp and this

is for the insulator crimp, which is adjustable with the two pins, for different wire outside diameter.

That terminal BTW is RS 457-5097 which appears to be a standard TE/AMP part.

Using the crimp tool the right way round produces a similar result for the wire but a better result for the insulation crimp:

For crimps on my bicycle lights I used to tin the crimp terminal then crimp then heat then crimp again then use heatshrink – the terminals I bought came without plastic sleeves. Sometimes I left the leads a bit long and just soldered the tip into the crimp terminal hoping that solder wouldn’t wick far enough up the wire to cause problems.

My reasoning was that my crimping didn’t seem very reliable and I hoped this would give me the best of both worlds. I’m not suggesting the technique for aircraft use, but am relieved to discover I’m not the only one to find crimping seemed harder than it should be!

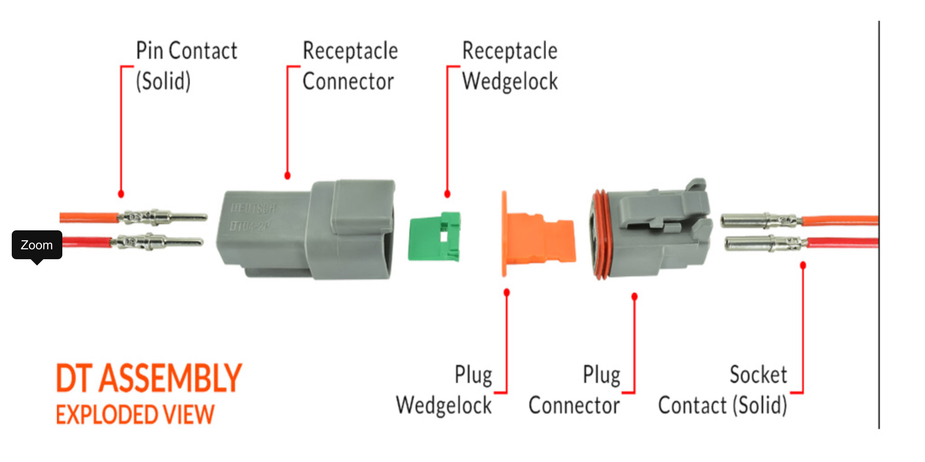

I helped an A&P recently do some avionics wiring on a Robin. Robin use Deutsch terminals from the automotive world which I found quite good. They have a very clean crimp system, a waterproof seal, good flex stress relief and a nice locking mechanism.

I ordered a box and have used them in my heating mat project. the pins were stamped cheapo stuff, enough for just heating, but with the right budget one can get some beautiful gold plated machined ones.

What do you think?

I use at the moment the Deutsch DT, DTP, and DTM connectors for a rewiring of my classic car’s cable harness. I ruled out the stamped contacts from the start and invested in a proper crimp tool (Daniels DMC AF8) with the adjustable positioner for the machined contacts.

The good thing is that I can use the same AF8 frame also either with the adjustable head or even a proper turret for the future aircraft wiring; There’s also the little bit cheaper Deutsch HDT-48-00 crimp tool which looked to me as an AF8 frame with a fixed positioner. Seems to be offered also with a starter kit and could also be an idea.

For me, the choice of the DTx series connectors was driven by a commonality between higher-density signal connectors (DTM series) up to higher-current capable DTP-series connectors that spans (apart from the battery and alternator contacts) everything I need in an old car and probably on a plane as well.

Pressed contacts are awful, although they are used quite a lot in avionics. I recall an engine monitor coming with a kit of them. And all the edge-connector products (King radios, the KN63 DME etc) use them.

These Deutsch sealed connectors look really good, where frequent mating is not going to be happening.

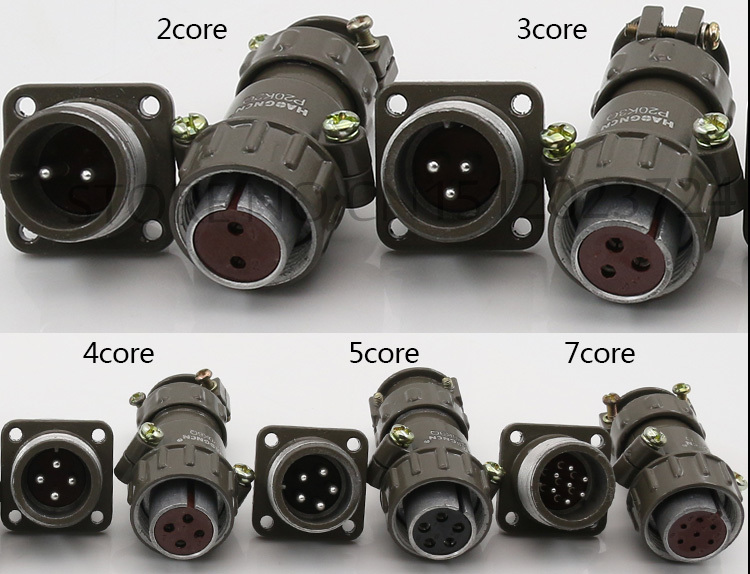

Personally I would have used circular milspec connectors, with Lemo being the tour de force option (and soldered)

If you want a water seal then the traditional milspec ones are the obvious choice but are bulkier

You can often pick them up on Ebay.

The “traditional milspec ones” are also available on Aliexpress, e.g. here

and probably as old stock in the Eastern Bloc countries (ShR or ShRG series in the old Soviet nomenclature)

On the other hand, Deutsch connectors are also watertight and are generally very well engineered without the extra weight.