I have never had a Rotax stop in flight, but I would be surprised if it actually windmilled. I believe the propeller will stop. On the WT9 Dynamic used for glider towing (Rotax engine), the engine pump suck from both tanks, but the electrical pump only from the left tank. A really stupid arrangement when towing because I have to constantly manage each tank. The electrical pump must be ON during take off, then OFF and switch to the other tank. I have already run one tank “dry” once, that is, the Dynon EMS starts screaming.

Dominik wrote:

Does this behaviour also apply for a Rotax 912 engine

The Rotax will stop in-flight. But with proper conditions restored (e.g. fuel available) it will restart with ease. I am quite used to quit Rotax engines, I’ve frequently flown a touring motorglider and having some gliding skills from when I was young I made several multi-hour cross-country flights with the engine shut down. The engine may start to windmill at about 250km/h or 140 kts, so even with emptied batteries you have a chance to restart the engine. But the Rotax starts with ease. Also had it on a microlight during final approach, that the throttle was not aligned well and upon fully idling the engine quit. Not a big thing, I would have landed without, but it sprang to life on the starter.

In AVGAS-consuming engines there’s nothing wrong to let the engine run out of fuel. I do this intentionally, for two reasons. One is to get used to engine behaviour, and to be able to read the signs (I can now foresee a soon engine stoppage on my fuel flow indicator, which will start to fluctuate a bit before the engine starts to reduce RPM). Fuel Pump on, switch tanks, and in a few seconds there is full power again. I had no Lyco/Conti so far which would have quit on fuel starvation (contrary to the Rotax), so it’s a bit of adrenalene, but in reality a non-brainer.

Second reason is, that most fuel gauges I’ve come across are so bad that they just cannot be used for in-flight usage. Those in Pipers are especially bad – although I am reading about how to recalibrate the installed ones. And by running the tank dry, I know exactly what amount of fuel was burned and can calculate the fuel burn rate with ease, especially true for the outer wing auxiliary tanks, when used for cruise setting only. So for the current settings I get the current fuel flow very precisely, and can thus extrapolate the remaining flight time.

Third point is, that I already have some reflexes in such a situation. Within parts of a second I watch the fuel flow, put on the fuel pump and have changed the tank switch to see what happens next.

I’ve read that in any Kerosene drinking engine this is not recommended. Diesels might not restart above certain altitudes as low as in the 6000 feet altitude range, and a Turbine might get killed.

Beginner’s question :

Is it OK to empty a fuel tank with the fuel pump ON ?

Or to start the fuel pump on an empty tank ?

I would think it could make damage.

Jujupilote wrote:

I would think it could make damage.

You don’t mean to run the fuel pump dry for minutes. The fuel flow will mainly cool the fuel pump, AVGAS is quite bad in lubricating things. So the fuel pump has some grease or oil inside for lubrication of its bushing.

With lots of engines upon start on ground you first switch on the fuel pump, and depending on the leak tightness of the system / bubbles on hot start and so on it will run dry for a moment. So no difference here.

I would advise knowing your engine and thinking things through before experimenting with fuel starvation.

My friend was doing a some aerobatics in his Cri Cri. He did a loop and of course the engines stopped because the carbs were not the type for inverted flight. He was used to this in other aerobatic aircraft but what he had forgotten or had neglected to brief himself that the Cri Cri’s engines are started by a pull chord on the exterior so if you can’t get the props to move in the wind, you’ve got a problem:))

Fortunately a Cri Cri is easily landed on a very short piece of field.

Try on the ground, try at 6000ft overhead (not above/not bellow) an airfield with 2km runway and then make your own mind, you will find it’s easy as hell if prop stays at high speed but it’s unnecessary risk to pull those useless last 2USG full of dirt & sediment on cross-country, unless your time to be overhead your planned en-route fuel stop with empty tanks…

Most likely the electric fuel pump ON is unnecessary for restart unless you lose the engine driven pump, or prop stops rotating faster, or lot of air get sucked into your fuel lines

Pumping air into dead engine & engine will not hurt anything, it’s a healthy thing: the SOP is to jump with fuel pump ON when you get blurps from fuel vapour locks in warm days above 8kft

When you pull mixture on ground after a flight, engine driven pump will send less and less fuel…

Is it OK to empty a fuel tank with the fuel pump ON ?

Or to start the fuel pump on an empty tank ?

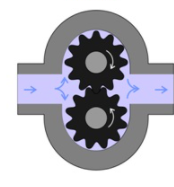

It’s a very good Q and I wonder whether the reasons for the electric fuel pump are another one of the many GA OWTs. On Lyco engines is AFAIK always a gear pump

(on fuel systems without a return to the fuel tank, there is a spring loaded bypass, to produce a constant output pressure) which isn’t really going to do anything useful if there is no liquid coming in. It will pump gas/vapour but very poorly (anyone tried priming any kind of a water pump will know – takes for ever and works much better if you can pour a bucket of water into it, with the inlet closed, get it running, and then quickly open the inlet).

Hence I think the recommendation to run the pump when switching tanks, regardless of whether you expect a gap in the inlet fluid flow, is based on pretty flimsy evidence.

IMHO most of the purpose of the electric pump is a backup for the engine driven one.

We did this a bit here and with no conclusions.

“to pull those useless last 2USG full of dirt & sediment on cross-country,”

The fuel tank should have a finger filter, for large FOD. This is raised above the sump, where the fuel drain is. With turbulence, I wonder how much muck accumulates in the sump. What passes the coarse finger filter should be stopped by the gascolator.

If the plane has not been flown for a long time, I’d drain more fuel than usual befor flight.

And mogas deteriorates quite quickly.

Ibra wrote:

it’s unnecessary risk to pull those useless last 2USG full of dirt & sediment

Isn’t that the unuseable fuel?

Not referring to unusable fuel but I am under the impression fuel quality is not the same between the first USG and the last USG, 1/ if they are the same and fuel is homogeneous: then it’s good, 2/ if first USG quality is bad: the engine would stop on the ground, 3/ if last USG quality is bad: the engine stops in the air

Most likely 1/ is true as Maoraigh said due to turbulence and mixing but I hate getting 3/ wrong

I don’t care about 2/, I am on the ground doing power checks