My GEM is showing the need to replace sensors and/or a complate system. Any advice on how to test sensors and the display would be appreciated. If I have to buy sensors etc. should I change to a newer system in total, any suggestions please? What are the possible cost implications?

Thanks

What is the GEM showing?

There are 2 sensors out completely on cylinders 1 and 6 and others I see may be a little unreliable. The difficulty is knowing what and how to test before deciding what course of action. A complete new system has been advised but sometimes it is not necessarily the right solution. Yes a new system will work but maybe the existing one will with a lot less expenditure than new.

Do you mean you have multiple EGT or CHT sensors showing up as faulty?

EGT sensors do fail, due to hot gas erosion, although it would be very bad luck to see more than one go suddenly.

CHT sensors almost never fail because they don’t get very hot.

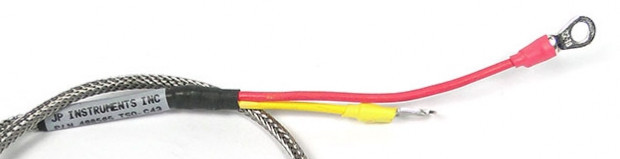

You might have a cable harness coming apart. The sensors come with a short lead, about 0.5m, and there is a joint comprising of some tags and screws+nuts.

Otherwise, the connector may be loose on the back of the instrument. Or you have a duff instrument.

The probes are easy to check. Connect a voltmeter to the probe output (probe dunked in some hot water) and look up K-type thermocouple chart for the voltage. But if you have several it is probably not the probes.

If it was me I would try to borrow another identical instrument, because rewiring the probes can take days.

Thanks Peter, I will investigate further before making any assumptions

Do a close visual inspection of the probes and the wiring all the way back to the instrument.

If say EGT #3 is duff then locate that EGT probe and follow the wire back. About 0.5m back you will see the above joint, in a sleeve, so open up the sleeve and check it is tight.

If the instrument is saying OPEN CIRCUIT PROBE or some such, short-circuit the two probe terminals at that joint and the temperature reading should fall to zero, or close to it. This test works because O/C thermocouple detection is usually done with a pullup resistor which generates an abnormal voltage across the terminals of an O/C probe, and if short that, you are simulating a good probe whose tip is at the same temp as the back of the instrument.

If you don’t get a zero reading, work back the wiring. Most likely, if the job was done right, the next joint will be in the connector at the back of the instrument.

You might find that a cable harness is being cut by a control linkage, which is pretty scary when you see it. I had that after a TCAS installation by a top 145 shop  So sort out at least the visual check ASAP.

So sort out at least the visual check ASAP.

Which Insight GEM Model do you have ?

The later Models perform automatic probe checks that help to troubleshoot the problem.

The older Models seem to not hold up to well over time – I just replaced 2 in a twin for this reason.

I am pretty sure that every thermocouple instrument ever made has open probe detection. It is just one pullup resistor; usually about 10 megs. And shorted probe detection is impossible

What worries me about my EDM700 is the connector on the back of it. It is just soldered straight into the PCB with no support – very flimsy.

The GEM G4 is just as bad.

So it seems from my engineer that a replacement is needed, and since we may have a totally fresh start I would be interested to learn from others what they prefer and why.

Thanks in advance.