Hello guys,

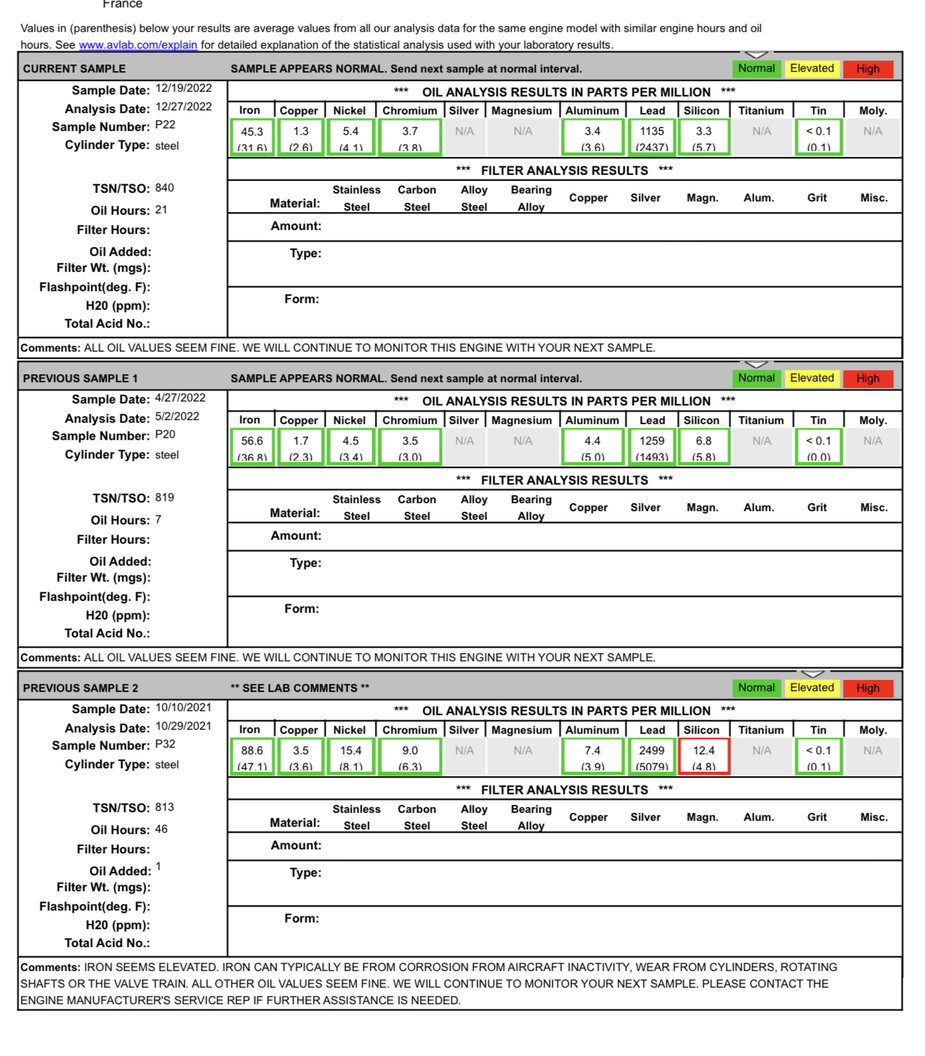

I’m looking at buying a plane in a close futur and this nice HR100 got my attention, but after receiving the latest oil analysis ,it doesn’t look so appealing. I think the plane seems not intensely used and suffers from corrosion, but I can’t evaluate this correctly (apart the comment from the lab).

Any help is welcome.

Looks to me like the plane was not flown a lot in 2021 (excess iron) and was operated from somewhere dirty/dusty (excess silicon is just soil) back then.

The corrosion would, if heavy, jack up the soft metals (copper, aluminium, etc) but it has jacked up only aluminium which is probably corrosion in the cylinder bores.

2022 data looks fine. Chromium (wear on camshaft and crankshaft etc) came down nicely.

Lead is from avgas and is just proportional to how much avgas went through the engine.

The warning comment is only for the sample of October 2021, later samples are fine, and this one isn’t critically high either. I would not worry about it if there are no other warning symptoms. In any event, it is highly recommended to have a pre-buy inspection done by a maintenance engineer – there are lots of things that can go wrong and many of them aren’t very obvious. If you already know who will do your annuals if you buy this plane, talk to them whether they can do a pre-buy and credit it towards the next annual (assuming you get it done shortly after purchase).

If it is a HR100-210, you are hopefully aware of the hot-start behavior of the Conti ? Requires skill & patience… a lot.

And the tank management, since the Conti pumps through large volumes of avgas and send excess always only into (IIRC) Left Inner tank. Requires attentive tank management.

Last not least – you are unlikely to find a certified AP and the pneumatic Crozet is not known to an living engineer.

I liked the HR100 a lot (apart from the above)

Indeed I know these issue, apart from that very old AP but this HR100 is not equipped with it. Century was also available as an option at the time.

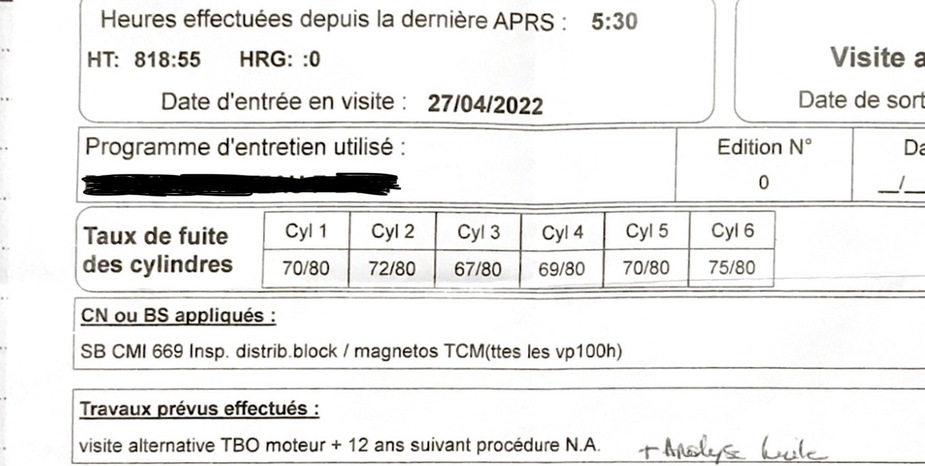

A bit more about the engine, some cylinder are a bit low.

I need to find someone for a pre buy, but have an idea of the place to have it maintained.

This pane is currently maintained under MIP (minimum inspection program), the work is done into what seems a reputable place. I don’t have yet access to it, but so far the element looks good.

Greg, check out Mike Busch’s videos and books about compression – these are not necessarily bad numbers.

Mine was under CAMO in Chambley – not a place I can wholeheartedly recommend. Annual (they knew the plane) took much longer than promised… and they did not tell me until I was there…

Not to mention the inflight engine stop after they replaced the fuel lines…

As per previous post, not necessarily a compresdion problem. Conti requires less than Lycoming and I presume you don’t know the circumstances of the measurement (hot/warm/cold, run lean/fat before, retested after running, etc.)

Actually I would run after a 200 version as Lycosaurus bears flight hours better than the conti, and has 2000hour+ extension on the TBO, for a reduced advantage in power, in exchange of a reduction in autonomy – not something needed on this plane, but roughly easier to load with the fuel.

Another issue is the rarity of this plane, there is hardly a STC available for it (I was interested by EI)…

I’ll have a better look at Mike Busch stuffs, Actually I was very interested in motorcycle, car and high performances engine, and a porous cylinder is something I consider as an issue; but here we are dealing with engine coming during the 60`s…

Maybe someone can help me out here.

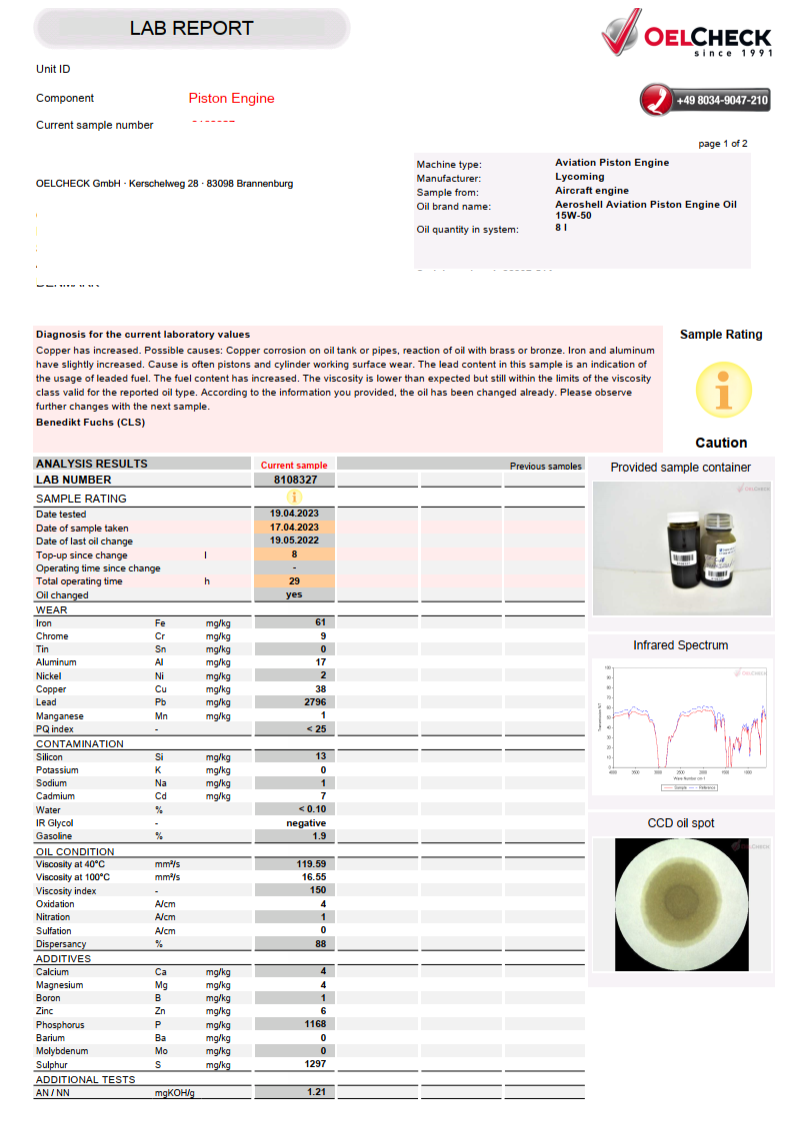

Got the oil sample from the pre-buy yesterday.

And wonder if this is a Red Flag?

Should I walk away or if it “SAFE” to continue.

Maintenance shop said we don’t like it, but it’s not alarming high…

Lycoming IO-360 C1C6

250h SMOH

50h since Prop Strike with Shock load.

The Copper is high, but if I understand it’s normal when using Aero Shell 15W50 + Camguard.

Even if it’s on the high side.

But Iron and Aluminium is also high?

Maintenance shop said we don’t like it, but it’s not alarming high…

I concur

Copper is on the high side, but so is iron. This points primarily to an engine not used as recommended by Lyco, regarding frequency and time.

So, whilst these, and other, values are on the high side, it is difficult to appreciate the state of the engine based on a single oil analysis done by a laboratory with little aviation engine experience. Oil analysis is one of the tools used to show the history of said engine.

The use of 15W50 + Camguard should not produce any higher copper readings… at least they don’t in my O-360-A1A.

Other items such as oil consumption, compression, and borescope inspection should help in ascertaining this engine’s health.

Red flag no, more kinda pink