I would start by removing the three screws …

There is not enough information to comment, as said above remove the three screws and we can take a look at the back of the unit.

Due to the angle the photo is taken from I can’t tell if it is front lit with a thing called a Nu-Lite.

……… remove the ASI from the panel and all will become clear.

It’s one of those jobs someone working on aeroplanes every day will do, and if you watch them you think that looks easy.

I was helping a mech yesterday hang the barn door flaps on our 206, he had a special pliers/bent spanner/locator tool and a step of exactly the right height which allowed him to jiggle the rollers into position with his knee. He had a special flex magnet in case a roller dropped into the flap. He knew the exact sequence of bolt, spacer, roller, washer by glancing at the manual and McFarlane drawings. Someone doing it for the first time would take 3x as long.

Taking out the ASI, easy enough. Putting it back in and connecting it back up with no leaks and not disturbing anything else I guess is slightly harder. I never envy the task of an avionics technician having to do such fiddly work lying on their back working over their head in tight confines. Let us know how you get on!

Figure out what device it is and grab a manual from the internet?

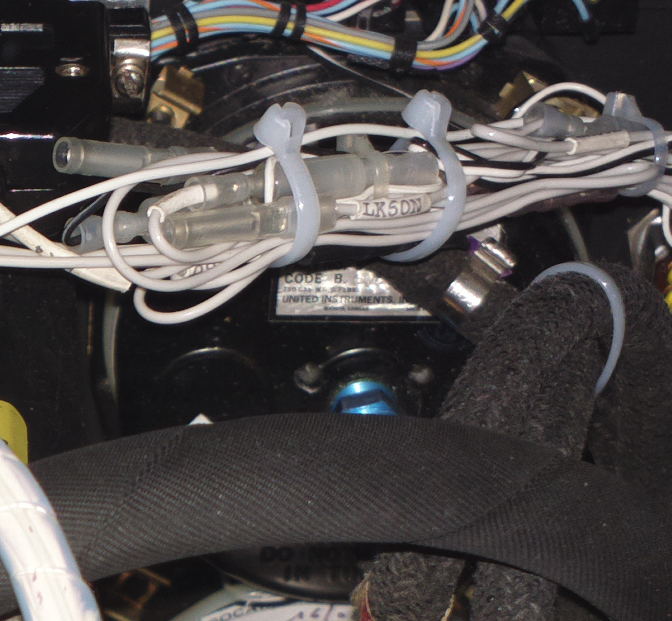

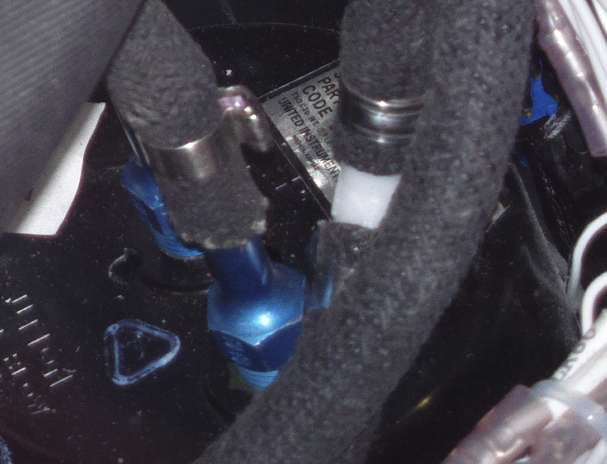

These are the best pics I can quickly find of the back of the speedo

It is a common cheap and dirty United Instruments product – same as a lot of the steam gauges used in GA. All the TB20 illuminated steam gauges used normal light bulbs – 12V in the old TBs and 24V in the newer ones.

It has just the two pipe connections and two wires going to the bulb. From vague memory the bulb is accessible from the side and the location is evident when you pull it out.

The TB panels tilt so access is pretty good. The LH panel has an extra catch which is reached by poking two fingers through a large hole under the yoke, roughly where your knees go. However some % of planes have been bodged by various avionics shops and they have brackets / struts / instrument supports fixed between the backs of instruments and some part of the airframe forward of the tilting module, and you have to unscrew these before you can tilt it. Also more planes have bodged wiring which also makes it impossible to tilt it and that is worse. You won’t likely be able to extract the speedo far enough to change the bub without disconnecting the pipes, but I could well be wrong, so it’s worth a try first.

Make sure you do a really good full and free controls check afterwards, with a light and a mirror looking especially at the forward portion of the yoke tube which passes very close to the bottom of the HSI.

You won’t easily find any MMs for these online. They are closely guarded and exist only in instrument repair shops. Unless you get lucky… I have never seen one. Just looked in my huge avionics manuals stash and nothing there under “United”.

BTW I have been re-doing the air pipework behing the panel. The Socata tubing cracks after many years.