I recall seeing some amazing kit in the Aircraft Spruce catalogue - for the US Experimental market, and presumably OK for a UK homebuilt like yours, too.

Oddly enough the May 2013 issue of the US AOPA magazine has an article on somebody installing a B&C backup alternator on a Mooney M20J.

Regarding the removal of the vac pump (and presumably the removal of the vac AI even though it doesn't actually say that) they suggest first checking the TCDS to see if a vac pump is mandatory.

If it isn't on a TCDS, they say you just need "a shop to sign off on a 337 as a field approval". But surely that is nonsense? You don't just get "a shop to sign off on a 337 as a field approval". The 337 has to be signed by an AI and then has to go to an FSDO to be approved... or does an FAA Repair Station have the authority to sign a 337 field approval in-house? I am pretty sure it doesn't.

Anyway, if not removing the vac system, it is going to be a field approval unless there is an STC. A Major alternation in any case.

But this man had a helpful FSDO on his doorstep...

They also say something about an unusual "tachometer" having to be installed. I suspect they mean the actual "alternator".

There was a posting on the mainly-US Socata owners' site where this topic came up. One man (not a TB owner) says that to fit one of these B&C units you sometimes need to relocate the vac pump and the engine accessory case has to be machined to take a hydraulic gear pump adapter.

I emailed B&C to ask if they know anything about this. Their email comms is fraught with problems. They are rejecting all my emails as spam. Only fax, or messages sent via their web enquiry form, get through. I faxed them the bounces but they don't seem interested. The one reply they did send doesn't comment on this and just says they have not had any owners share a 337 with them. They sent me one of their STCs and that was it...

I asked them for a dummy unit so I could see if it fits.

Obviously having to machine the back of the engine would make this a little more than a simple job

Update: they are sending me a mockup unit of the BC410-1 for fit testing. I just pay for the shipping cost.

B&C have been endlessly helpful and co operative, as I work to STC the installation of one of their standby alternators on the 182. Engine drive pad change is required, I'm working through that...

Does the engine drive pad change require engine removal?

The pad change can be done with the engine in the mount, however, it will be necessary to tip the engine or mount forward to install the alternator onto that new pad.

I am probably missing something here, but isn't the B&C alternator mounted the same way as a vac pump i.e. there are four studs sticking out of the accessory housing and the pump/alternator screws onto those.

I have one unused vac pump drive location, which has a little cover screwed down using the four studs.

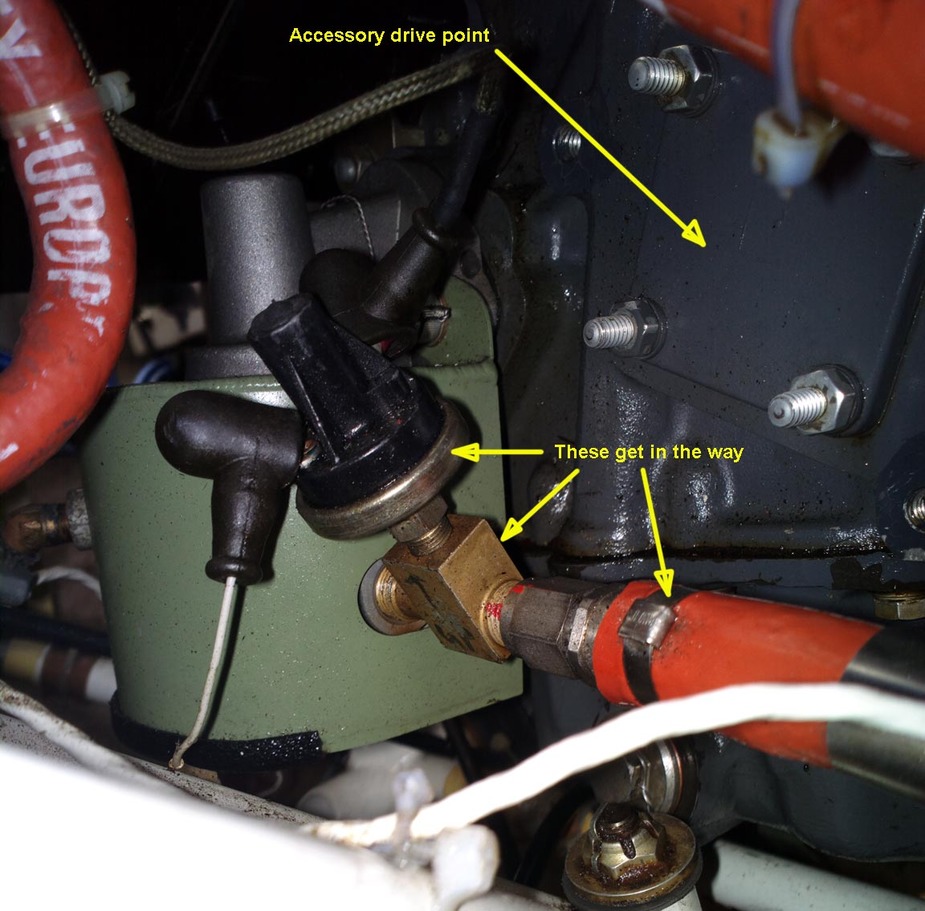

In reality getting to the four nuts can be a pig of a job, and in my toolbox I have two "special tools" for getting to them. One is a strangely bent spanner called something like "crow's feet" and the other is a modified screwdriver for holding the nut in place for long enough to get it started.

But that isn't the same thing as needing to tip the engine forward to get the alternator in place, which suggests that there isn't enough room behind the engine, but that will presumably be installation dependent.

The B&C alternator "mockup" unit has arrived

Weight 2.6kg.

I will see if it fits.

We've had a few threads on this generally 1 2 3 but I am starting one on the TB20 specifically.

I got a "mockup" of the B&C unit from the USA, free of charge provided I paid for the carriage

This is the spare vacuum pump accessory drive on the back of the IO540-C4

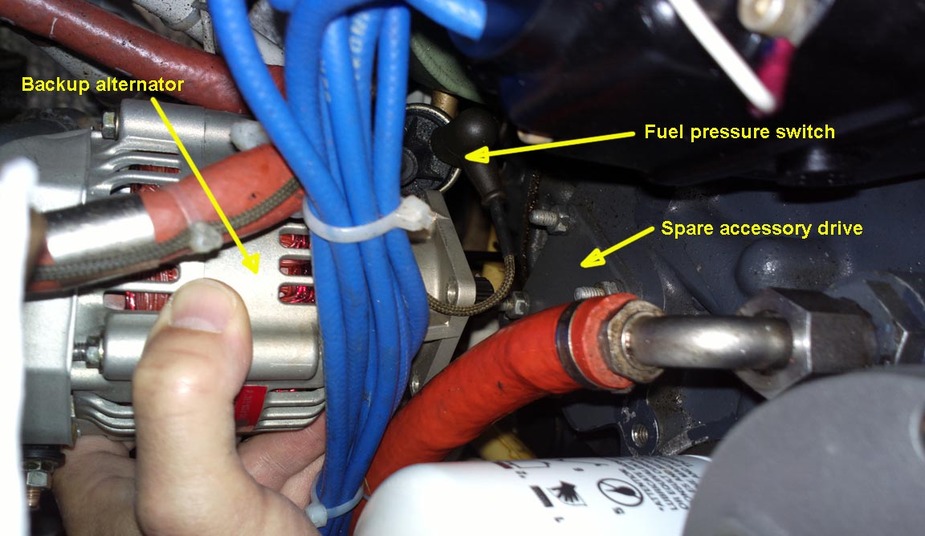

Placing the alternator into the location reveals that it hits a fuel pressure switch mounted close to the inlet of the engine driven fuel pump

This is the offending part

Fairly obviously one could solve this by fitting a 90 degree elbow into the fuel pump, mounting the fuel pressure switch on the inlet side of that elbow, and relocating the fire-sheathed hose appropriately (the hose may need to be longer).

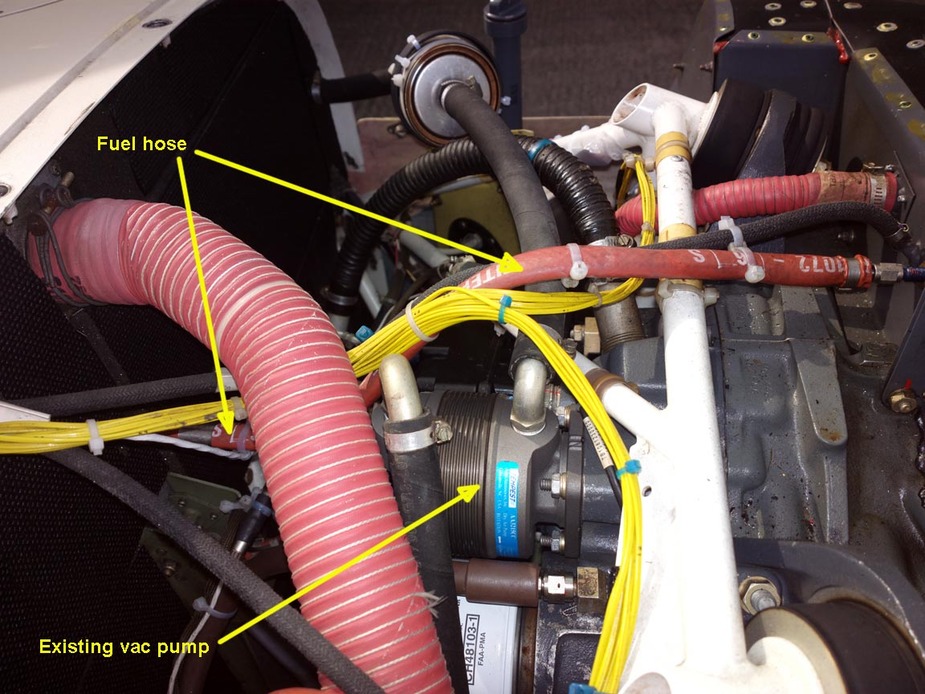

It has been suggested on another site that fitting this alternator in the TB20 needs the existing vacuum pump

to be moved to the spare accessory drive location, and mounting the alternator where the vacuum pump used to be. But that cannot work since the diameter of the vacuum pump is still too great and it would also hit that fuel pressure switch. So it doesn't sound like anybody has actually done it...

The alternator could be mounted in the vacuum pump location but it would hit the fuel hose which goes from the fuel distributor to the cockpit fuel pressure gauge, shown in the above image. This hose could be relocated however.

An "interesting" complication is that both the above mentioned hoses are most likely ISO-thread (metric) and a pig to get made. If you go to an Eaton hose dealer, he will have to go the only bit of the Eaton group which makes these fittings, which is Aeroquip in (yes you've guessed it) France and I think that when they guess that this is for a Socata they try to fob off the enquiry by doubling the lead time, to around 20 weeks.

I have the mockup alternator for just 30 days but since I cannot progress this project until I the next time I have hangar access for a few days at least, I will try to get this loan extended till the Annual.

Are you planning to go the STC or the 337 route?

Relocating the hoses is simple, every A&P knows by heart how to do this. Some shops can make hoses in house. Your brass T-fitting looks handmade, my shop created a similar one for me.