The FAA has issued an airworthiness concern sheet to request information from operators of Cessna 177 and cantilever-wing Cessna 210 single-engine airplanes about any known cracking of wing carry-through spars following a fatal Cessna 210 accident in Australia caused by fatigue cracking.

The airplane involved in the May 26 accident, in which the right wing separated in flight, crashed during a geological survey mission, killing both occupants. Investigators issued a preliminary finding that wing-spar fracture was caused by fatigue cracking. The accident airplane has been modified for geological survey work, including a tail boom, integral wing tanks, installation of specialized equipment in place of the rear seats, and a “non-standard engine and propeller installation.”

Nice of them not to ground the fleet as a precaution and order inspections worth more than the airplane…

Mooney_Driver wrote:

Nice of them not to ground the fleet as a precaution and order inspections worth more than the airplane…If I owned one I wouldn’t be flying it till it had been looked at

Mooney_Driver wrote:

Nice of them not to ground the fleet as a precaution and order inspections worth more than the airplane…

Given the very low risk, I think owner reaction to this will generally be no action (wait and see) or maybe a little extra inspection at the next Annual, particularly for commercially operated 210s. It’ll be interesting to see if cracks are found in other aircraft as some owners take a closer look. My aircraft type had a similar incident in the 80s, an emergency AD issued grounding the aircraft, removal of official aerobatic certification forever and subsequently an AD requiring immediate eddy current inspection, repeated every 3000 hrs. No crack in any other aircraft was found at that time, and none has occurred since! The potential sample size for cantilever wing Cessnas is tremendously higher so maybe there are enough similarly hard worked aircraft out there that another example will be found.

Neil wrote:

If I owned one I wouldn’t be flying it till it had been looked at

Big difference to grounding and having to dismantle the whole airplane before you know.

The airframe which is the reason for this thing was highly modified which I believe is the reason this did not become an AD.

Well, most of the story is at the ATSB prelim report and subsequent update

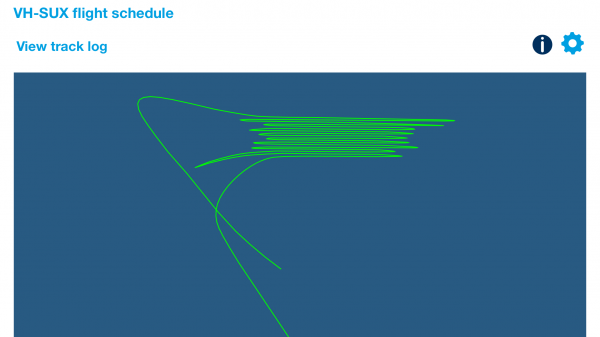

To put it in context, the accident airplane had been flying 1000hrs/year for six years in a row of a very specific type of survey operation which involved multiple parallel 200ft-spaced 50-70 mile runs at 200ft AGL at high speed with course reversals of who knows what type at the end of each run.

See an example of the radar track log from the BT forum:

Wing structural load distribution was not standard 210 since they had extended wingtips as well as some heavy survey equipment in the fuselage and the tail.

There was a former AD 2012-10-04 requiring inspection on the wing spar of these aircraft prompted by cracks found by this and other Australian operators some years ago, but that was in an apparently weaker member of the wings structure (a spar cap skin attachment) rather than the massive carrythrough forging, which one would think would be more robust. Cessna tested the spars during the analysis for the AD and even after the offending member was completely cracked through the spar was found capable of carrying full design load since the crack apparently would not extend beyond the said member.

Cessna and the FAA played safe though and decided that flying around with cracked spars was not a good idea and hence the mandate remains.

As to the carrythrough forging whichi is the subject of the OP, this is is the member connecting the above spars from LH and RH wings through the fuselage and is a much more massive structure:

It is thought the crack may have been corrosion- initiated and hence the inspection is meant to find and correct corrosion, look for cracks and corrosion-protect the part.

The crack inspection is eddy current and under normal operation is required within 10 hours for aircraft having a total of 4000hrs or more under normal use. under FAA rules, any A&P can sign off the inspection performed by la level 2 or 3 eddy current specialist. I believe Michael Chartier at LFPN is gearing up to do it and once access is gained, it should be a four-hour job max, so not overly expensive.

Most of the private-use fleet is between 2000-5000 hrs TT by now. Quite a few workhorses are above 10000hrs, but this type of use also drives an earlier inspection threshold.

Effectively this all but grounds all of the fleet above 4000hrs from Cessna’s point of view, since 10 hrs is all the leeway they are providing. Of course while it isnot an AD fly-on is at owner’s discretion under N-reg, milage may vary depending on your maintenance program under EASA reg.

Nothing is to say this will not end up becoming an AD.

Everybody thinks normal 210 use should not lead to this type of failure, but it is nonetheless a good idea to ensure there is no corrosion on this major structural part, for which there is no alternate load path, unlike more modern designs like Cirri, Diamonds and Cessumbias.

I will continue happily flying the family in our 210, but even though my airplane is well under the inspection threshold, we have nonetheless already carried out a prelim visual on the area for corrosion to be on the safe side.

We should expect that within the next few months the whole fleet above 4000hrs will end up having been inspected and we will then know the full extent of the issue.

My bet is there will be no crack findings outside of this very specific type of operation.

I wonder how many aircraft types would survive this kind of abuse…

FWIW, I just had to deal with that issue wrt to the C210L our club operates. We are having the inspection done on Monday. Fingers crossed…..

As @Antonio says, normal use of a 210 shouldn’t lead to this kind of failure. That said, I have seen how 210s are operated in Africa and Australia, where they are real workhorses, and my guess is that the picture in these places may well be very different.

I’ve been told that the inspection being mandated for P210N planes is already included in SID53-11-02, so planes that have the SIDs done would be covered already.

lionel wrote:

I’ve been told that the inspection being mandated for P210N planes is already included in SID53-11-02

That turns out not to be completely correct. SID53-11-02 inspects a different part of the same piece of metal.

lionel wrote:

That turns out not to be completely correct. SID53-11-02 inspects a different part of the same piece of metal.

Correct. Essentially one covers the top, the other the bottom, confused us also at first. We then had our C210L done according to the latest info last week and found (breathing deep sigh of relief) the spar to be in mint condition.