Peter wrote:

Not easy to poke it bang in the centre of the dipstick hole, and then you have to, ahem, suck it out. Maybe Ann Summers sells a battery powered pump?

Just get a large syringe. I keep a 20 mL one in my toolbox and it has helped me in many different situations.

These are useful for lots of stuff.

They are very common in marine use where the sump is almost touching the hull in the bilge.

Or half life oil changes where you may be happy to spend 3 mins to remove and replace the oil in something that you can’t justify doing the filter. Ie motorbikes, lawnmowers.

When I’ve had the Conti serviced I use it to remove oil before tipping Camguard in.

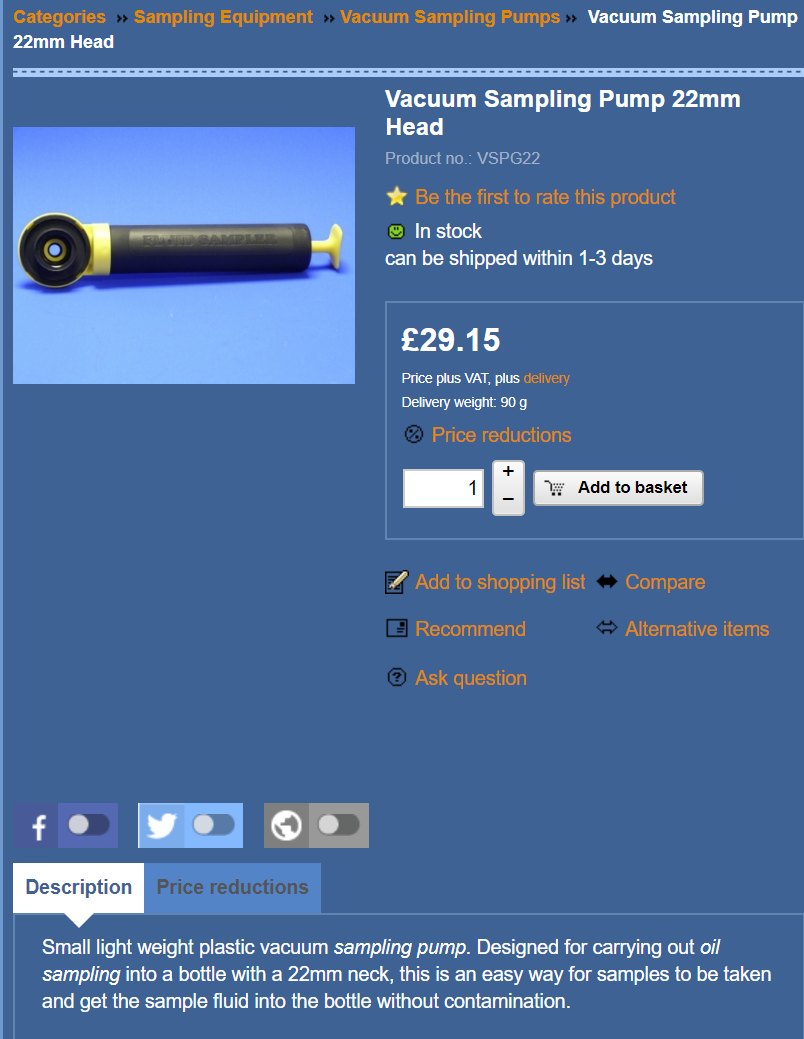

To sample oil without contaminating it, I have found these to be the best style of vacuum pumps. You thread the clean sample suction tube through the hole in the top of the pump device, screw on a bottle, and then stroke the handle to suck up the fluid. The suction is developed in the sample bottle via an orifice in the pump, this pulls the sample up the tubing and into the bottle. Unless you overfill the bottle the suction pump does not get dirty and is not contaminated between runs.

When you are done, you unscrew the pump from the bottle, cut the tube at a clean point and pull it through the vacuum pump. Repeat as necessary. Very efficient and clean too.

You of course need the correct bottles (rated for suction) and a length of tubing which is consumed as you use it and throw it away. The whole kit (in a case) is a bit more expensive, but I guess it depends on what you want. For work I use the big kit, but on my own, I would just purchase the pump to go with the bottles I intended to use and a length of tube.

For the isolated task of acquiring oil samples for testing that does look like the very best way.

Neat effective and probably quite clean too.

I’ve just read an article on sticking valves, by Mike Busch, in the US AOPA mag.

I wish I had known the content this time last year, but nobody else did so either so maybe it isn’t well known.

The main points are:

It is well possible that my #2 exhaust valve did get stuck during one long low power descent. The CHTs easily fall to or below 300F then.

That article seems to be “inspired” by this technical paper by Ed Kollins of Camguard fame.

Yes; Mike Busch mentions Ed Kollin. Ed posted here too, as @ed2.

Mike Busch gets a much bigger audience than Camguard

That is a great bit of research which explains lots of things; notably why Conti engines are now starting to see valve sticking: more and more pilots think that operating “deep LOP” is a good idea.

I’ve got very few hours in aircraft with appropriate engine monitoring capability and I would say that is a fair reflection onfthe UK GA fleet in general. I also add I have had a fair few sticking valves over the years.

So my question is what the average spam cam owner do about it?

Run it hard, lean on the ground, change the oil regularly. But how about running on UL91 wouldn’t that make these problems go away? Perhaps the little extra premium might be cheaper in the long run.I’ve got very few hours in aircraft with appropriate engine monitoring capability and I would say that is a fair reflection on the UK GA fleet in general. I also add I have had a fair few sticking valves over the years.

So my question is what the average spam cam owner do about it?

Run it hard, lean on the ground, change the oil regularly. But how about running on UL91 wouldn’t that prevent the problem in the first place? Perhaps the little extra premium might be cheaper in the long run.

I have engine monitoring but have excessively high egt before I can get CHT to 380-400 on an average cruise. I’m generally around 330-350.

Some articles say to ignore egt but at values over 1520 I start to be concerned.

After reading that article, I will admit to having wrongly learned to try to keep CHT low, as prettymuch everything else points to low CHT being good.

It’s a mine field really. I think it’s good to have lots of knowledge but you could co insane trying ro achieve it all.