FWIW I never trust low idle EGT indications…they are all over the place…but I do trust symptoms of a rough running engine!

Cylinder being removed. No compression, until the valve re-seats itself. Sticking valve. Springs fine. Valves look fine.

glad you’ve figured it out.

Cylinder delivered to Norvic.

No more IFR trips for a while due to need to bed newly honed cylinder in.

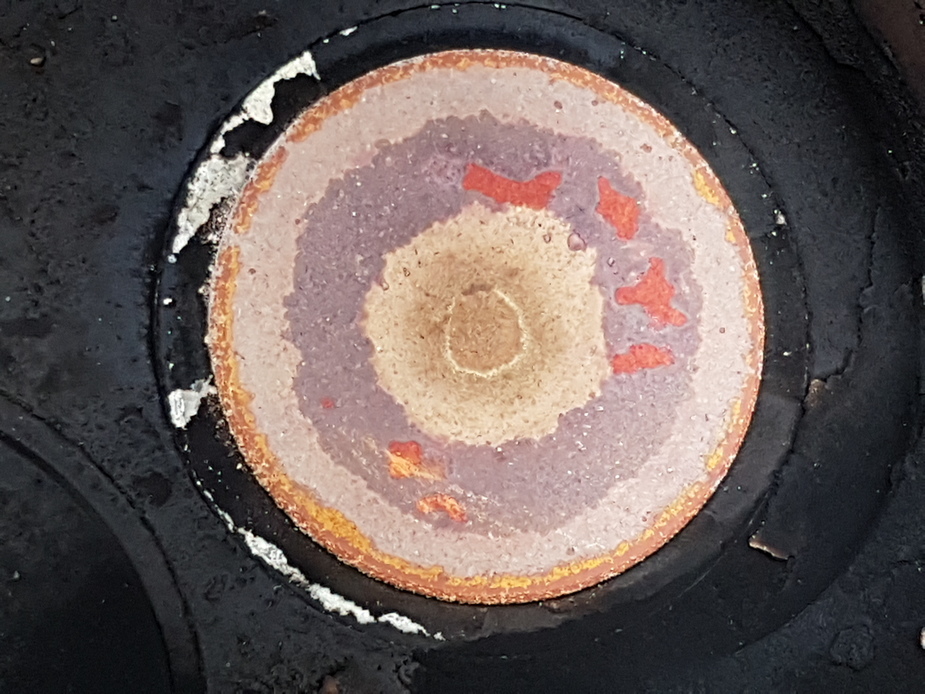

Curious red spots, like paint.

The scratches are from my fingernails.

Well, that exhaust valve does not seem to be burnt/warped, so it was only sticking open?

I am glad you got it figured out. You had to try the easy bit (injectors) before going into cylinder work…I guess you figured you could not get valve guide work done reliably on the engine

You have my sympathies, especially as rignt now there’s a cylinder off my engine, too :-(

What’s wrong with yours?

Getting the cylinder off took 1-2hrs only.

The unfortunate bit is that it will be re-honed so I will be stuck burning some four digit’s worth of avgas going up and down the coast at low level for quite some hours.

Peter wrote:

The unfortunate bit is that it will be re-honed

Why does it have to be re-honed if the problem was a stuck valve?

When piston and rings are removed and reinstalled in the cylinder, they are rotated relative to their original position in the bore.

Peter, glad you found the issue. I have the specially sized reamer to clean the valve guides on my O-320 but it’s not been used. The valves were all free when checked at a little over mid-time to Lycoming recommended TBO. If they had not been free, I was planning on cleaning the guides with the cylinder installed.

My cylinders have never been off in 48 years, and three have visible corrosion pitting. It’s easy to pull and reinstall them but I’m having a difficult time making moves in that direction given 76/80 average compression at TDC and 1 qt oil consumption every 12 hours. The corrosion probably occurred years ago when the engine was stored.

Can you elaborate on the ring position bit? I was of the understanding that rings rotate in all engines