I have previously written that experiments suggest that spark plug condition depends most on the last few minutes of the engine’s running. So if e.g. you rev it for a bit before shutdown while leaning it aggressively, otherwise oily plugs are likely to be quite dry.

However I don’t think this applies to deposits in the combustion chamber generally. I had a sticky valve repaired recently and have been borescoping that cylinder regularly (after every couple of flights – it takes just a few minutes) in case the sticking was due to something upstream e.g. a lack of oil coming up the gallery (the #2 cylinder is the last one being fed off that LH gallery).

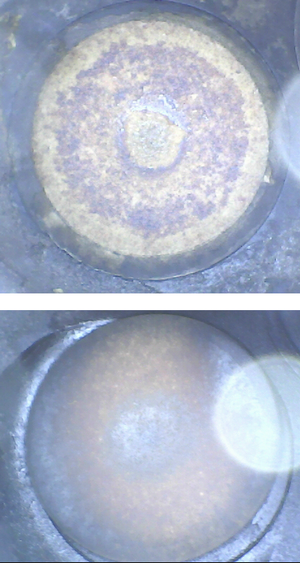

However the other day I borescoped the next one along (#4) and found that the exhaust valve looks just like it usually does, while #2 is still very clean:

Both have the same (great) compression, BTW.

I am still “running in” the newly repaired cylinder, so doing a mixture of ~85% and 65% power settings. The oil consumption is settling down.

Here is another data point. The first two are #2 cylinder, repaired with a new exhaust valve 70hrs ago. The next two are #3 which is much older and whose valves look just like the remainder

So it takes quite a while – maybe hundreds of hours – for valves to acquire their “condition” in terms of deposits, whereas spark plugs are much faster.

Most recent PPLIR magazine has an interesting article on sticking valves, especially as applied to bigger Conti and Lyco engines.

Message is clear:

1. Sticking Valves are a serious issue and can lead to destruction of engine in flight! Not good.

2. Cause is deposits of lead compounds deriving from the TEL additive in Avgas.

3. Remedy is to fly with higher CHTs

The thesis of the article as now that many of us have CHT monitors, we assume that if keeping CHT a little below the limit (380 to 400 in my engine) is good, then keeping it a lot below must be better surely.

Not so says the article. in my engine I should ensure that I keep CHTs not just below the upper limit, but also ABOVE a lower limit, in this case 350 degrees. This will ensure that the TEL is properly combusted and any deposits burnt off and out the exhaust. And on the ground lean aggressively.

This has certainly made me change my engine management. If flying ROP, once in the cruise I not keep leaning until I get CHTs in the high 350s at least, albeit still on the rich side of peak.

LOP is not an issue as CHTs will always be close to the upper limits when flying high, which is where LOP works best for me.

Don’t take this as gospel!!! Just one persons opinion.

Yes that would be this article which was written by Ed Kollin (the inventor of Camguard) and publicised by the equally famous Mike Busch, and which is doing the rounds of all aviation forums right now

As you can see, not everybody believes this theory, but my own experience supports it.

The purpose of my posting the above photos is as a heads-up to those who borescope their engines and who may think the borescope tells the whole story. Well, it probably does, but with a long time lag when it comes to valves. When it comes to spark plugs it tells the story of the last few minutes

Peter wrote:

I am still “running in” the newly repaired cylinder, so doing a mixture of ~85% and 65% power settings. The oil consumption is settling down.

How did you balance this with your long trips to Croatia etc at altitudes where high power settings aren’t possible? Should be getting mine back post overhaul in the next couple of weeks and wondering how restrictive the run-in is.

It was run in by then. That comment was in November 2019. The oil consumption had stabilised well before I did those trips in May/June (LDLO and LDRI).

Also, EGKA-LDLO, if you have tailwind, is possible at best-power all the way (about 1330F EGT) and you get a most satisfying EET

I did fly every week right through the winter, and right through the (deliberately vague) CV19 restrictions, taking care to fly on cloudy days to minimise the risk of the airport getting complaints from the locked-down population down below. Trips like EGKA-EGJA, 17th March and immediately before the flying lockdown, were done at high power too.

I was still on straight-80 then and didn’t add camguard until the EGJA return flight. That is vital. In fact I wasn’t going to add CG until much later, but did it because I could see some drastic GA lockdown coming. In the end we didn’t, but many airfields shafted their customers (and their engines) by closing while taking the 80% from the govt…

I reckon, follow the Lyco SL exactly, that takes care of the first few hours which are critical, and then fly at 75-85% (24/2400/16GPH on the IO540) and monitor your oil burn per airborne hour, and you will see it stabilise. Especially as you will have a whole engine whereas I had just one cylinder so less easy to see oil burn changes. In say 20hrs it should be done. Read this too. I am not sure you can tell the bed-in process by borescoping.

Sorry..thought it was a new thread :-|