During my last annual, my A&E suggested that my Cyl#4 valve may be due for replacement by next year, due to some green discolorations. Since my engine has 1960 hours on it, I decided to go ahead and do an IRAN to benefit from new rings, valve, and guide it as much as possible. My goal is to get to 2500 hours without any further cylinder work before engine or top overhaul. All other 5 cylinders are in great condition judging by borescope analysis, compression, oil consumption, oil analysis, and filter inspection.

The picture that triggered my A&E’s concern is the next picture below. My A&E borescope does not take sharp pictures unfortunately. I color enhanced it a little bit, so the green is more visible at the 19 o’clock position.

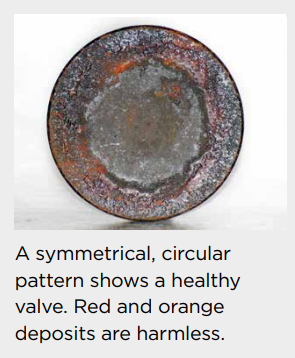

Now, that I am holding the old valve in my hand, it doesn’t look as bad, and probably could have gone for another 100 hours. The surface is not perfectly symmetric, but there is barely any greenish color. If I compare it with Anatomy of a Valve Failure, it corresponds to picture 1.

However, there is a little bit coke on the valve stem.

I can feel the coke with my finger. I was wondering how much is expected, and what is normal? There was no previous work done, so the valve has 1960 hours on it. I have run my engine for the last 450 hours at peak EGT, or a tiny bit LOP at relatively high power setting, so I any coking on the stem can not be the result of ROP ops, at least not since I bought the plane in 2013, but I don’t know what happened before my time. I never had a stuck valve during the last 450 hours, not even a hint, so I was a little bit surprised, seeing so much black/dark brown stuff. Opinions?

I was hoping more knowledgeable people would reply so to get the ball rolling. I am no expert but very interested as I Boroscope my engine every 50 hours.

I would say that your valve seemed to be seating perfectly, there is no burning around the seat.

If I saw the second photo on my Boroscope I would not be worried at all with normal lead and carbon deposits

I agree the green is slightly weird on the first shot so can others help us out?

A perfect valve would be evenly coloured all around, like a ‘pizza’. If you have a green area in one spot only, that is where the valve is starting to get burned, only a matter of time before failure or worse. The valve is cooled by the contact with the valve seat. It may be just a matter of crud in the valve seat, worn valve guide or something else. I would certainly have the valve and valveguide removed and checked by a competent shop.

Here is an article with pictures:

Curious spot on an exhaust valve

A few days ago when doing the 50hr service I borescoped the valves for the first time ever.

The borescope (an expensive SKF unit) was really hard to see anything with but I managed to find this spot on the #1 exhaust valve

It is a crappy photo (taken with a phone, of the scope’s LCD, because the flash card was full and it was a borrowed unit so I didn’t want to erase it) but it worried me. It looks like there is a deep hole in the middle. It also looks like the remains of a washer, welded to the valve! I know exactly there are just two ways a washer could have got in there (during original assembly, or something has come off inside the air duct) and neither is particularly savoury. So I came back 2 days later with this chinese borescope and it was better, and I got these pics

I also brought some stainless steel wire, about 2mm dia (a TIG welding rod actually, for welding SS) to see how deep the hole was. Bending it suitably to reach the valve, I managed to scrape its surface

and it turned out that this was just more or less a soot deposit, with no step in the valve surface.

I send this to my US engine shop and they said categorically it is fine.

What is interesting is how this forms. Presumably, with a specific combination of component temperatures, the valve stem cools its centre just enough to create this pattern.

There is not a lot on google showing this phenomenon, except this which shows something circular at the bottom

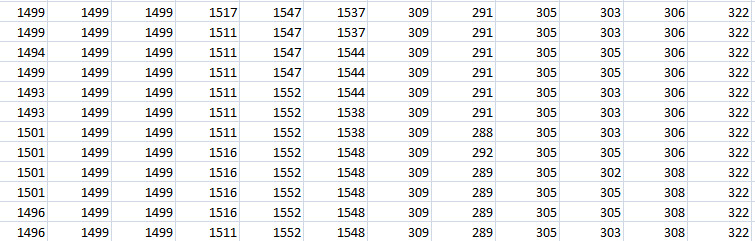

There is otherwise nothing special about the #1 cylinder. Here is the typical EDM data (in a cruise, on a very cold day)

Has anyone come across this before?

This is one of my valves taken in 2018. In my case I think in my case these are lead deposits but I burn a bit leaner these days and get less of this.

I presume the rings are due to cooling from the sodium filled valve stem?

OK @Peter or anybody else? I just did my 50 hour check today and this is a photo with the borescope through the top plug and bent 180 degrees to look back at itself. I had a brief panic when I saw these “cracks” on the top of cylinder 1. I am aware that cracks can develop between the spark plug and the valves so had a really good look.

I have inspected another 30 photos of the above and it is definitely not cracking. I’ve recently done 6 x long trips with 25 hours of flying in less than 2 weeks. I am guessing that this is probably chunks of “deposits” breaking off and like Peter’s photo, a tiny change in the surface levels looks massive. BTW Peter, I am still using the Vividia Ablescope VA-400 recommended by Mike Busch. You bought one about the same time as myself, I find the photos it takes are really good.

It is prob99 just a crack in the deposit in the cylinder. You could do what I did and stick a piece of bent wire in there and scrape off the deposit. The “crack” is about 2cm away from the spark plug hole so this should work.

Your photo of that circle in the middle of the valve is just amazing!

I never got such pics with my endoscope but there is time to learn

I also use a Vividia Ablescope VA-400 boroscope. I did my 50 hr check 2 weeks ago and while at it, replaced all my 8 spark plugs with new Tempest ones.

My old champions were crap. I ran the resistance test on them and they were anywhere between 0 and 20k ohms. Anyway, while in there, I also boroscoped by cylinders

here is a sample of how my exhaust valves look like.

I almost always fly my IO-360 lean of peak. Pretty much 90% of the time except when taking off :)

The burnt pizza look is fine but any deposit on the exhaust valve indicates, you could actually run leaner. I am a firm believer of lean of peak flying and even more now, after I’ve boroscoped my cylinders.