Hello. I need to extend about 3m OAT wire from CGR-30P

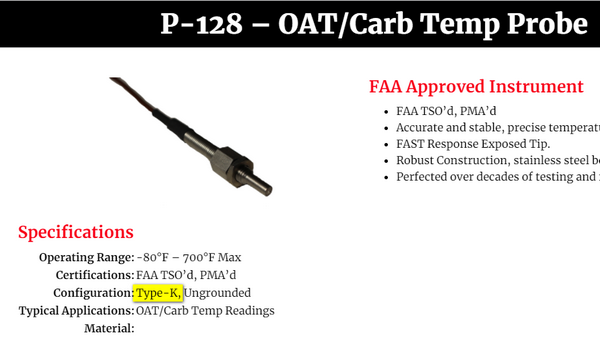

https://iflyei.com/product/p-128-oat-carb-temp-probe/

Unfortunatelly Im in Germany and to get this wire from US will cost more that wire itself.

Does anyone have idea what wire from EU market I can use to extend it? It’s thermocouple wire but ei is not giving specification of course…

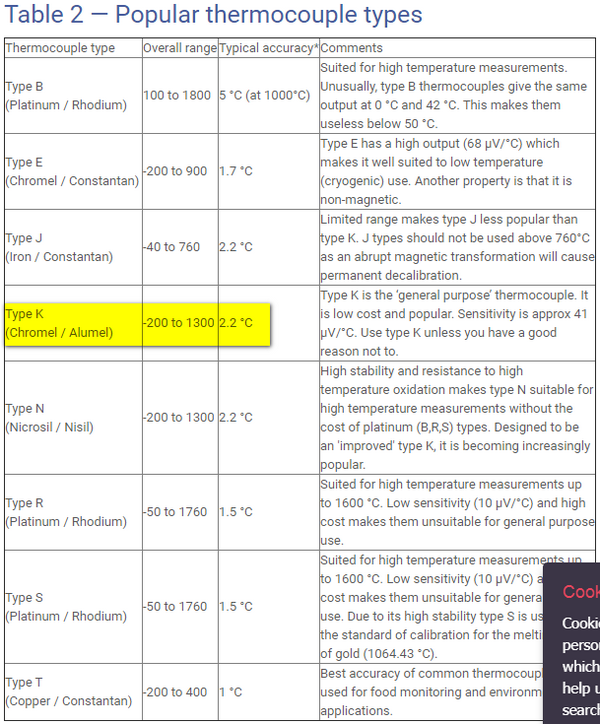

Type K – common as muck and just as cheap, as they say here

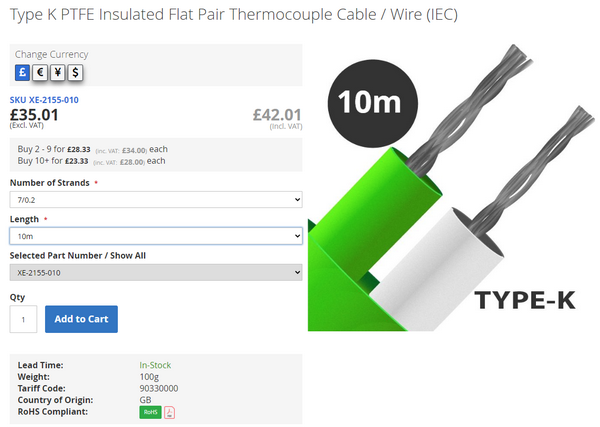

For aviation you don’t want PVC so this is perhaps the list.

and here is PTFE Type K wire.

£42 for 10m

You will need to crimp any joints – the material is not IME solderable although there may well be some solders. The eventual termination at the instrument has to be cold junction compensated as is normal with thermocouples.

However, it is absolutely terrible to use a thermocouple to measure OAT. The accuracy will be about 2C if you are lucky, unless you specially calibrate it. From here

2C accuracy is no good for aviation use because -1C will give you ice but +1C won’t. It would be OK for carburettor ice detection though.

If this firm can’t do cheap airmail to Germany, I can buy it for you  Thermocouples is my day job right now.

Thermocouples is my day job right now.

For OAT however I would use a PT100 (Class A accuracy 0.15C). The AD590 sensor commonly used in GA is not much better actually (nobody uses the “M” grade) but is fairly easy to tweak.

Germany has Ebay also.

If you want to spend money on thermocouple wire, go for Type B – €1000/m or so

Hi. Thank you, indeed its K. I will look at my suppliers. This is CGR-30 system from EI – I would use also other sensor for that…. but what to do..

Peter wrote:

You will need to crimp any joints – the material is not IME solderable although there may well be some solders.

To minimise the error, it’s recommended to weld them. The two materials in type K have very close melting points, around 1400°C. A butane micro-torch with a sharp flame should suffice. Another convenient method is capacitor discharge.

You can’t solder them. I saw soldered by solder sleeve splices EDM was showing 100*C OAT when splice was getting warm :)

I use mechanical splices – duraseal’s.

Exactly my point, any kind of solder will cause these errors. Crimping will cause them too, though to a lesser degree. The best solution is to twist the two wires together, then heat the tip until it melts into a tiny droplet.

Actually, when making a joint, you are welding two identical metals. It is only at the tip that you are welding two dissimilar metals.

I once had to make an extension cable for all the thermocouples going to an EDM700, and I used crimp high grade (Positronic) pins in a DB25. It’s been working for years. It does rely on the connector pair being all at the same temperature, which it should be.