They must have measured it very carefully. Most avionics work I have seen was done in-situ. When I did avionics harnesses I measured them up and did them on the bench (like yours) but if one gets it wrong then it’s a lot of work wasted.

On the bench, it is faster because you have good access to everything.

For now, despite that sometimes communications slows down, and even my request for information are not attending as I would like (taking into consideration the amount of money involved and other options as I read the manuals, like the AOA), it looks very professional.

But client orientation, irrespective the final quality of the product, seems to be a rare commodity.

One example, before I made my mind where to go, I have contacted a few other companies. Few answered, and when requested for clarifications, it would take endless time.

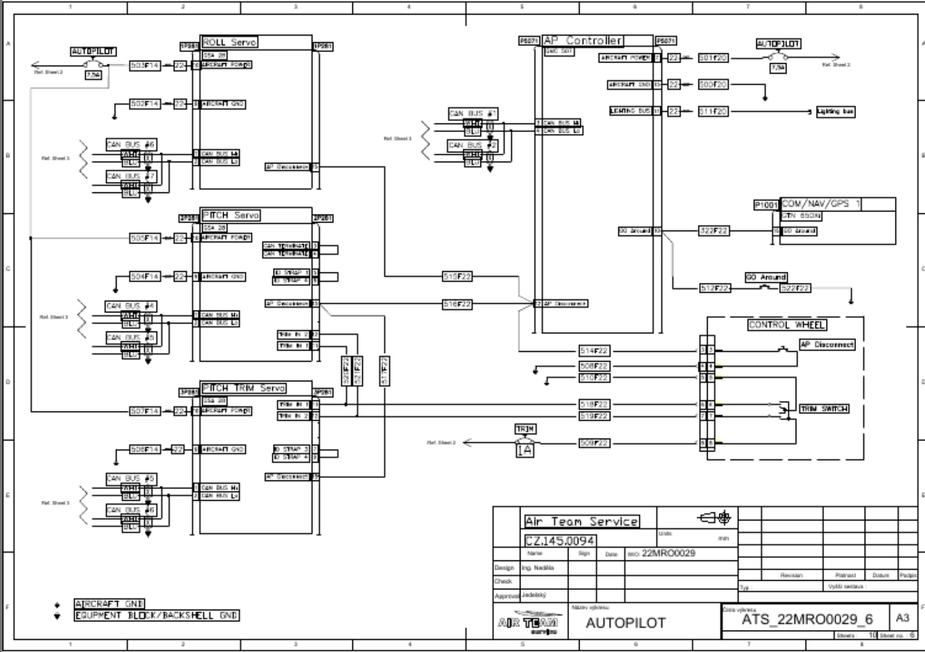

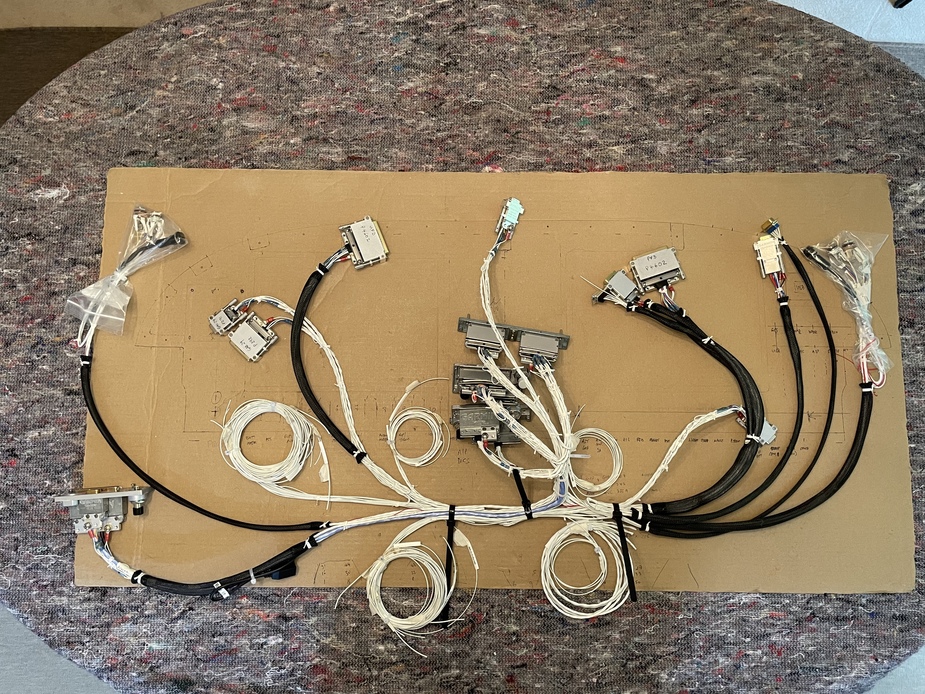

I’ve just completed this harness for a homebuilt RV9A.

Nice and clean

@wigglyamp beautiful work!

Yes; it is a lot easier when the runs are short e.g. all behind a panel. You can measure them up easily, and add a bit just in case. This is one of mine

despite that sometimes communications slows down, and even my request for information are not attending as I would like

That’s how the business has always been, and it’s got worse during what I would call the “CV19 driven scramble for everything”, which is why I would not use a shop which is too far away to visit, otherwise the result is likely to be like this.

Of course there are 2 sides to every story; a lot of customers are “difficult”, and bring planes which have 100 years’ worth of bodges in them

Nice, but DIY never worked for me  not even at home, now imagine on a flying machine!

not even at home, now imagine on a flying machine!

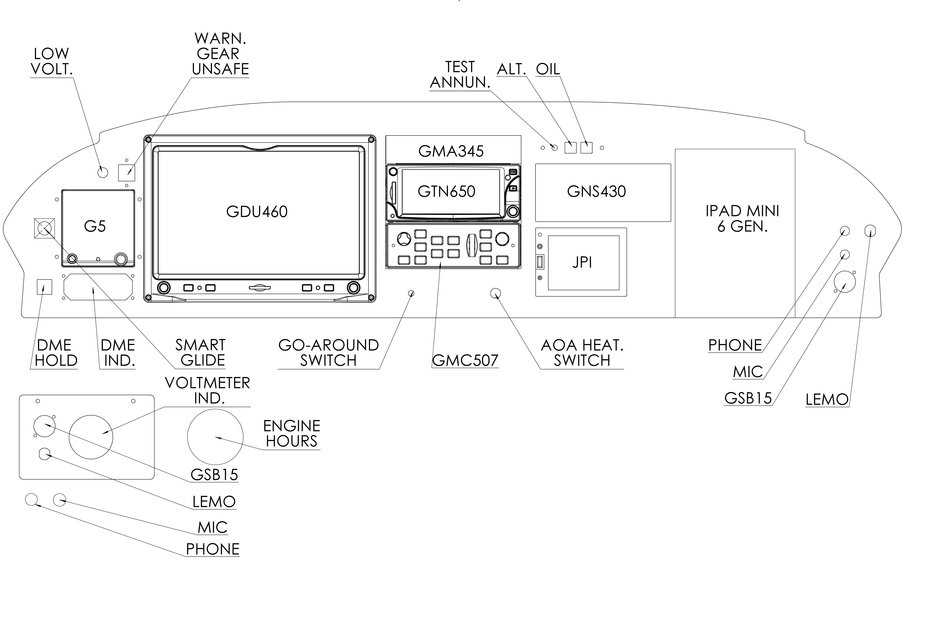

Last design proposal, and I am most happy with that. Ideas?

lmsl1967 wrote:

Ideas?

(inverted or gyro) 1G coffee holder?

lmsl1967 wrote:

Last design proposal, and I am most happy with that. Ideas?

I would put the DME indicator below the GMC507 and the DME Hold switch as close to it as possible – the AOA heating switch could be put somewhere else. If you’re flying Preferably, I would lower the GMC507 and put the DME stuff between it and the GTN, but in that case you might not have space for the TOGA button which really has to be where you have placed it.