I didn’t go through any real exercise of looking at options, no. I doubt I would have spent 200k upgrading the TB20 (if I had 200k to spend and there was something one could spend it on) but this upgrade was reasonable because

JasonC basically took the question ut of my mouth. What you’re saying is the right way to do it and makes total sense, it’s just that I would probably not have resisted the lure of an upgrade in the face of all those costs…

I’m glad your’e more sensible than me.

I don’t think the cost is excessive, looking at prices paid for some TB20s in a very good condition and with good equipment AND then you are still buying a potential can of worms. So a large factor is how much you value aircraft availability and reliability. If you fly say 150hrs a year and go places with it, these become important.

The installation downtime of 2 months was mostly with heavy rain banging on the hangar roof, almost every day. Most satisfying

Not sure if there is any more interest in this topic so this is just a quick update. Today was the first post-TKS flight and it doesn’t look like there is any performance loss, in cruise or rate of climb. Stall behaviour is slightly modified in that if you go deep into the buffet zone it eventually does a fairly rapid break which I don’t think it did before. But the speeds for stall warner onset and buffet onsets (both clean and full flaps) are not different.

Sounds like the care and time has paid off vs a quick and dirty install.

Peter wrote:

Not sure if there is any more interest in this topic

Yes there is !

I was seriously waiting for your first flight, and was eager to learn about eventual performance loss. This is a really good news !

After such a big work, I hope you didn’t discover any discrepancy in-flight…

I join Jason in that you deserved a good result, after all the work you performed. Sincere congrats !

I hope you’ll let us know about the behavior in icing conditions… before the temperature rises too much.

The fuel totaliser transducer turned out to be dead when we started up. I am not sure when it failed but it didn’t get noticed until takeoff (reading 0.0) so we aborted the takeoff, because it could be some huge fuel leak etc etc. Luckily I have a simulator box (described here) which generates 29.5 USG/hr so isolated it down to the sensor pretty quickly. I would not do a long trip without the totaliser but “the Alps” etc is OK. New one is in order – $300 last time one failed (2015).

This meant the engine operating point had to be set according to the EDM700 (peak EGT is about 12 GPH, and I normally fly 11.5 GPH at low level) and I was readily getting 140kt which is at the top end of what I ever saw before! To slow the plane down to the more usual 138kt I had to go quite a long way LOP.

So it doesn’t look like I am getting anything like the 5kt-7kt loss which most others have reported.

The only difference I noticed is that when you push the plane deep into the buffet it does eventually do quite an interesting break, which I think it didn’t do before. You would need to be completely asleep to get this far however.

Clean

Stall warner 75kt

Buffet onset 68kt

Full flap

Stall warner 60kt

Buffet onset 55kt

We were loaded as follows (MTOW 1400kg)

Peter wrote:

So it doesn’t look like I am getting anything like the 5kt-7kt loss which most others have reported.

In the one Columbia 400 I flew before and after, the loss was 2-3kt, basically 210kt cruise before and 207-208kt cruise after at FL180, in similar temperatures. That installation was well done, too; but the panels themselves weren’t designed to be as flush as they are in your case on the TB, so I was pleasantly surprised.

2-3 knots of TAS at FL180 should be 1.5 kt IAS.

And this is a slick / laminar flow wing !!

7kts IAS appears to be enormous !

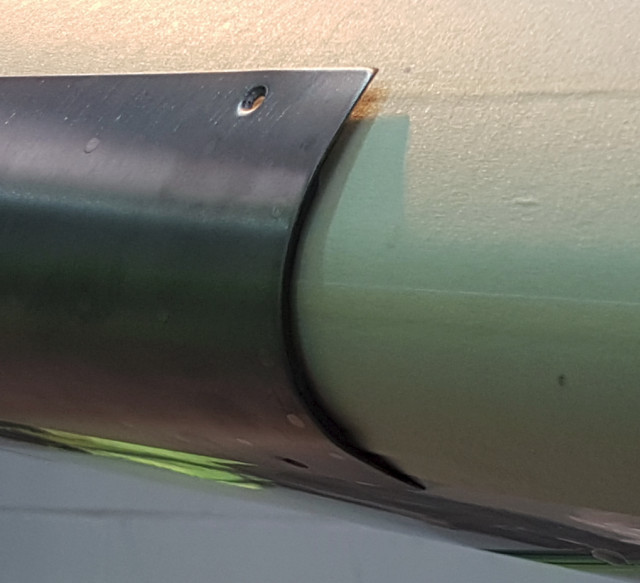

The TB panels were not flush

so needed a lot of forming, with a wooden clamp we constructed. It took me 1-2 days to do just that part, on the 8 panels (the 9th is the VS panel which fitted as it came).

Yes a loss of 7kt (IAS or TAS) is a great deal of engine HP going down the drain somewhere…

The high altitude performance is something that will be interesting. I have lots of experience of that in the TB20, up to FL210.