My PPL started in really shagged Tomahawks, whose floor would be soaked in water after a rainy night and it smelt like a public telephone box where people go for a pee. The yoke was bare metal (the plastic came off decades earlier), rusty from the sweat of hundreds of students.

On preflight, it was fairly normal to drain out several jars of pure water. This would confuse almost everybody because the blue tint of avgas is rather subtle. It confused me, but the instructor knew about this.

I am sure it was shagged filler cap seals. I change mine every 1-2 years – they cost about 20 quid for the two.

The same company, BTW, had an AOC for charter – google G-OMAR for one example of the UK PPL training industry

I have never drained any water from my TB20, in the 13 years I have had it. Not even a single drop. Over that time, that proves that condensation cannot be a major factor.

Well, more accurately, it proves that condensation on the ground does not find its way to the sampling drains

When I drained out and dumped the remaining ~30 USG after an “eventful” flight from southern Europe in 2014 (after which the fuel servo and other bits were changed as a precaution) I had the fuel lab-tested, and apart from the gum content being 10x out of spec (suggesting the bowser was standing around for months, without being sealed to the air) they found water in the bottom; clearly visible droplets.

This water must have either come from the bowser and did not reach the drains even 3 days later (I absolutely 100% checked them), or it materialised during the flight (-15C or so, mostly, and a large portion in +1C and lots of rain).

My feeling is that the drains are of limited value, and will work only for loads of water.

Nowadays I put in ~0.5% IPA, to help soak up some water.

Settling time of small water droplets can be very slow.

That is true, but I don’t see how you get 20 micron water droplets in the tank in the first place? A low pressure fuel pump will give maybe 2-300 micron size, at worst maybe 100 micron.

The water will be at the lowest point, not the fuel!

Yes indeed. Thanks.

You should sample fuel before moving the a/c

Agreed; it has had the max time to pool.

Actually I am not so sure about that. For the reason you invoke wrt the way the tanks are built , I believe that you would be better off shaking the wings somewhat to free drops that could have accumulated in various places which would subsequently fall to the lowest point.

Going back to my fuel sampler example, no matter how hard you shake the fuel/water mixture, the water is so much heavier than fuel that it will immediately fall to the bottom.

I rarely hangar or leave the aircraft with full tanks and never see any water. Water in the tanks is about filler cap seals not condensation.

My 172 allways stays out with full or empty tanks of Mogas (which attracts water more easily). Never seen more than 1 c.c. of water after draining or straining.And never the engine sputtered.

I found 1 litre of water though when I bought Mogas from some “guys” in south Italy and I had to abort my take-off !

NIL: 2cc ??? that’s nothing ! Wait til you pull 20cc …

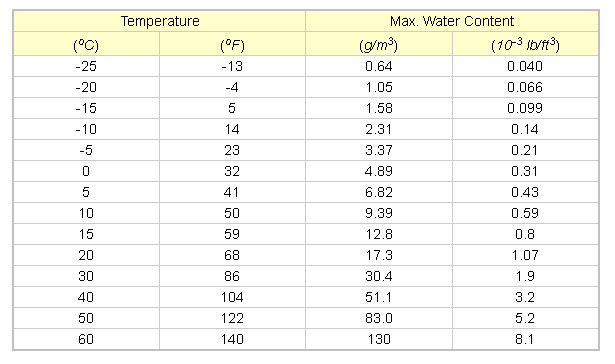

The problem with the condensation theory is that the air volume is fixed and there is only so much water which that volume of air can hold at a given temp/DP combination.

And there is no obvious mechanism for substantially or completely replacing the air in the tank with fresh humid air so it can re-condense over and over again. Both air and water vapour will flow through the tank vent(s) according to the law of partial pressures i.e. if the QNH changes from say 970 to say 1040 without the DP changing then the mass of water in vapour form inside the tank will go up by just 7%.

So to get a gradual buildup of water you would need the best (worst) conditions to keep repeating, in just the right way. I don’t think this happens in the real world, otherwise every non-sealed container on the earth would gradually become full of water

Anyway, a bit of googling digs out a few leads for those who want to dig further

Somebody could track down the Cessna data referred to. The author of that piece is rather well known!

A bit more googling…. From here and assuming the highest ambient on the earth at which you can get 100% RH as +40C (tropical rain?)

you are looking at 51cc per cubic meter, which for a TB20 tank is only 8.5cc! And that assumes the temp then drops to a low value so all that vapour condenses. So unless I missed something, that’s the upper limit.

So, obviously water can condense from the air, but you aren’t going to get a litre that way.

Another fairly obvious factor is that if you start with an empty tank, full of very humid air, but no actual condensation, and then you fill it up with fuel, all of that air will escape through the filler cap, together with the water vapour!

What is wrong with the above reasoning?

I will leave it to a chemist to work out how much IPA is needed in the tank to enable that 8.5cc to dissolve

My own opinion is that the condensation thing is a myth or so insignificant as to be not a factor, the fuel tank caps on piper aircraft are known to leak water if the seals are in poor condition.

That only leaves the fuelling installations, it is not uncommon to pick up a little water with AVGAS and I am sure that the water that I occasional find in my aircraft has come in with the fuel that has been uplifted.

JetA1 is another matter, the suff holds a lot more water and the fuel installations move a lot more volume, so there is a lot more scope for contamination ………. I once drained three and a half dusbin’s (60 USG ) of water from the inboard tank of a B747 during a routine maintenance check !

I would be very mindful of the water drains when flying diesel engined aircraft.

At this point I should also mention the problems of microbiological contamination that lives in the water at the bottom of the tank and feeds on the fuel, this has a corrosive effect on metal, as the fuel tanks on Diamond aircraft are metal it would seem to be other good reason to check the water drains regularly.

On a US forum there is a similar discussion. I posted the photo in message #1. An ex. USAAF Tanker pilot came back and said that the fuel you had was a ‘residential water’ rather then ’residual water as the older the water the yellow they become, hence the water that your friend drained were not the rain that you flew through but water that moved slowly to the drain point.

Ben

USAAF Tanker pilot came back and said that the fuel you had was a ‘residential water’ rather then ’residual water as the older the water the yellow they become, hence the water that your friend drained were not the rain that you flew through but water that moved slowly to the drain point.

In my opinion this only strengthens the fuel truck/fuel pump as the source of the water. The “residential water” (what a meaningless expression, condensed and trapped water?) has to come from somewhere other than the fuel tank of the airplane.