What is that?

BeechBaby wrote:

I am about to take legal action against one of them, not for financial recompense, to put the clod in jail

I just saw this post, and I know it’s years old, but how did the legal action go?

Unless you are in a very specialist area there is very little money to be made in GA maintenance and this is reflected in the wages paid to staff.

EASA requires academic qualifications and an amount of effort to get a maintenance licence that are inappropriate for the maintenance of GA aircraft .

The above two facts result in a shortage of licensed GA maintainers , it is simply not worth the effort of meeting the issue requirements of the licence exam and the subsequent responsibility when for the same education and effort you can get a far better paid and less onerous job.

The consequences of this is there is no new blood coming into the industry and when the old gits like me die ( I don’t intend to retire) there will be no one to certify GA aircraft.

While none of what I say above the excuses shoddy work it does explain the pressures put into the certifying staff.

Peter wrote:

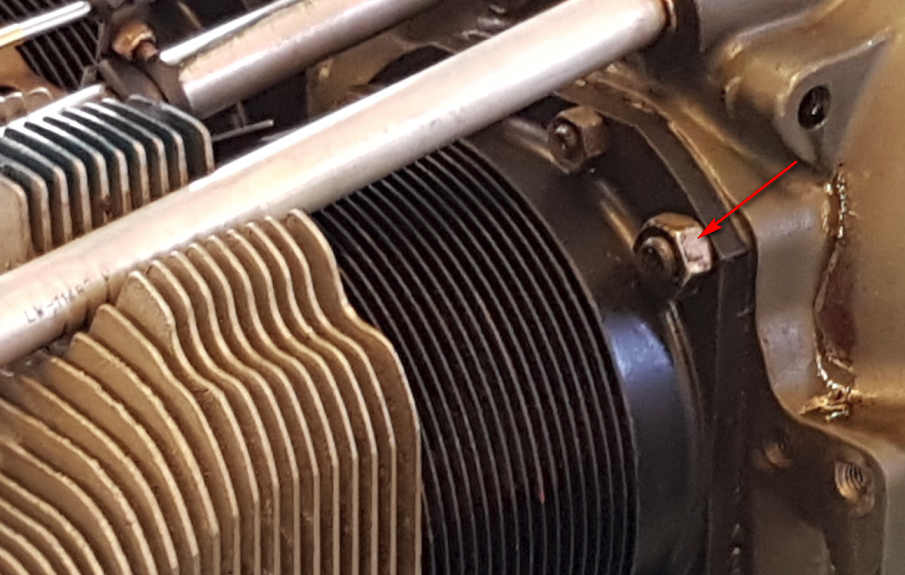

The rust on the broken surface

On the other hand that’s not exactly inspectable unless you’re in the habit of pulling all the cylinders every annual, which would clearly be excessive (Although I suspect in this case there may have been hints elsewhere of that corrosion, e.g. rust stains below the bolt).

Since the whole cross sectional area appears to be rusted, it appears that the nut etc fell off some time ago and wasn’t spotted.

That’ll happen even if the nut hasn’t fallen off. It’s one way you can tell if a crack has been propagating over an extended period of time – when finally fails, the fracture surfaces will show tarnishing/corrosion if it’s been a crack that’s been propagating slowly (they will be shiny if it happened quickly). If it had fallen off, that should have been picked up on preflight (not even annual) unless the plane is one of those with a cowling you can’t easily open.

A_and_C wrote:

Unless you are in a very specialist area there is very little money to be made in GA maintenance and this is reflected in the wages paid to staff.

Given the regulatory authorities deem it a necessary requirement in line with the manufacturers maintenance manual, (Annuals etc) and prohibit owner maintenance self programmes, then we have a bit of a predicament. Also most shops do not want the owner hovering about, rightly so.

A couple of years ago I thought I had found my maintenance nirvana. He explained he was very expensive, but very thorough.That was until I found an 8 inch wrench lodged under my engine block, left by him, and a large hole caused by corrosion due to a leaking hose. This had been there for a number of years. When questioned he ignored me, and refused to do any more work for me. What do you do?

BeechBaby wrote:

Also most shops do not want the owner hovering about, rightly so.

Wrongly so, IMHO. Very, incredibly wrongly so. Owner assisted maintenance (assuming an owner who has some mechanical aptitude) allows an owner to learn so much more and be much more pro-active about maintenance.

I’ll never use a shop that doesn’t let me work on my own aircraft (under their supervision where required). At present this is why I’ll never own a certified EASA reg plane.

A_and_C wrote:

Unless you are in a very specialist area there is very little money to be made in GA maintenance and this is reflected in the wages paid to staff.EASA requires academic qualifications and an amount of effort to get a maintenance licence that are inappropriate for the maintenance of GA aircraft .

The above two facts result in a shortage of licensed GA maintainers , it is simply not worth the effort of meeting the issue requirements of the licence exam and the subsequent responsibility when for the same education and effort you can get a far better paid and less onerous job.

The consequences of this is there is no new blood coming into the industry and when the old gits like me die ( I don’t intend to retire) there will be no one to certify GA aircraft.

While none of what I say above the excuses shoddy work it does explain the pressures put into the certifying staff.

It’s exactly the same problem here in the US. Newly minted A&P’s get recruited by big maintenance facilities/airliners where the straight out of the gate get health insurance, retirement fund, a nice union job and earn $60-90K+. And get to work in hangars where you can eat off the floor. Compared to a mum and pop shop that could barely pay you $50K, have no health insurance and probably crappy working conditions in filthy little shack somewhere. It’s a huge problem and I think we’ve only seen the very beginning of that shortage for GA.

I wanted to do the A&P myself so I could work on my plane, but it’s just time prohibitive to do so. You can do portions in night class and combine it with a job, but there’s a mandatory period you have to be in the shop and get the practical portion out, which just isn’t conducive to combining with any kind of regular job. This is why it’s really hard to do later in life unless you can take 2 years off.