The design is weird though in several ways.

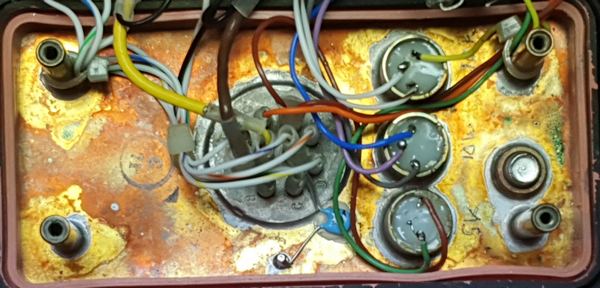

Why use such an elaborate box when o-ring sealed diecast cases have been available since for ever? This box must have cost a fortune to make, isn’t really sealed (due to poor design of the seal), and the trimpots they used aren’t o-ring sealed which is really stupid.

There are two of these in every Cessna piston twin. The new cost is around 30k each! Of course nobody actually pays this; it can be a sizeable % of the value of the whole plane  People buy them on US Ebay for about 2k and change them, usually off the books although on an N-reg it can be done legally. Somebody somewhere has the circuit diagram and is fixing them…

People buy them on US Ebay for about 2k and change them, usually off the books although on an N-reg it can be done legally. Somebody somewhere has the circuit diagram and is fixing them…

Peter wrote:

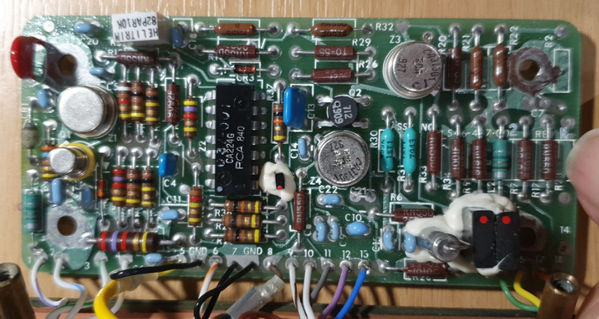

Finished repair

Impressive! Not sure I’d know where to begin…

Emir wrote:

Looks like electronics I used to make in 80s

That was pretty much the state of the art for homebrew electronics in the 1970s and early 1980s IIRC. I saved my BASIC and FORTRAN programs on paper tape in the late 1970s, and things really changed quickly up to and including the first Mac.

Peter wrote:

Like so much in GA electronics – designed by a muppet, and sold at an incredible price for 50 years.

Looks like electronics I used to make in 80s

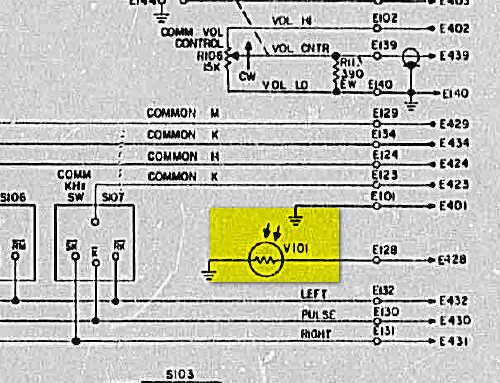

I have come across another one of these, P/N 360-926-001. Dates from late 1970s. It appears to be an interface for capacitive fuel sensors.

The “new” replacement is now GBP 28000 (not a typo).

Like the other 3 or 4 I have seen, just a duff trimpot (one of the three – 5k 10k 10k), prob99 due to water ingress.

The obvious way is to stick an 8mm mill down the hole, but even a carbide one is instantly destroyed because the cermet trimpots contain a ceramic disk  One has to put a 6mm drill bit down the hole from the outside (it gets wasted) and the trimpot gets more or less pushed out

One has to put a 6mm drill bit down the hole from the outside (it gets wasted) and the trimpot gets more or less pushed out

Finished repair

A special technique is needed to prevent the epoxy leaking downwards and out…

The construction is weird – a totally weird “waterproof” case which doesn’t really work anyway, and badly chosen trimpots. Like so much in GA electronics – designed by a muppet, and sold at an incredible price for 50 years. The “legal system” ensures the business is nicely protected.

1979 date code on one chip

That’s amazing – many thanks.

So I guess the main issue is having the MM.

If you know a friendly Part-145 company doing avionics repair and have the approriate maintenance docs for the device, then adding another type to the Part-145 capability list is a no-brainer. It’s not even necessary to declare repair capability – you can do an unapproved repair yourself and then have the Part-145 company inspect it and issue a Form 1 stating “inspected/tested” rather than “repaired”. Legalising unapproved repairs is within the remit of a Part-145 organisation if it is stated in its operations manual (so-called Maintenance Organisation Exposition).

So, no way to do this legally – in Europe at least.

alioth wrote:

Of course, this won’t be happening in Europe since 8.33 spacing obsoleted all these old radios

Obsolete does not mean worthless. We have some aircraft flying with one 8.33 kHz and one 25 kHz spacing radio. If a 25 kHz radio breaks and it really could be fixed cheaply, then we would certainly do that. (Well, perhaps not off the record.)

Peter wrote:

The big question is how to make it legal for re-installation.

I suspect you just do this sort of thing “off the books”. Of course, this won’t be happening in Europe since 8.33 spacing obsoleted all these old radios (although in newer radios, fixes to things that are not ASICs are also entirely possible by anyone with knowledge and an SMD rework station).

I wonder if there have been any changes recently on this, either under EASA (Part-ML / CS-STAN) or FAA.

On another site I came across a report of somebody trying to repair a KX155 radio, on which the fault appears to be just the photocell which controls the display brightness according to the ambient.

The MM for the KX155 is out there “in the wild”, and although the schematics in the copy I have are not complete it is pretty obvious how to fix this.

And a lot of faults in old avionics are easy to troubleshoot and fix. The more complex ones tend to be fixed by extracting PCBs from cannibalised avionics, as the past of least resistance.

The light dependent resistor (LDR) is under €1, or about €30 from “aviation suppliers”, but a “certified” repair is €1000+. As with so much in avionics, there are so many areas where a reasonably clever electronics engineer could repair a great deal of stuff.

The repair itself is of course legal. The big question is how to make it legal for re-installation.