I’ve updated the writeup with some component data. I also found the P/N of that little 16-bit accelerometer.

Possible correction (in case anyone cares, which I strongly doubt): the accelerometer found in another broken SG102 is definitely an ADXL321J which is only two-axis, so there must be another chip hiding somewhere. The diagnostic output absolutely shows three accelerometer axes and each can be tested by standing the unit on each of three faces.

I, for one, enjoy this thread and your detailed posts, Peter! I’m sure many more do.

I don’t understand much but so do I.

Ref: French electronics, in the late 70’s I was involving in sourcing components for the first ever TV video game. One chip was the 2708 EPROM (remember those?) and my favourite, as in most things chipwise, was National Semiconductor in Santa Clara. But Thomson CSF said they could do EPROMs more cheaply and my client liked the sound of that. So off I went to France with my engineer, to be entertained that evening by no less than the French Minister of Technology (or somesuch) at some incredibly lavish resturaunt in the hills with a picture window at which we were seated overlooking the lights of Grenoble. At some point in the evening he made a grand gesture out of the window: “Zis”, he said, “Is ze zilicon valley of Fronce!”.

Next morning we were taken to the factory where they appeared to be using 3" wafers, and were shown 2708’s on test. Of course the 2708 had a very convenient window in it (for UV erasing) and the lab we were in had an equally convenient microscope on the bench. Peering at the chip that they had ‘made’, it was instantly obvious that it was the National Semiconductor one. I said nothing.

If this sounds Francophobe, let me relate that my very first job in the electronics biz was working in the holiday in an MOD lab where they were making their own LED’s. They’d arranged a big demo for some big wigs higher up the military food chain and my job was to machine a neat little aluminium housing for their prototype 7-segment LED. Unfortunately they were having big trouble with the doping and and couldn’t get more than a faint glimmer out of the LED, so the day before the demo I was handed the sample HP chip that they were copying and told to install that instead. I signed the official secrets act over that so don’t tell anyone.

DEC used to write messages to the Soviets on their chips, as they knew the Soviets would clone their machines :-)

A friend of mine has been doing de-encapsulation of certain classic chips (Ferranti ULAs, Zilog Z80 etc) and transcribing the contents onto paper (for the Spectrum ULA, a 2m x 2m sheet, which was then converted to a logic block diagram). The Z80 had a few features to frustrate cloning by de-encapsulation and copying the die. I’d have to ask what exactly they were but if memory serves, it was things like P-channel transistors in unexpected places that would stop the chip from working unless you fully reverse engineered it and realised it wasn’t an N-channel FET — which would cost the cloner as much as designing a compatible chip from scratch.

Other amusing stories from back in the day that I heard – if you look at die pictures of the original 6502, there’s a small rectangular part of the die that has nothing on it. Apparently, when they were designing the chip (all by hand, on a huge sheet on the wall), there was a power socket in the way, so they just didn’t draw anything there.

Similarly, the Spectrum ULA was saved by a speck of dust. When Sinclair had designed the interconnect layer (on paper of course), they gave it to Ferranti, who digitised it and created the photo tools for making the chip, and fabricated the chip. The engineer who digitsed it made an error, and missed off connecting a clock signal from one half of the chip to the other. Of course, this was a huge problem because Sinclair ran everything on unrealistic deadlines, and there wasn’t time to hit the deadlines if testing had to be pushed back. Fortuitously, though, the only speck of dust in the clean room had landed in just the right place on the reticule (the photo tools to make the interconnect layer) to bridge the missing link in the clock circuit, so one die on the wafer actually worked, and they could test the chip and go into production on time!

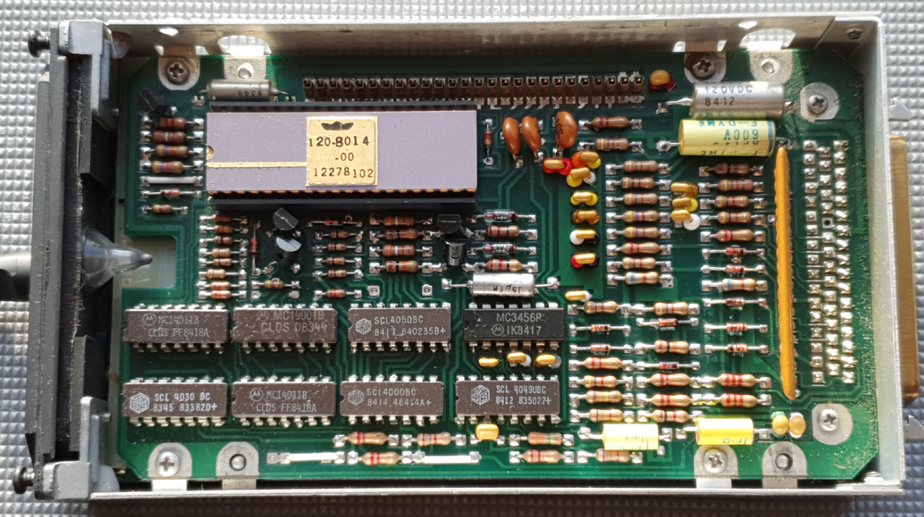

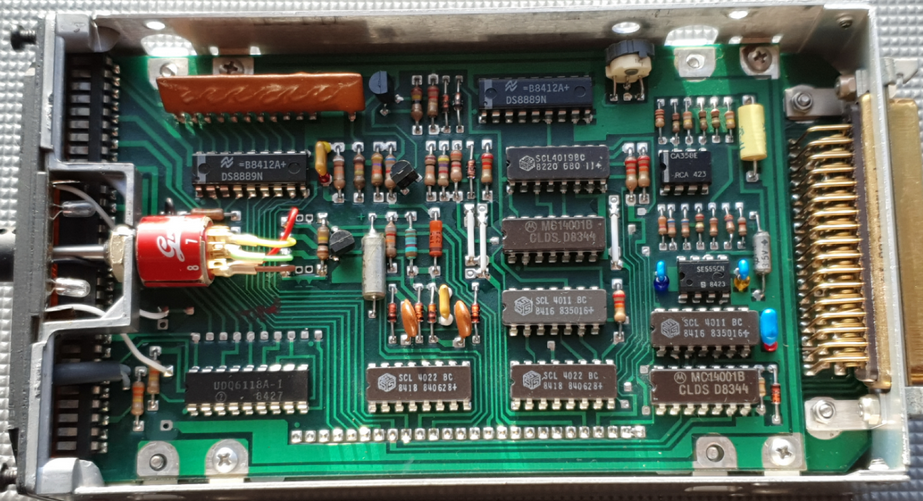

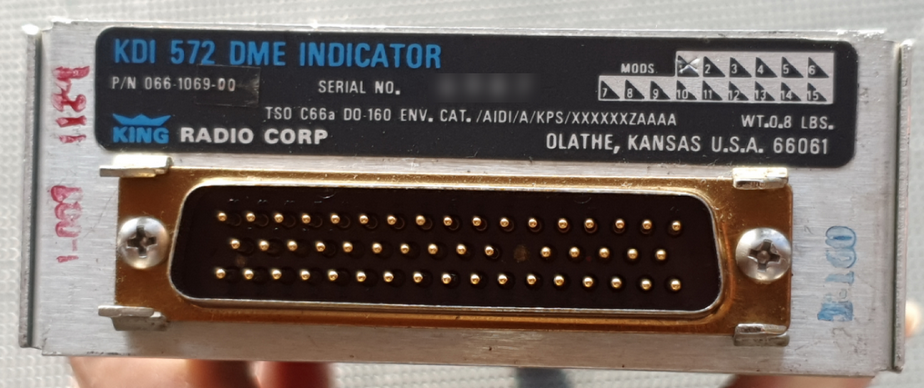

OK here goes another relic from a bygone age: a KDI572. I got it as a part of a package from the US. Of course I took it apart

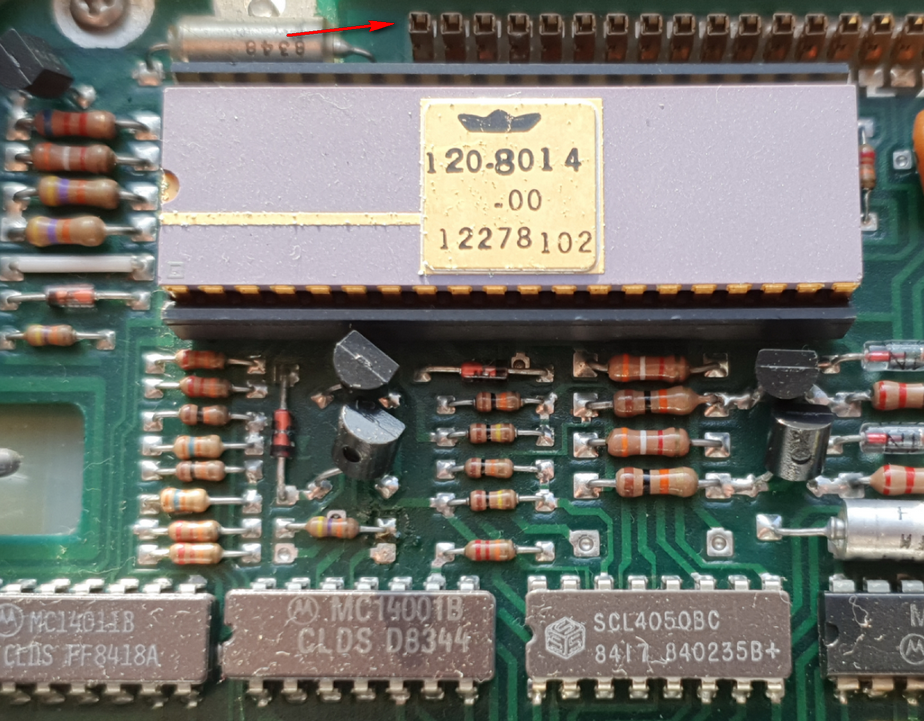

The big one, 120-8014-00, is some sort of custom chip, made for King. It lists here for $152, presumably used.

Date codes on chips are generally 1984

A high grade rotary switch

That missing pin was actually extracted and the hole filled with some resin

The single row connector at the top is probably a source of a lot of trouble over the years. The way the plastic TO92 cased transistors were inserted is also a bad (but very common) practice because it leaves the package under permanent stress. The correct way is to preform the leads before insertion into the PCB

and I think this one isn’t going to work; spot the crack in the display

The MMs for this stuff date back to 1979. I have them for the DMEs but don’t have one for the KDI572.

The getter in the back of the display still looks silvery, so perhaps the glass isn’t cracked all the way through? (Normally the getter turns dusty white once air has got in).

I had a closer look; the glass is smashed all the way through, with both front and back panes broken. Probably bad packaging.

The display is soldered to the PCB – it doesn’t use a connector like I believe some King products do – and changing it without damage would be very tricky.

I might put some low viscosity epoxy on it, anyway.

The King KNS80 display is on a connector (springy type, you probably know what I mean). Changing one out is trivial, but changing the whole unit even more so ;)