Not all Chinese companies are equal, some of them are putting out some really decent stuff now (even if there’s a lot of crap still being produced). We also used to underestimate the Japanese, too. If Cisco, Juniper et al. rest on their laurels, they might have a problem within 10 years.

Just watched the AoA sensor teardown; thanks for posting it @Off_Field.

They could certainly have made the position encoder more robust (avoided the slip rings) but apart from that the construction is probably really standard.

There is a lot more electronics involved in getting the AoA value. That resolver has to be energised and the output from it has to be demodulated. There is probably a whole PCB full of bits somewhere, and if that stops working, you lose the AoA function.

Not all Chinese companies are equal, some of them are putting out some really decent stuff now (even if there’s a lot of crap still being produced). We also used to underestimate the Japanese, too. If Cisco, Juniper et al. rest on their laurels, they might have a problem within 10 years.

Cisco have their own big problems with having got way too big. And there is a massive difference in culture and attitude between the Chinese and the Japanese. The Chinese seem to be trying to get rich quick and to hell with anything else. I’ve been dealing with firms there for 20+ years. The Japanese are self critical and want to continually improve, and they have done this from within, whereas the cases where the Chinese don’t make crap is mostly where a Western (or other e.g. Samsung) company has sent a load of their own people to live out there in the factory – as with phones etc. Japan is declining because they have done too well and got rich like the rest of us  A generalisation I know but I see no change over the 20 years. I am about to pull a product line out of China because of the frequency at which they suddenly vanish and we lose a load of tooling.

A generalisation I know but I see no change over the 20 years. I am about to pull a product line out of China because of the frequency at which they suddenly vanish and we lose a load of tooling.

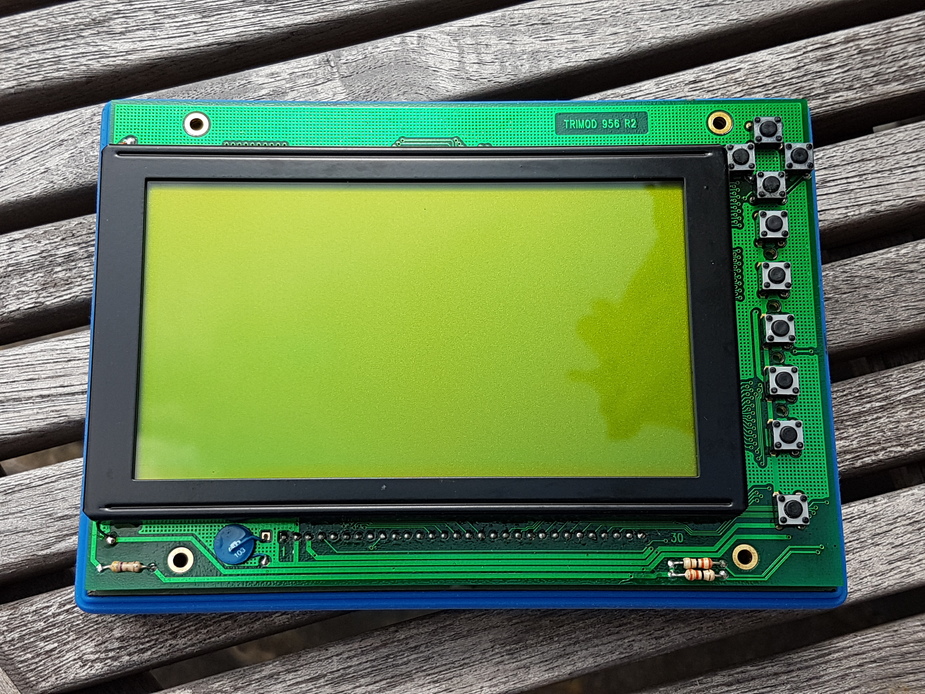

This is the Skyforce Skymap 2. This box was popular in the 1990s. Specification A colour version, the Skymap 3C, came later.

I bought one the day I passed the PPL skills test. It was about £500, just about usable for finding Le Touquet, but there wasn’t much else. With no keypad, waypoint entry was too painful but IIRC one could upload routes into it from Navbox.

I soon moved to tablets and proper moving maps and the Skymap ended up in the emergency bag, next to the life raft, and I put in new batteries every year… Eventually it was replaced with an ex Ebay Garmin 196 which I still have there.

Recently I picked up another Skymap 2 out of a dustbin in some avionics shop. Here are the internals. It was a tour de force of design back then, 25 years ago…

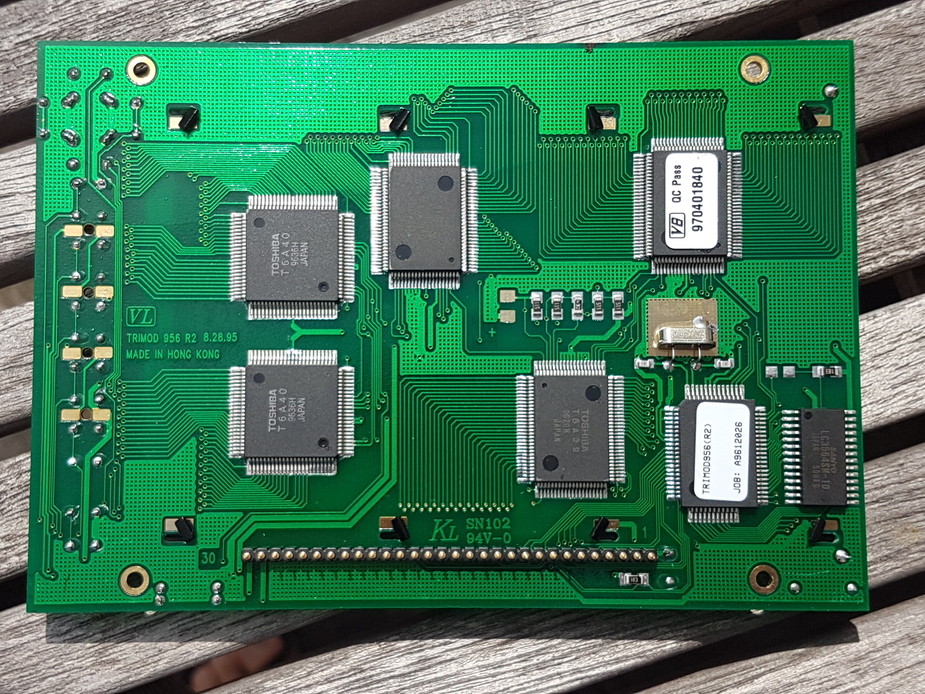

The monochrome LCD is an off the shelf item from Japan

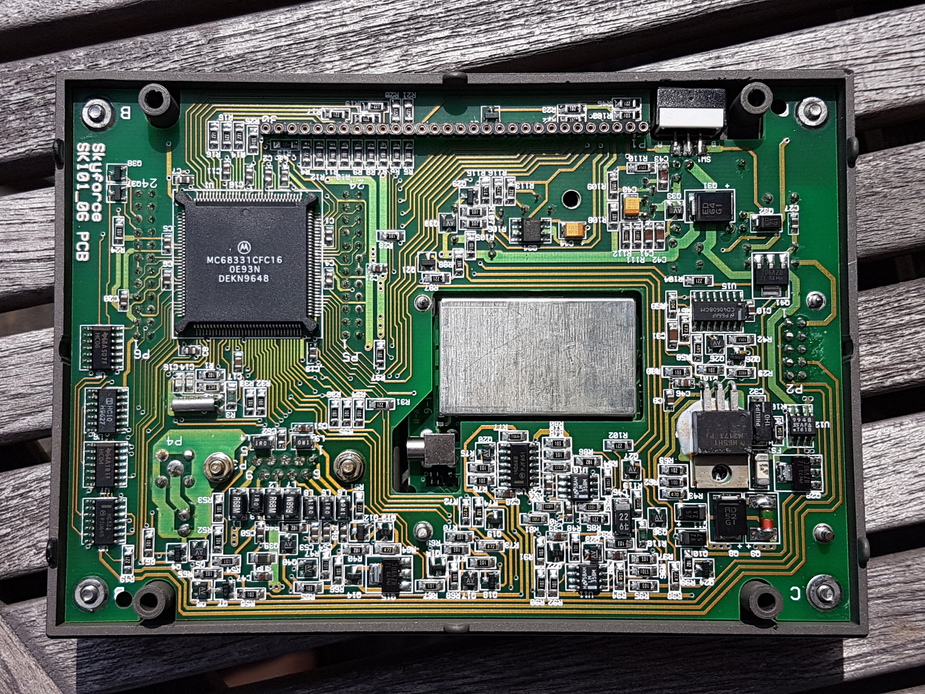

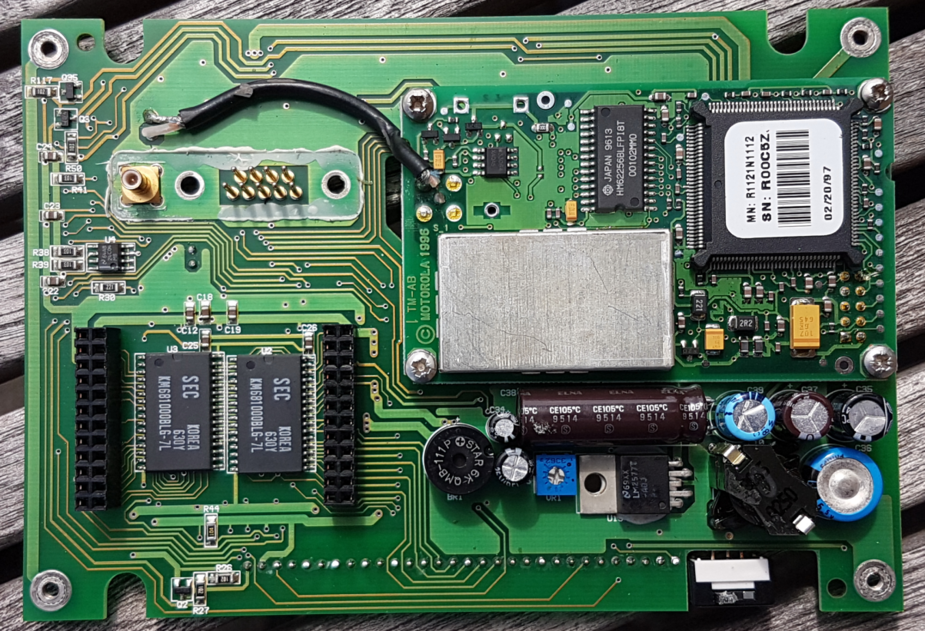

Main processor board. The 68331 is still manufactured, amazingly

The back of the processor board, with 128k x 16 SRAM. The extra PCB is the GPS module

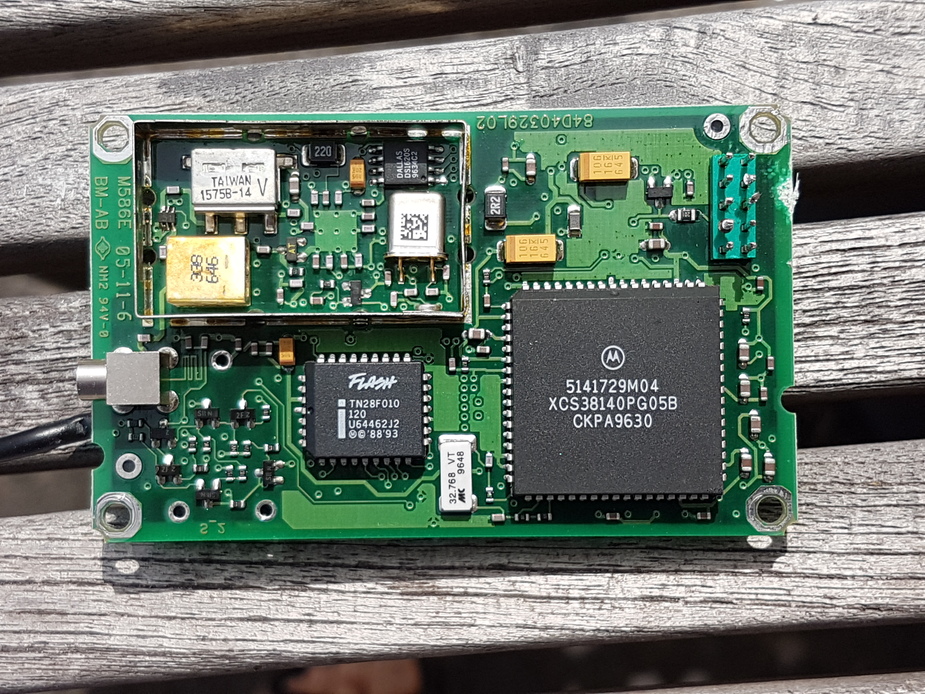

GPS module. XCS38140 is an unknown part, existing only with some old stock outlets, but I assume it is a processor because of the 128k x 8 Flash chip next to it

Back of the GPS module PCB. The huge chip is another 68331!

Honeywell later bought Skyforce and they did work on the KLN89, KLN94, the KMD150 (a panel mounted “certified” version of the Skymap 3C), and the KMD550 / 850 MFD of which many thousands were sold.

38140 is a GPS digital correlator designed to interoperate with the 68331. It was one of the first chips (if not the first) to support WAAS.

Don’t be too surprised about various microcontrollers/processors still in production. Really the only things that have properly fallen by the wayside are the ‘mainstream’ older x86 chips (the Garmin gpsmap 195 has an 80386sx ‘embedded version’ in it – no wonder it was a destroyer of batteries – although the 80286 lasted a surprisingly long time – I think the ’286 outlived the 486).

After all the Z80 and 6502 are still manufactured (and have been, continuously, since 1975 or so) in their 40 pin DIP versions, albeit in CMOS these days. So much industrial control stuff uses these chips, and the various Motorola processors, that they are still made and (in the case of the Z80 at least) you can buy them from Farnell. They are cheap and very well understood. The glue logic, too – all the 74 series and 4000 series stuff is still made, including the parts you may expect to be obscure. I had an analogue multiplexer fail in a vintage synthesiser I had, and could buy the replacement part brand new from Farnell.

Yes; that 68k CPU seems to be a popular part in the automotive sector.

A 20 year life seems common. At work we use a H8/332 which went on last time buy after about 25 years, and after that I bought a ton of them from US “cowboy” outlets at half the price we used to pay officially; presumably because once the LTB was announced, a lot of stockists quickly offloaded their stocks.

I doubt this will be the case in the future though. Atmel chip (AVR especially) life is measured in single digit years. I hope ST ARM is better since we are doing a new design with that, but 20 years’ time I will be in my 80s and watching my flying videos in a care home

I also wonder whether the long manufacturing life of the original chips is driven by the large number of whizz kids who learnt on them in the 1970s and who have not yet retired, 40 years later. When I was at univ, 1975-78, everybody was programming the Z80. Then the explosion in microprocessor use in the 1980s spread these chips everywhere. All my early designs used it, or derivatives (z180, z280). We still make a z180 based product. But if you take the present generation, they will not use any of these, even if the project doesn’t need any power. They will use an ARM, but the ARM sphere is divided into hundreds of different chips.

Peter wrote:

Compare the KMA20 with a KLN94

Very interesting thread. What’s the difference? One has fewer „mini batteries“ :) soldered to the bottom and more flat chips?

The KMA20 has a load of manually done wiring, components up in the air (those cylindrical items are capacitors), some crappy components used, very labour intensive, vulnerable to vibration, etc. The KLN94 is built using modern methods and is much more immune to vibration. It is probably comparing a 1970s low volume hand build (and with little investment, because that product looks really amateurish, with all those wires) with a 1990s production build.

With low cost CAD, pick and place machines etc. modern methods are also a lot cheaper – I had a small run of 100 boards done (4 layer PCB), with half a dozen ICs (a CPLD, flash memory, some RAM, ethernet IC, a handful of transistors and a lot of passives) done and it worked out at about £30 per board, almost fully assembled (the connectors which were through hole I soldered myself). The schematic and PCB layout software I used is open source.