IIRC, just a WAG : That looks similar to an gear and/or stall audio warning board I pulled out of a CEssna retract – I think the pot was for volume control.

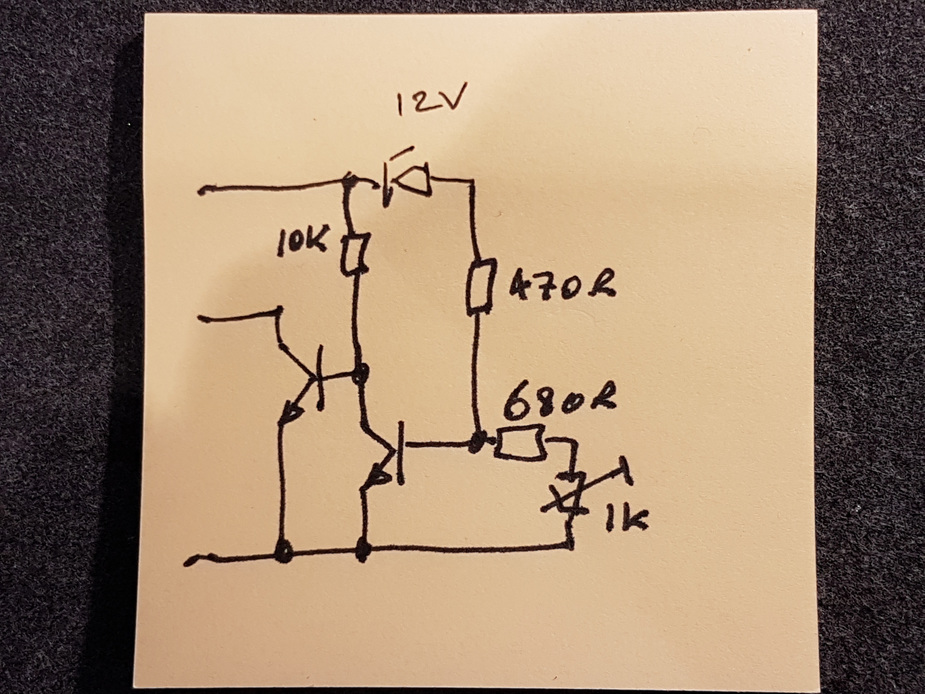

Looks like it serves to switch something on (or off) when the supply voltage passes a certain threshold; the threshold being adjustable with the trimpot. Apparently meant to be more or less universal, it can cater for different kind of loads (lamp, relay, buzzer) – with an inductive load, an inverse diode is required to protect the 2N1711 and the place is neatly provided, but unoccupied here.

The lack of cooling to the 2N17711 tells us it is meant to switch, either ON or OFF, but I would then have expected some kind of schmitt trigger for improved stability – easy to add as two transistors are present. It is really a simple design, not to say primitive. And the kind of trimpot used – open, ready to be disturbed by the least bit of dirt and/or vibration – doesn’t promise a high degree of reliability/stability, either. In fact it is surprising to see this contraption coming out of a certified plane – who can ever have certified it?

The 12V zener seems to indicate a 24V installation, is that correct for a TB10? In a 12V application it would be 5,6V or so.

With reference to the upper picture, the connections are clearly (lower) ground, (middle) switched output, (upper) supply.

I traced the circuit

The pot is currently set to about 200 ohms, so this is a threshold detector, whereby the 2N1711 is ON until the supply exceeds about 13V and then it turns OFF.

So, maybe an alternator fault detector in a 12V aircraft (whose bus voltage is 14V)?

It could even be a voltage regulator for an alternator but the 2N1711 could never carry the field current.

Yes – the use of an open pot in this application (humidity, vibration, etc) is really crap practice, but avionics is full of this sort of thing. Those Allen-Bradley ceramic-substrate pots were OK for a benign environment and were really popular in industrial electronics in the 1970s.

Peter wrote:

So, maybe an alternator fault detector in a 12V aircraft (whose bus voltage is 14V)?

That would be very well possible. At least Socata always had quite clever electrics, compared to Cessna or Piper for example. The avionics bus switching is a good example, using paint over well cleaned ground connections, are things that are non excistent Cessna and Piper of the same era.

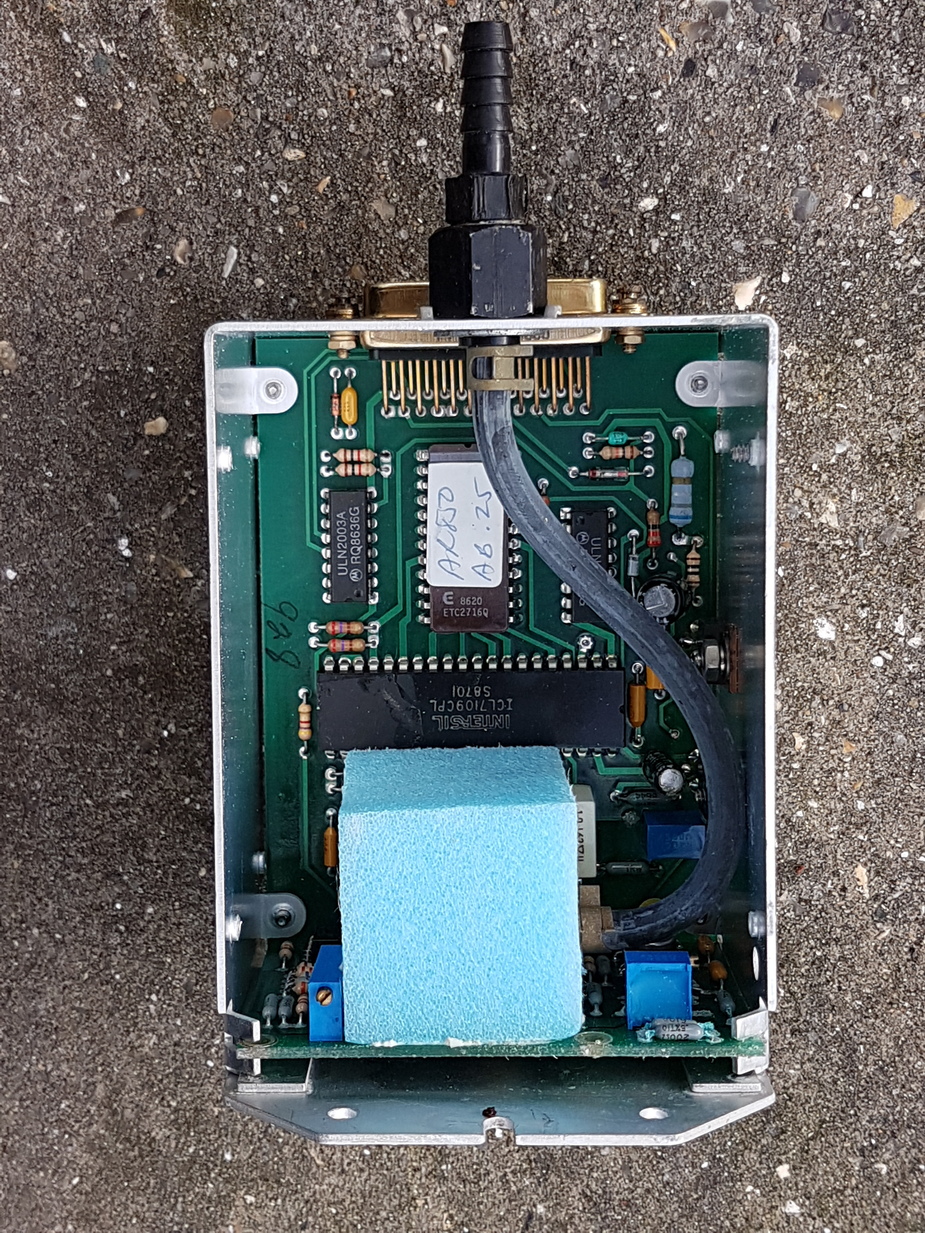

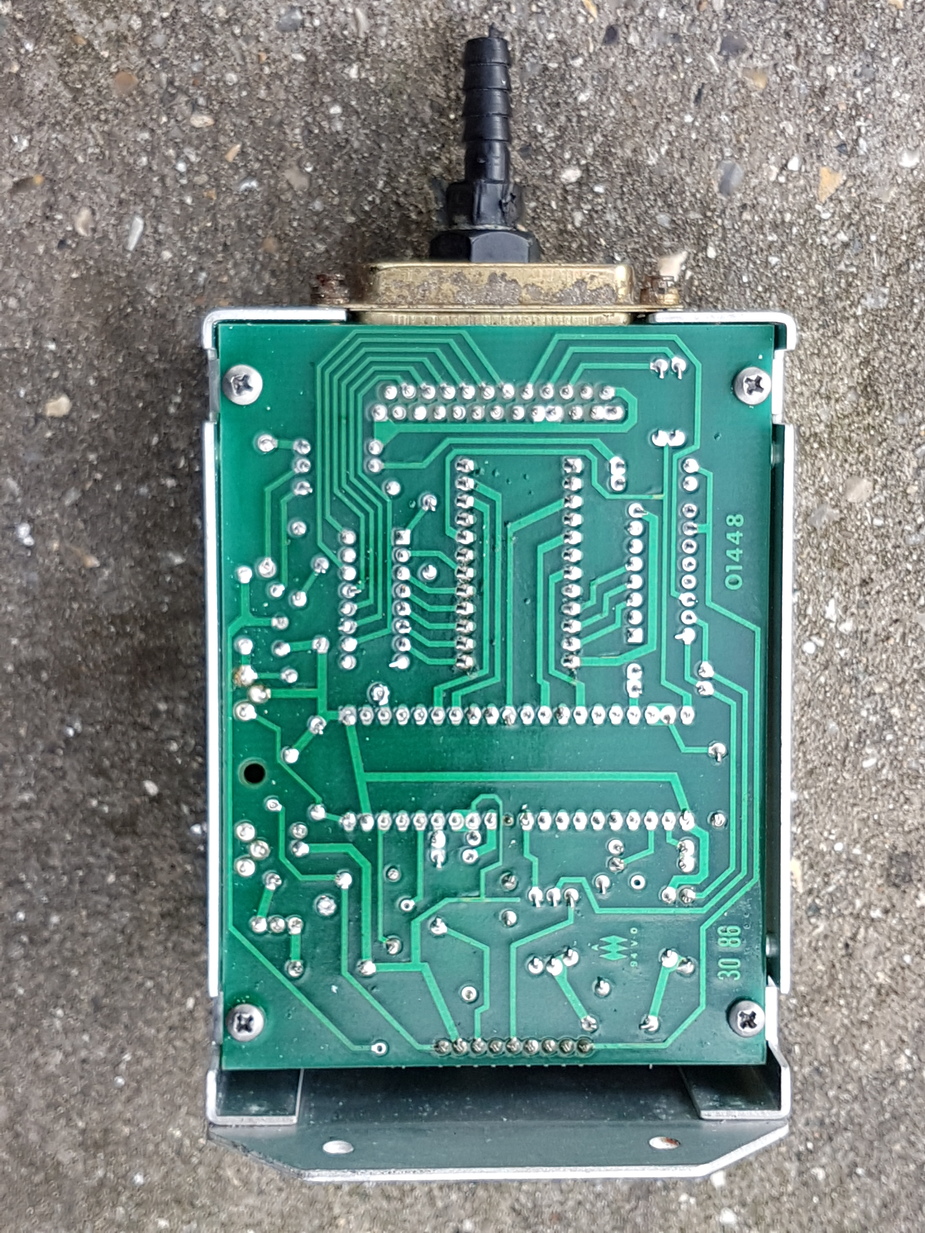

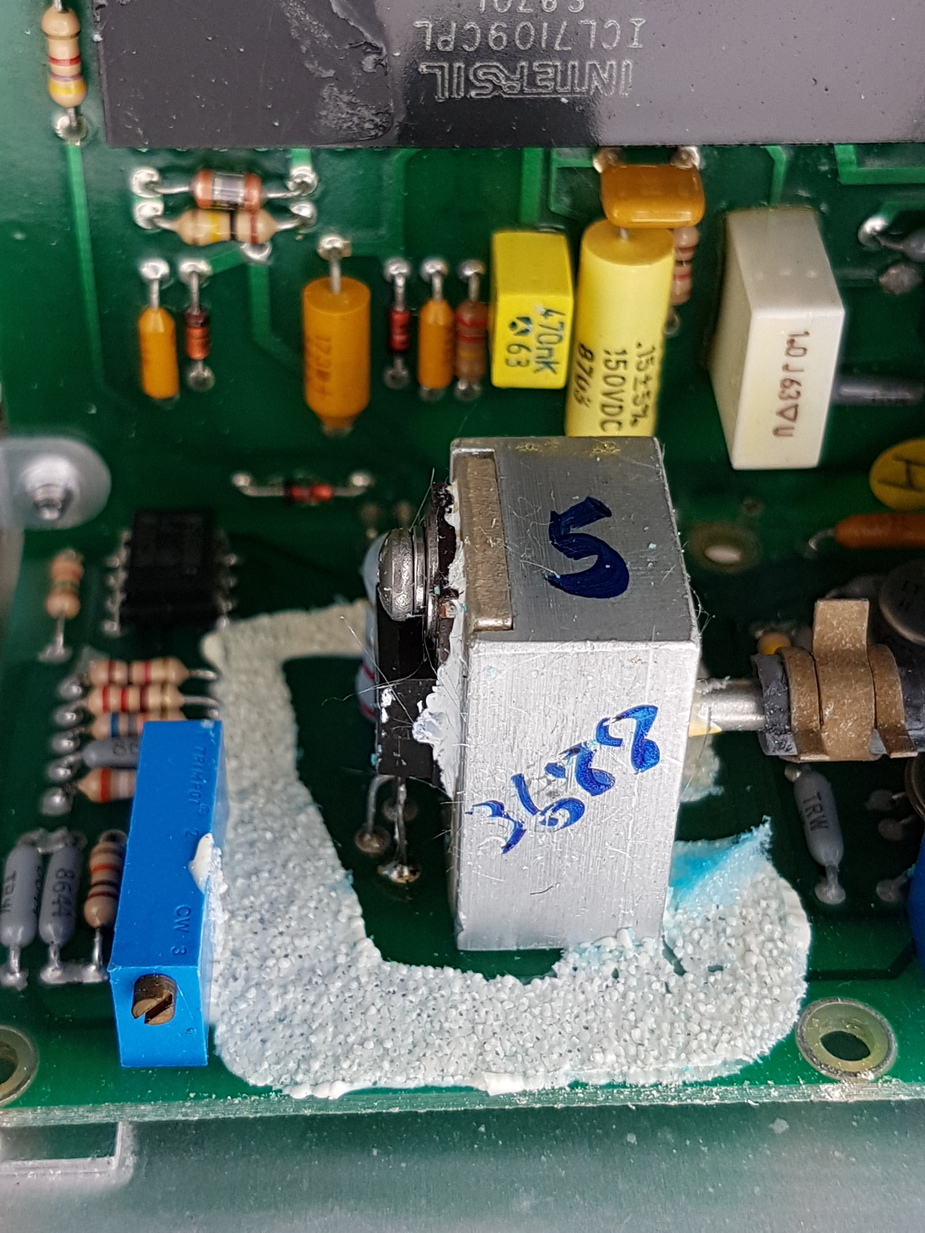

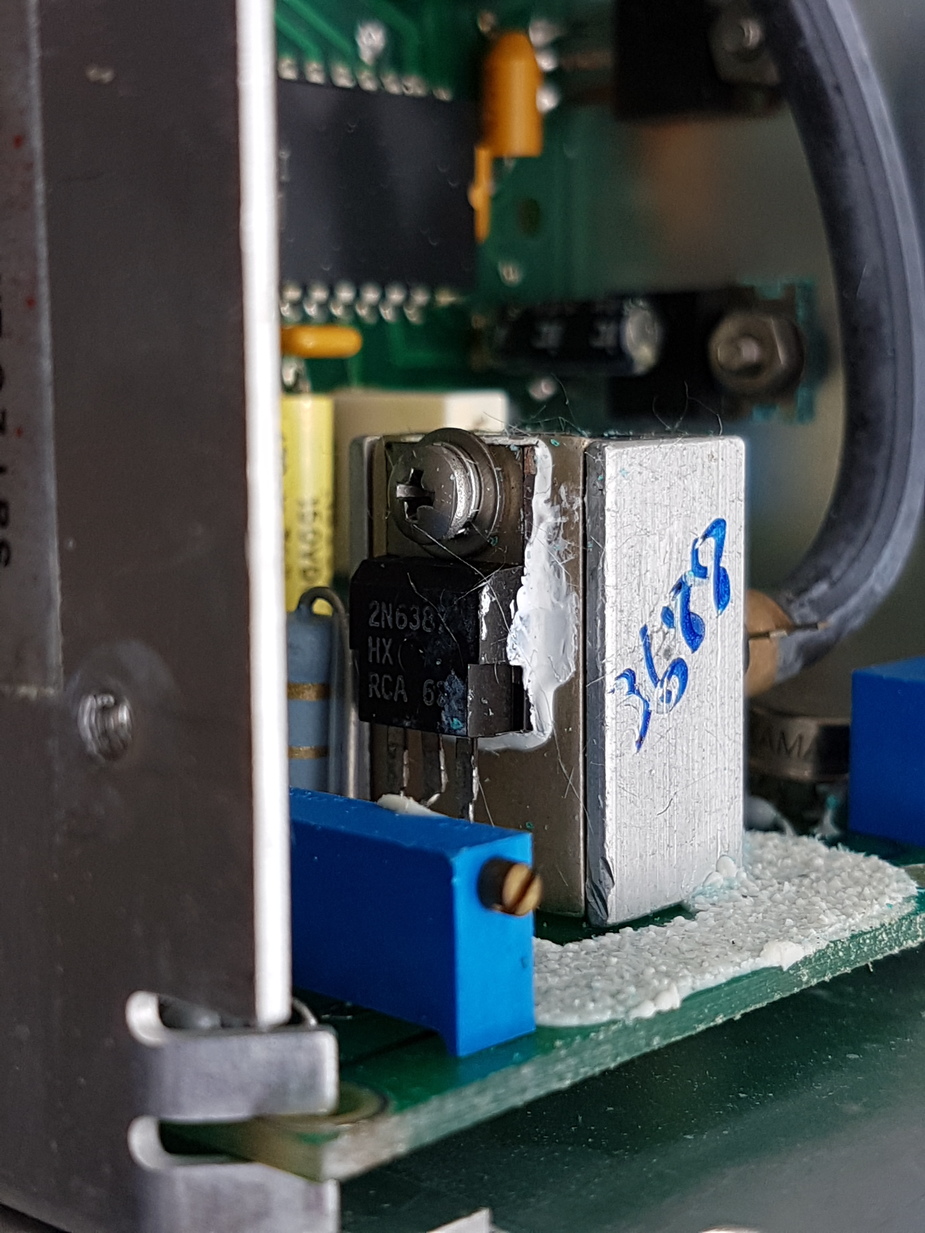

NARCO AR-850 altitude encoder.

Component date codes suggest it was made 1987. The ICL7109 is a 12-bit A-D converter and they appear to be using a 2716 EPROM to convert to Gray code, with a lookup table.

I can’t see the pressure sensor type.

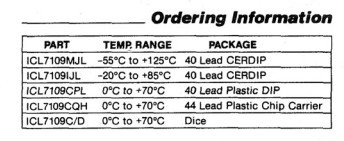

Oddly enough, while they chose the LT1008 op-amp very well (an amazing spec device in those days) including its temp range, the ICL7109CPL is not specced below 0C

Good old Narco and their TSO approvals

The pressure sensor appears to be heated by the 2N6307 power transistor, hence the big blue insulation block.

Total parts cost in 1987 would have been about $50 (100+ batch), plus whatever the pressure sensor cost.

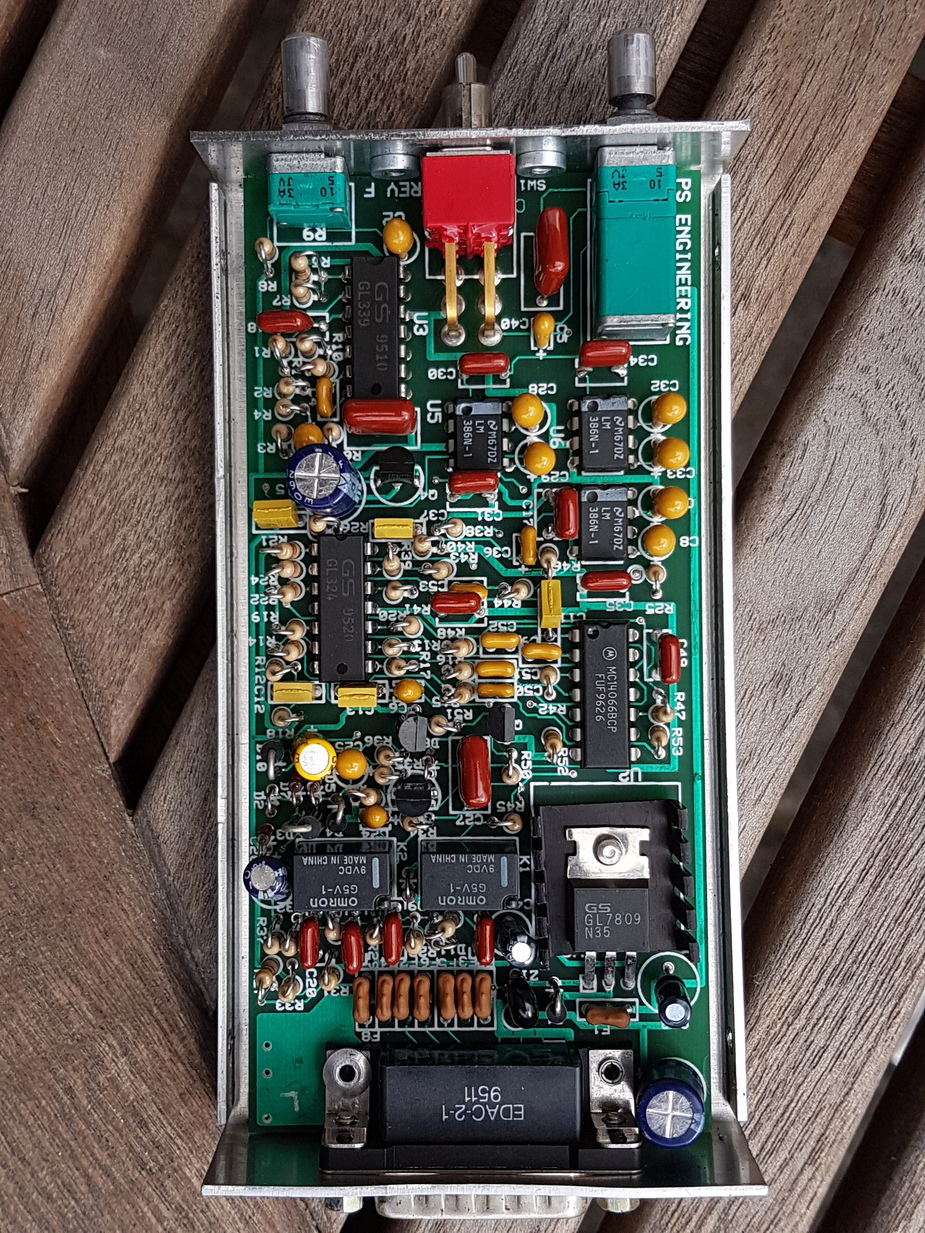

PS Engineering PM-501 intercom.

From component date codes, made around 1996. Might be a much older product since it doesn’t use surface mount parts.

The two pots are interesting. I wonder who makes them?

A quite well made product.

Parts cost maybe $50 (100+ batches).

This one may be working so if anybody wants it, they can have it for the cost of the postage.

the ICL7109CPL is not specced below 0C

Ah, a 7109. I remember it well. I’m not sure the 2716 is rated below 0C either. Maybe the 2N6307 put out sufficient heat to keep it all warm on a chilly day!! It does raise a reliability question though, for a unit rated -20C to +55C!!

This shows that avionics approvals mean nothing if the vendor wants to cheat, ot just makes a mistake. But choosing components with the right temp range is the most basic thing… This designer didn’t have a clue.

I used the slightly similar 7107 back in 1978 – in the 501D. Same era as the above avionics really

I don’t think that heating arrangement would have warmed up the internals much. Anyway is it possible to meet the TSO environmental requirements with a heater? I somehow doubt it, because it would be a fantastically easy solution to stuff like some autopilot components (servos) which need to work (in some airframes) down to -55C and there you are facing a poor choice of components. It is quite tricky to design a brushless version of say a King servo wholly with such components. Even buying the motor with the manufacturer specifying that temp range can be tough, which is probably why the King servos use the crappy Globe motors.

I read somewhere that a 737 has a heated gearbox for the rudder but somebody there would have had a lot more $$$ to throw at it.

Peter wrote:

I read somewhere that a 737 has a heated gearbox for the rudder

Isn’t the 737 rudder actuated by a hydraulic PCU?!

No idea – maybe @A_and_C knows; he has an engineer license (as well as a type rating) for all this stuff. It could be some other type.

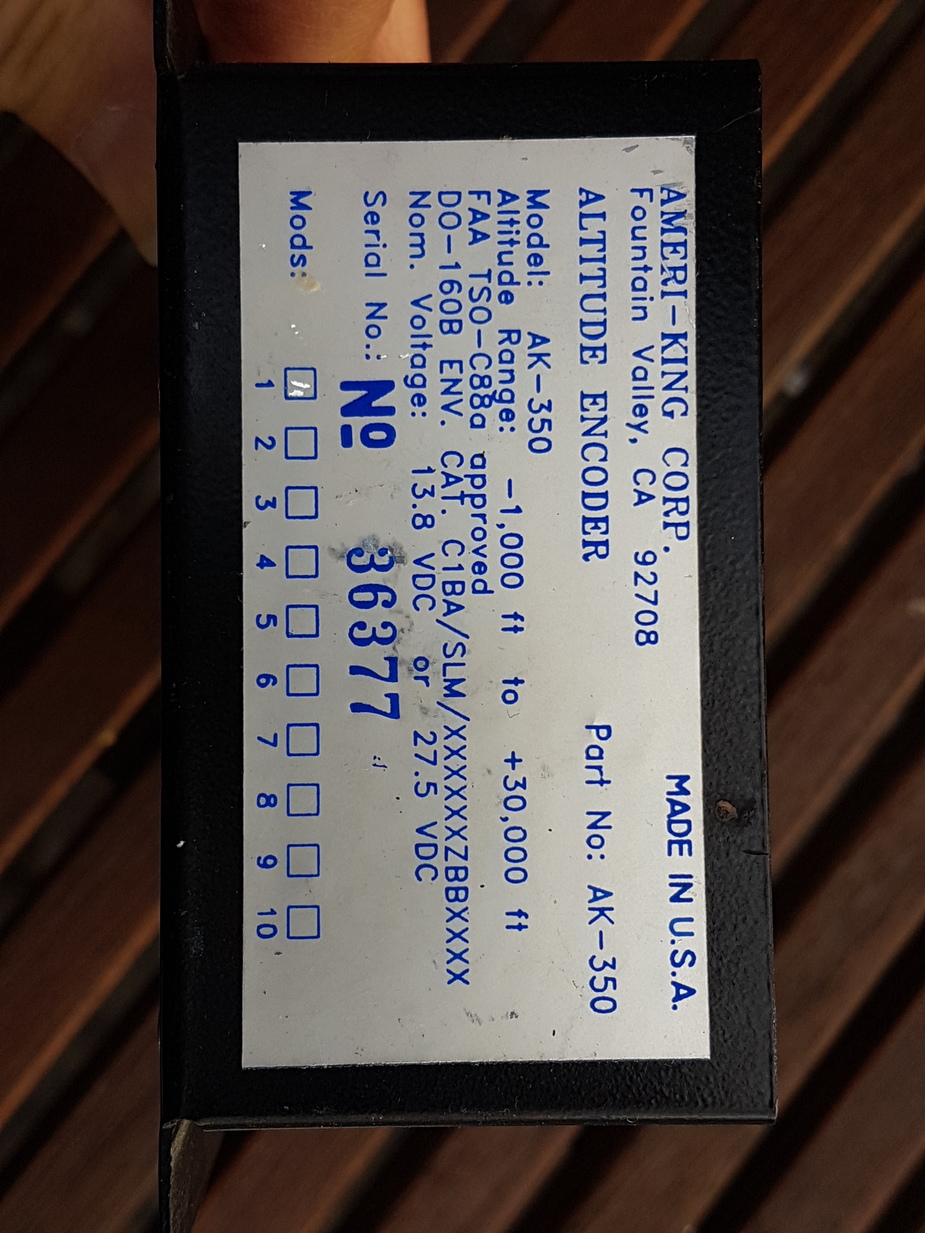

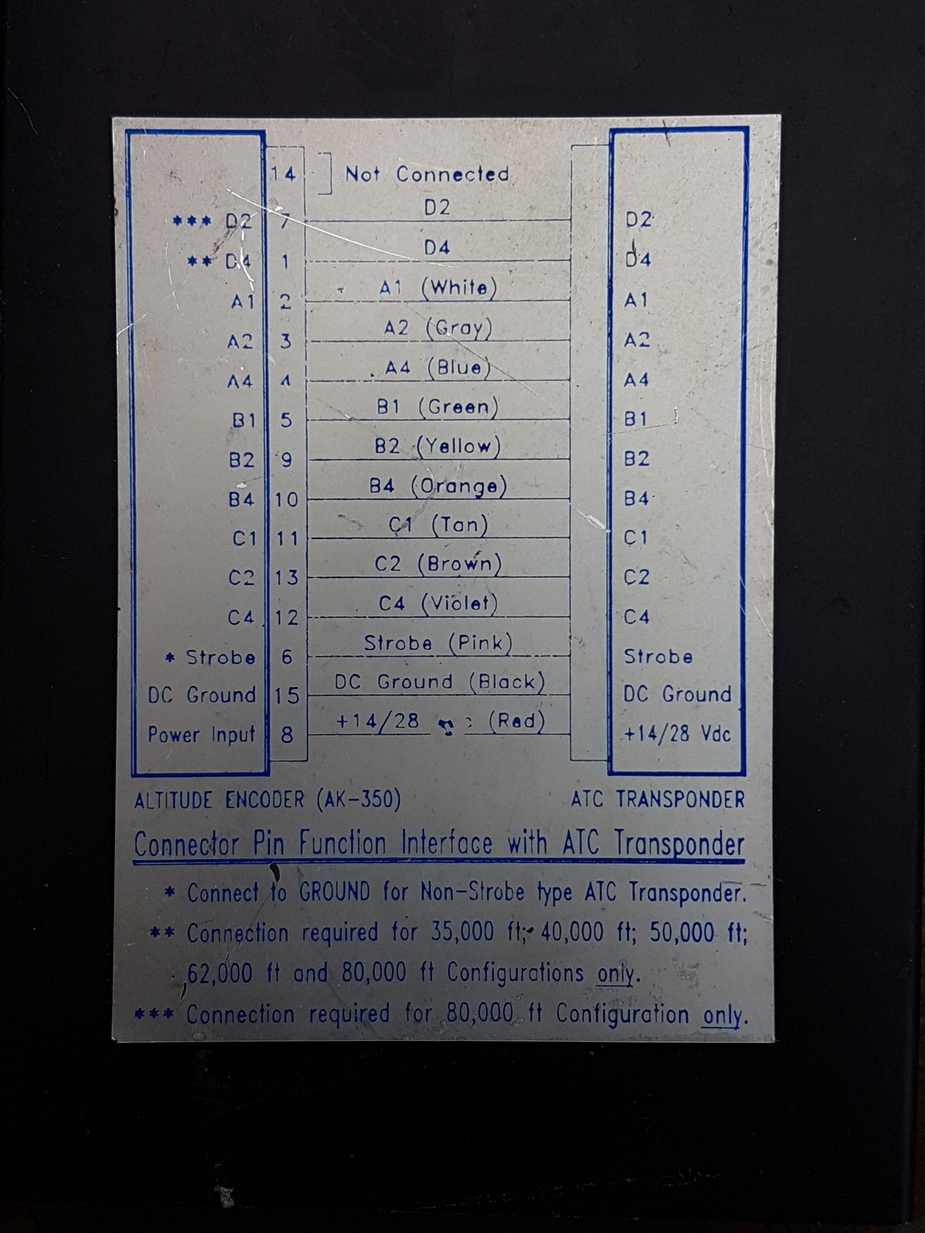

Here is another altitude encoder – an AMERI-KING AK-350.

It turns out to be a copy of the NARCO one above  Same 7109 chip, same Gray code translation with an EPROM but this time it is an OTP (windowless) EPROM i.e. a “PROM”. Made around 1998 so this is ultra modern

Same 7109 chip, same Gray code translation with an EPROM but this time it is an OTP (windowless) EPROM i.e. a “PROM”. Made around 1998 so this is ultra modern  but still built conventionally. Probably the 7109 never came out in an SMT version and if you need to flow solder one big chip, plus the connector, then you may as well stick to old stuff. This design is really dirt cheap, and with a list price of about 20x the parts cost everybody in the pipeline is very happy installing these

but still built conventionally. Probably the 7109 never came out in an SMT version and if you need to flow solder one big chip, plus the connector, then you may as well stick to old stuff. This design is really dirt cheap, and with a list price of about 20x the parts cost everybody in the pipeline is very happy installing these

Note that also like the NARCO one the TSO certification is fake, due to the temp range of the A-D converter. Another fake-TSO indicator is an ICL7660CPA which is 0-70C also

This one may even be working and I will keep it for experimentation in case I one day build something which needs a pressure altitude.

Obviously there is no factory calibration in these encoders, apart from the zero and span. Yet, lots of altimeters etc fail the FAA 2-yearly static check due to a nonlinearity which can’t be tweaked by tweaking the subscale position. If this design was implemented the obvious way i.e. with a microcontroller then you could factory-load a whole calibration curve which would give you a head start.

I wonder how many of these crappy encoders get chucked on the scrap heap because of this. But I suppose it is good business for everyone – so long as they all make the same design and nobody rocks the boat.