I think that anything that requires a POH change is a Major mod, under EASA or FAA. And improving a cowling so it gives you a few kt extra would be a POH change, in the Performance section.

It works both ways; a speed loss would trigger a POH change too i.e. a lot more certification work, which is why Socata put retractable footsteps on the GT, in year 2000, so they could carry on with the 1988 POH and call the GT “Mod 151”

OTOH if there was no speed gain, then it should be OK (it’s not much worse than a custom baffle kit) but that’s really perverse… we should be saving fuel if possible.

If anyone knows othewise, please post.

The POH reflects what the test pilots could get out of one sample aircraft. Most production aircraft may do better or worse performance-wise. Only the Limitations section is binding.

Peter wrote:

And improving a cowling so it gives you a few kt extra would be a POH change, in the Performance section.

I don’t think this is correct. There are many STCs that improve performance and they do not come with POH changes Look at all the “knots2u” stuff, LoPresti, etc. The only thing they say is that performance will be equal or better. I believe the JetProp turbine conversion of the PA46 works the same way, their performance data is not part of the POH, the previous data still applies. They don’t even give you numbers for takeoff distance etc.

Yes; probably right. However a lot of these come with an STC (the Jetprop does for sure!) and all these aspects would have been a required consideration under the STC.

I don’t think one could market a modified cowling without an STC, irrespective of whether there is any reason for it. It is hard enough to get an engineer to install a Concorde battery in place of a Gill, without an STC

does the fact that 100 series Jodels are Annex II aircraft change anything?

AFAIK national CAAs would be the decision makers?

i’ve been following the speed jojo for a couple of years now and I’m truly impressed wih speed improvements they achieved.

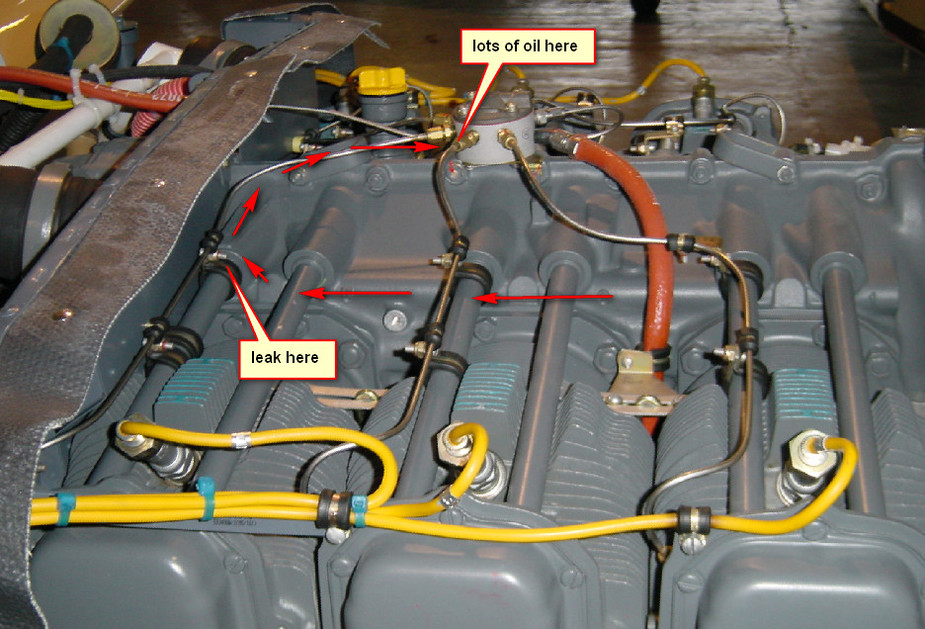

I have had an interesting example of how the airflow under a cowling works:

The leaky pushrod shroud seal was easy to replace.

(The engine pic is from 2002)

I have now installed the #2 and #6 baffle kit from GAMI and the cylinder temps have gone down significantly. Success.

I have now installed the #2 and #6 baffle kit from GAMI

I assume this is in a bonanza, correct?

Peter,

you’ve seen LoPresti stuff more than you would know. Roy LoPresti and their people are responsible for quite a few airplane clean ups, many of which were done while he was working for the company who built the airplanes. The most prominent ones were:

Grumman AA5. LoPresti is responsible for the changes made to the Grumman Traveller primarily to the cowling into what became the Cheetah and later the Tiger. The difference in performance and handling between the Traveller and the Cheetah are quite pronounced: around 6 kts cruise speed and a much better wnb envelope. The Tiger has a cruise speed of almost 140 kts, same as the original Arrow II/III but with fixed prop and gear.

Mooney. LoPresti came on board and turned the F model into the J. The difference is striking. The J is a 160 kt airplane whereas the F is a good 10 kts less. The cowling he made for the J has much smaller air inlets but keeps the engine much cooler than the gaping mouth of the C to F models. There is a cowl closure available for the C-F which closes off the lower part of the gaping hole, it’s relatively easy to install and not too costly but after all reports massively increases engine cooling apart from gaining 3-5 kts of speed.

That is the original air inlet. It is so bad that most of the air coming in there reverses flow and also goes out there, pretty much how John Deakin describes it.

This is a C model with the LASAR cowl closure.

This is a modified E model, which has the LoPresti 201 cowl (available for the E and F) as well as the 201 windscreen. This particular one is owned by Flaemming Pederson and has probably every speed mod available as well as 15 hours endurance. It has flown around the world.

LoPresti has done a lot more work for almost everyone, in the case of cowlings not only with speed in mind but in many cases improved cooling.

Clearly, to achieve better airflow you need to have baffles formed on the inside of the upper cowling, which come down onto the engine crankcase with baffle seals of some sort.

Not trivial, due to the fuel injector pipes in the way.