Only that they are not marked, or the mark is of no value in assisting the tracking down of the OEM / verifying it is the same part.

Most things “can” be marked, of course. It can just get a bit expensive; prohibitively so in some cases. Marking a paper clip would probably cost more than making it.

And as per my last post the marking can be deliberately misleading to ensure that the P/N does not match even if the part is the same by inspection.

This is where the FAA A&P has the authority to declare a part “airworthy” by inspection. And that is what so dramatically facilitates long term safe operation of many old planes, where parts have to be cannibalised. It also frustrates the establishment of ripoff practices with current parts; something the European system has always supported rather well. The counter argument is that the A&P is sticking his neck out when doing that, and not all want to do that, but hey “liability” is always only just around the corner in all GA maintenance.

Actually, many current Socata parts are cannibalised. They no longer make a lot of bits and run a programme for sourcing parts from wrecked / abandoned airframes, which they buy in (they told me this). The key difference is that they have a 145-certified laser printer for generating the EASA-1 form

Again, those of us who may utilize parts made many years ago, whether used or NOS, have little interest for what could be done and a substantial interest in using them as they are now.

Another interesting aspect of this ridiculous law is that it prevents parts from being refinished, if it erases the manufacturer markings. So much for corrosion control.

No A&P on light GA aircraft I’ve ever met views utilizing unserialized etc parts without an 8130 as ‘sticking his neck out’, scrounging parts is one of the basic aspects of getting jobs done. GA would otherwise end up as it is under EASA, not a good thing.

Picking up this concession again but this time in more detail and with a “case study”.

Take the example of a Socata TB landing gear squat switch – mentioned here, made by Crouzet in France (of course) and sold via the Socata dealer pipeline for £1200+VAT (of course)

The same switch is available for £300+ (of course) from normal trade suppliers of industrial switches, with flying leads (no connector).

Now let me pick up the conditions again:

(c) in the case of ELA1 or ELA2 aircraft, a part or appliance that is:

1. not life-limited, nor part of the primary structure, nor part of the flight controls;

2. manufactured in conformity to applicable design;

3. marked in accordance with Subpart Q;

4. identified for installation in the specific aircraft;

5. to be installed in an aircraft for which the owner has verified compliance with the conditions 1 through 4 and has accepted responsibility for this compliance.

1) is clearly met.

2) is clearly met by inspection of the data sheet, unless someone argues that we cannot prove there isn’t a custom spec from Socata to Crouzet (there prob99 is because that is precisely how the restrictive practice is operated, but you will never find this spec)

3) is probably met (see posts further above)

4) I am still not sure about this one… identified by who? It is obvious by inspection.

5) is met by the owner taking responsibility (this whole concession is based on that principle)

BUT the P/N is not exactly the same, because Socata (or somebody, maybe Crouzet) fit a connector and allocate a new P/N.

One could throw this around a bit… is the connector an integral part of the switch? It is a connector style used in a Vauxhall Viva (or the contemporary French equivalent)

In the FAA system, an A&P has the authority to declare the switch itself to be suitable (EASA would never allow that) by inspection, but you still have the “connector” debate.

If you are replacing the switch, one could just cut off the wires leaving the connector in place, and fit the new switch by soldering/crimping the wires. That would be dumb (because while the switch is a high grade waterproof item, the connector which Socata sell it with is utter shite) but it might sufficiently lubricate the debate with the installing mechanic.

The reason I am typing this is because I know of several cases where the Part M company insisted on the Socata part. Not for any reason; they just did. In one case the reason for replacement was because the long-neglected syndicate aircraft had the switches corroded right through their cases.

Another data point: the same issue exists with Facet/Bendix style fuel pumps used on both cars and carbureted planes. The electrical connector is different on the earlier version supplied for aircraft, although not clearly better, there are also identical looking car units with different delivery pressure and check valve arrangements and in the 50+ years since they were first installed on planes the design has been sold to another manufacturer and apparently the internal design has been improved. I think in this case they are NOT legal to install on a plane under either FAA or EASA regulations. An FAA A&P cannot declare a car part to be suitable for an aircraft, he is limited to installing the correct part number from the correct manufacturer after inspection of the actual part (not just paperwork or stickers) to ensure that is the case. However, what happens in the field worldwide given no other options is that people just select the technically correct version and install them, presumably making a legitimate looking logbook entry referencing the airframe manufacturers parts number. I plucked this photo from a advert of a plane for sale in Europe – personally I would have removed the Facet sticker. No legal part is available AFAIK for several type certified types using this pump.

So…  Installing car parts is not the intent of the FAA regulation and certainly not the intent of the EASA regulation, but neither actually prevents it, and no value is added by nonsense paperwork. The mechanic in either case uses his judgement, knows what he’s doing and does it. FAA system just ends up being more efficient and equally safe.

Installing car parts is not the intent of the FAA regulation and certainly not the intent of the EASA regulation, but neither actually prevents it, and no value is added by nonsense paperwork. The mechanic in either case uses his judgement, knows what he’s doing and does it. FAA system just ends up being more efficient and equally safe.

I could go on and tell you about another part I just received with an EASA 1 form that is quite clearly an non-PMA (or equivalent) aftermarket replica of the original part that is no longer available from anybody. I’m very happy to have it, and past experience says it will work fine, but on several levels the paperwork system is a charade.

It is possible (although I think unlikely) that the clearly non-OEM part I just received with EASA1 form was approved via coordination with the TC holder, which still exists but does not supply any parts. However it was supplied as the original part number so physical inspection contradicts the paperwork trail. My guess is that consultation with the TC holder and subsequent arrangements with the current part manufacturer were done informally, and the informal practice is tolerated because the ‘right people’ were involved, as per European custom when the elaborate, impractical process is too hard.

Do I care about any of the above, for my plane? Not even the slightest bit and the paperwork is in any case of no value to me. I only mention it here because it fits the topic.

The problem in Europe is that, for airfield-political reasons, most owners don’t have any option other than to do as their maintenance company says. And this is equally true for an N-reg (in most cases).

Peter wrote:

Picking up this concession again but this time in more detail and with a “case study”.

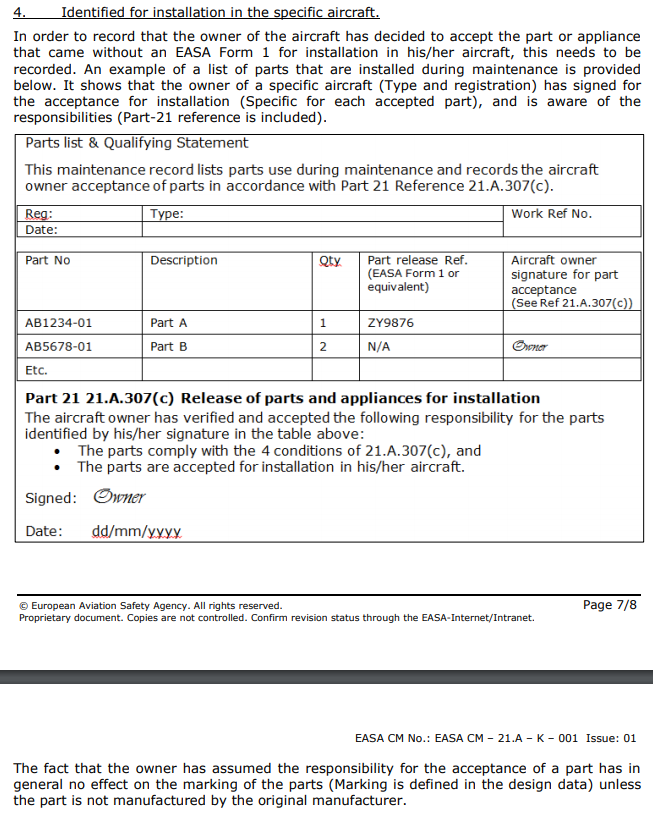

I think some of your questions are answered in the certification memo. local copy. In particular I think the “identification” thing is much easier than you feared.

But you raise some interesting issues. Let me see what I can find out from the EASA GA team.

It would appear that Section 4 simply says that the “identification” is merely a declaration by the aircraft owner

Otherwise, I can’t decipher the phraseology…

The last paragraph is another problem, given that with many aviation parts the OEM deliberately conceals the manufacturer’s identity.

Here is another case study for @bookworm.

A Weldon electric fuel pump

1 x Z00.N6097727220 (or Z00.N6097727226) electric fuel pump USD 3021.00 New with EASA Form 1. Overhauled not available.

1 x B8120H from a US supplier USD 960.00 with an 8130-3 but overhauled so “not installable” on an EASA-reg except possibly via the above concession.

OK; one can’t directly compare new with overhauled, and the shipping from the US will be about $200 versus say $100 from France, but

Would this US supplied one tick all the requirements?

We have done this before here (@zozi may be interested) and again here albeit with a more “explosive” outcome  I am not sure whether the “critical part” discussion from 2016 is still applicable today.

I am not sure whether the “critical part” discussion from 2016 is still applicable today.

EDIT: Outright new with 8130-3 is $1550 which is about half the cost of the exact same one with an EASA-1 form.