Socata liked these a lot

and I heard that they were commonly used on US aircraft up to the 1970s.

What is the reason?

Sometimes it is hard to understand e.g. my ALT FIELD CB is non-pullable

which means that if you get an alternator failure (one not caused by the failure of the field current) you don’t have the option of shedding several amps of spurious load – caused by the voltage regulator driving the field coil flat out. Being able to shed this load could extend the battery life by 20-30% which is quite a lot when you are trying to get back on the ground with a working radio and nav…

Also you have no way to isolate the various circuits for troubleshooting on the ground.

I have re-built the whole CB panel, at a substantial cost of c. €1000 in Klixon 7477 CBs (except the bottom row which are the original ones – those are huge and are tied to a solid copper busbar). All are of course pullable.

Those Socata (made by ETA) CBs are pricey and I will be selling the whole lot

I completely agree. I was in a PA32R the other day, and one of my principal thoughts was “yeah, but how do I pull the CBs?” How do you handle an electrical fire, for example? It’s daft.

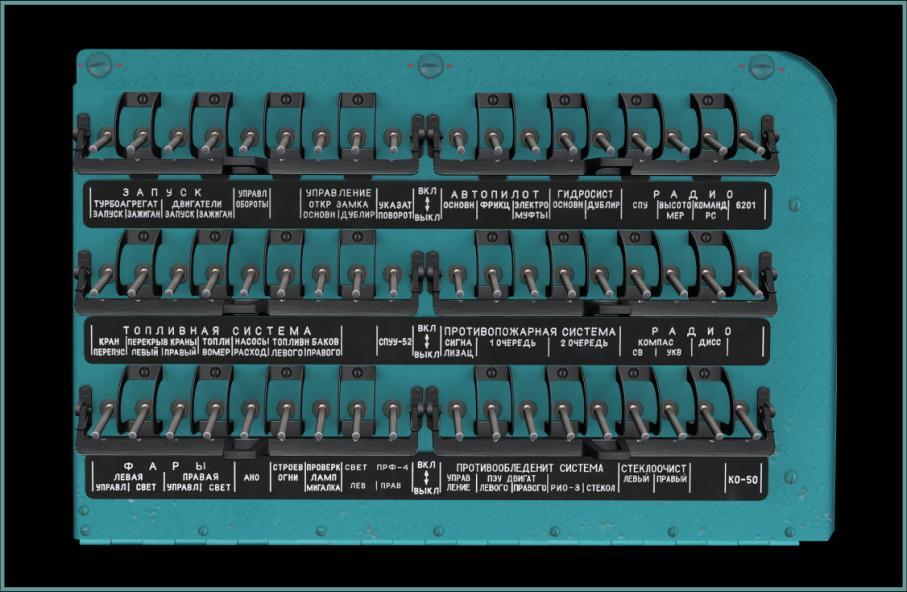

I like the solution used in Eastern Bloc aircraft, which had no separate circuit breakers – every toggle switch had a circuit breaker built in. Here is a CB panel on a Mi-8 helicopter:

I never understood why they need to be fuses at all – the later models have switches that trip, like Piper etc does. Or like that Russian picture – much better. Fuses suck and even with colored collars on them, they’re a pain in the a**.

I think the issues with combined switches and CBs are:

These are the combined ones Socata use; an obscure French make

As per the last point above, the feed to (at least some of) these is protected at (I think) 80A which means the wire feeding them needs to be really thick. It would have been far better to stick another seven CBs into the already huge CB panel

and have seven good quality toggle switches (APEM are French so would qualify  – they use them in the TBM) in the panel shown.

– they use them in the TBM) in the panel shown.

In the CB panel above, only the bottom row of CBs have an unprotected feed.

Was this the type used in US aircraft – Potter & Brumfield? I have usually heard of it mentioned in the same sentence as “junk”

AdamFrisch wrote:

I never understood why they need to be fuses at all

Fuses are another matter. The aircraft I learnt on had fuses, rather than CBs, and they are a quantum leap worse, as you have to carry spares of all sizes, and the diagnostic act of resetting blows a/the spare.

I remember thinking, when I first flew with CBs rather than fuses, “what a great idea.” But I only took my house from fuses to CBs about five years ago!

Peter.

I’m going to take a guess that the French Switch / CB’s are maufacured by ETA. Robin have used these for years and now have moved on to use a much lighter and easier to fit type.

The advantage of the type of ETA switches is you can get them direct from the manufacturers at a much lower price than from Robin.

During my prolonged Avionic refit I needed a splitter for the antenna line. This has a Garmin part number and Garmin quote the manufacturers part number in the install manual. The cost to me from a major avionics company was in the order of £220, the same item from a well known parts supplier was £105 ( both +VAT & postage ). Direct from the manufacturers U.K. agent it cost £58 inc VAT & delivery. Having told an independent avionic installer about this he has got the agent to supply these items few £ cheaper if he buys five at a time !

Not ETA curiously. Diruptor in France. But good luck with this one:

Their catalogue here doesn’t show anything like this part (obviously). So it looks like another Socata-agreed-exclusivity P/N. The P/N doesn’t come up on google at all. They are not too pricey – below 100 quid I think. However Socata prices have been rocketing lately; I reckon they have doubled in the last few years. Somebody got a quote around 3k for the aileron hinge kit which was 1k some years ago.

The other P/N googles to this with no resolution.

Only the French would manufacture a CB for one application, I recognise some of the other Disruptor products from various French Aircraft.

Fortunately Robin have now largely stopped using French stuff and have found the Aircraft spruce catalog .

I suspect this CB was “current” when the TB was designed c. 1978. and Socata entered into an agreement with Diruptor to keep them available, even at some inflated price.

Eventually that will come to an end and eventually Socata will develop a conversion kit of some sort, which will force you to replace the whole lot for a few k €

It’s always a problem with long running products using commercial parts.

I am told that Airbus use American parts. Unsurprising; nobody in the US (or most of the world) would buy an airliner which needs everything shipped over from France.