People have been “abandoning” aircraft for as long as they’ve been building them. The real issue is how many there are in relation to demand, and how difficult it is to repair them (including regulatory constraints in any given area) and to find parts either NOS or from aircraft that have been “abandoned”. Neither of mine have had manufacturer parts support for many decades, long before there was an internet that makes everything so much easier, and unless they’re damaged in a pretty substantial way there is little doubt they’ll be flying long after I’m dead and gone.

Fix ’em and fly ’em

Aircraft which are operated as C of A certified will require certified parts for any required maintenance and repair. Yes, it may be possible to obtain used certified airframe parts depending upon resources and the permission to identify used parts as certified, but use parts, are just that – used. They probably have had a long service life of their own before being offered up for sale as used. If the airframe has been designed so well that structural fatigue and wear are not issues in long term maintainability – excellent! This is the case for some aircraft, just keep inspecting, and not finding any defects! Or, as some types, there are a multitude of simple repairs possible with common materials possible for the airframe, so if a defect is found, the repair is practical, and lost cost. An example of this is that most Cessna singles wing spars are made up of folded aluminum sheet, with common extruded angle riveted – though a lot of work, these could be made “in the field” and Cessna offers some structural repair data to point the repairer down this road. Piper low wing aircraft use special aluminum extruded “I” beams for spars, which cannot be made “in the field”. If you must replace a Piper spar, you’ll need a source of airworthy Piper origin parts.

The Blanik L-13 is an example of a good aircraft, which had a design problem become evident later in its service life, and generally was not economical to repair. Gomolzig in Germany designed and approved a repair kit, which I was shown during a factory visit there. It looked magnificent, though I agree that the cost to purchase and install might have been prohibitive. Less common aircraft place the owner at a greater risk that something goes wrong, and there is not enough economic incentive for “the market” to produce repair parts. I think about this, as I own two type certified aircraft, of which only 38 were made in total, and only seven are flying. If I have a structural defect, I’ll be on my own to work out an approved repair. The designer has passed away, and the type certificate holder has no capacity to provide any product support. Happily, when I bought the first of the two aircraft, a pleasing supply of brand new original parts came along, and most of the airframe could be repaired with standard materials if needed.

As said, choose the type which will satisfy your operational need, with a lesser dependence on going “really fast”. If “really fast” in the GA context is needed, Think of a newer very high performance single, or light turbine, and pay the cost. But no matter what you choose to purchase, or invest more into, assure yourself that there will be a longer term way for you to keep it operational at all. Manufacturers of legacy GA aircraft are showing themselves to be less concerned with economical support for those older aircraft.

Pilot_DAR wrote:

Less common aircraft place the owner at a greater risk that something goes wrong, and there is not enough economic incentive for “the market” to produce repair parts. I think about this, as I own two type certified aircraft, of which only 38 were made in total, and only seven are flying. If I have a structural defect, I’ll be on my own to work out an approved repair. The designer has passed away, and the type certificate holder has no capacity to provide any product support. Happily, when I bought the first of the two aircraft, a pleasing supply of brand new original parts came along, and most of the airframe could be repaired with standard materials if needed.

I’ve found in lots of experience with low volume stuff that the “luckily there is stash of parts that nobody wants” situation is almost always the case, and the Internet is a huge asset in finding it. Regardless, at 50 hrs per year per plane and with 1100 or 1800 total hours on the airframes, my planes need essentially no airframe parts and assuming I don’t crash them, that situation is never going to change in my lifetime.

There is also a practical maintenance related advantage in owning a plane that is likely the only one of its type that any A&P IA has ever seen, or will ever see. Coming back on topic, that also means that fairings might change here and there to provide a little extra speed.

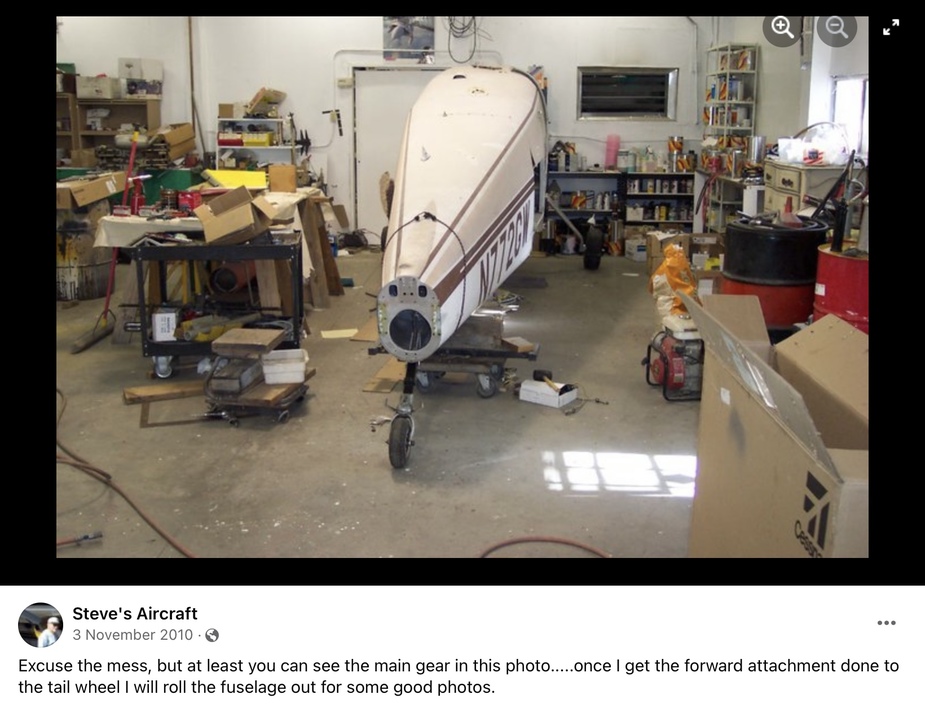

A search on PA28 speed mods turned up this 😆