I think this say it all, from Ted’s link above

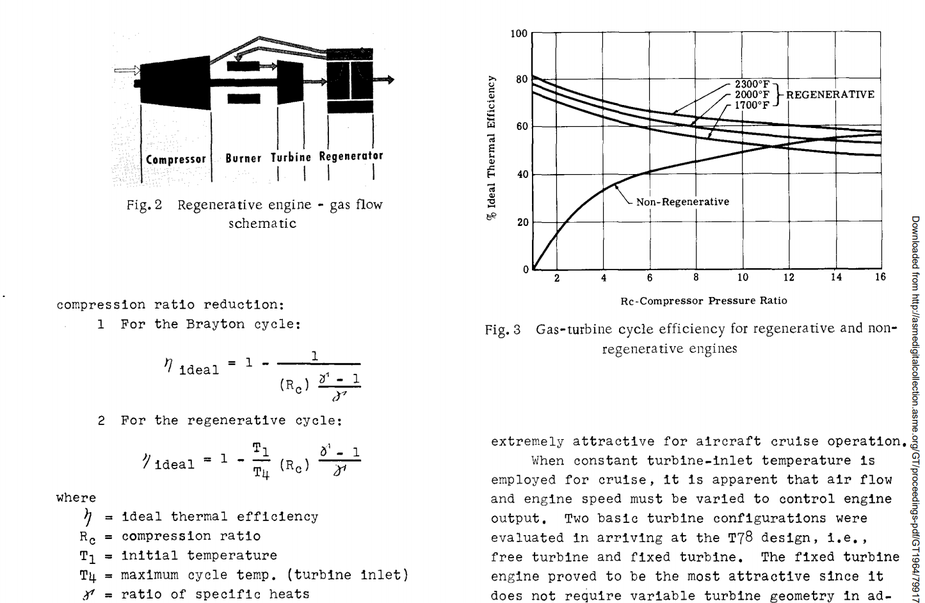

A single small centrifugal compressor has a CR of about 4-5 perhaps at nominal load. The maximum efficiency it can achieve is 35-40%, which translates to about 20% for a real unit. Increasing the CR, and a recuperator will have negative effect, as would be the case for all modern aero-turbines in operation. This is very expensive, it makes little sense to pay €150-200 for an engine with the same performance as a Rotax.

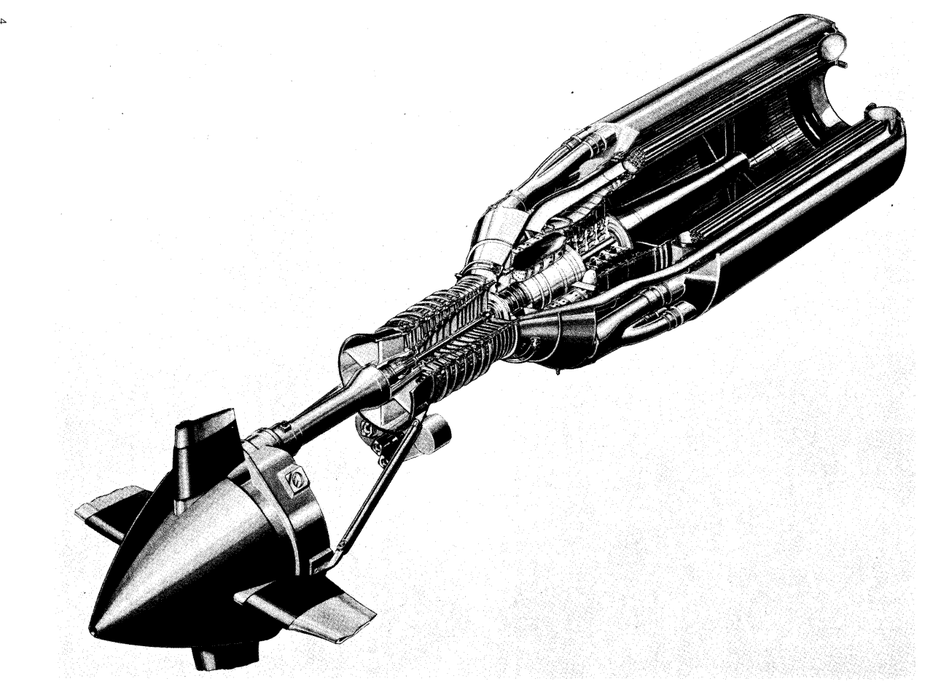

The recuperator of the Allison engine is not exactly small compared with rest of the engine:

Well it certainly is doable then. It has already been done, more than 50 years ago, from here:

The T78-A-2 was originally designed as a potential replacement for the Allison T56 turboprop in the Lockheed P-3A ASW aircraft. It was also adaptable to airborne early warning aircraft based on Navy carriers, for large transports, and other applications where long endurance or low fuel consumption was of prime importance.

The T78 incorporated a regenerator system that was intended to reduce specific fuel consumption at low power settings and, thus greatly extend long-range and “on station” capabilities. The basic principle of regeneration involved reclamation of turbine exhaust heat to increase the temperature of compressor discharge air, thus reducing the amount of fuel required for the most efficient engine operating temperature.

By the spring of 1965, Allison had run the T78 at up to 85% of rated power during a one-hour test. Testing continued for a short period, but the engine was not put into production. Apparently some people in the Navy were opposed to increasing time on station for the P-3 because of crew fatigue problems.

In other words, it wasn’t put into production because it worked too well  The crew couldn’t handle it. Rather amazing.

The crew couldn’t handle it. Rather amazing.

Dud link. Has a timeout.

I’d guess a recuperator effective enough to achieve reasonable fuel consumption with a 200 HP turboprop won’t fit easily on the airframe.

People have been working that problem for a while.

This was done by some firm here which did a floation on the AIM, doing turbine engine driven portable generators, and went bust not long after. The heat recovery stuff was much bigger than the engine itself.

Seem quite complex to build a turbine that is efficient at variable speeds. Which I think is the difficult part of the problem.

Perhaps the RB211 of the GA world

link fixed

Ultranomad wrote:

but something is impeding its wide adoption

Cost is definitely a bit of that something among other things. However, the PBS pure jet version of the engine is used in more and more versions of this:

Not exactly a practical plane, but certainly a cool plane

Silvaire wrote:

I’d guess a recuperator effective enough to achieve reasonable fuel consumption with a 200 HP turboprop won’t fit easily on the airframe.

A single stage centrifugal compressor can only compress so much. This translates to high exhaust temperature because you only got so much pressure to decompress. Lowering the exhaust gas temp with a recuperator while heating the inlet temperature will increase the efficiency quite a lot (relatively speaking) because it is so low to start with. It certainly works in industrial settings, but making it compact and light enough for a TP in an aircraft? Maybe.

I’d guess a recuperator effective enough to achieve reasonable fuel consumption with a 200 HP turboprop won’t fit easily on the airframe.

People have been working that problem for a while.

I think the one posted by Ultranomad above is the one here from 2015.

Aero Friedrichshafen always has a number of these. Same exhibits every time.

The SFC on these is probably quite poor.

0fficer wrote:

Slightly smaller

Wow, that one might be interesting for hybrid installation. With an electric motor (driving the same constant speed propeller) providing additional power for takeoff and climb, say for 15-20 minutes, and the turbine to provide for cruise power and some recharge capability. Of course in typical SEP it would have to be operated close to maximum rated power output.

But in fact, the same is true for the other turbines, too. A 200hp Turbine in combination with an electric motor should be sufficient to replace anything up to at least 300hp of AVGAS burners. If it really provides 90% maximum continuous power this is 180hp, so you get 60% of 300hp from the turbine alone, sufficient for cruise.

The total weight could in fact be exactly the same as the 300hp Conti/Lyco.

Slightly smaller: https://www.turbotech-aero.com/solutions/

@Ultranomad could it be certification requirements in Europe for the design organisation?

The OP is for the NA/Australian entity…