Peter wrote:

That method will break if you ever see less than 1G, which will happen briefly at top of climb, etc

That’s what the 1min rolling average is to prevent :-)

You can do +1G manuvres for as long as you like (eg a steep turn for 10 minutes) but in a carburetted, non-inverted, non-aerobatic plane you can’t maintain less than 1G for more than a few seconds.

Peter wrote:

How is this solved on airliners? They do have fairly accurate gauges – as well as totalisers.

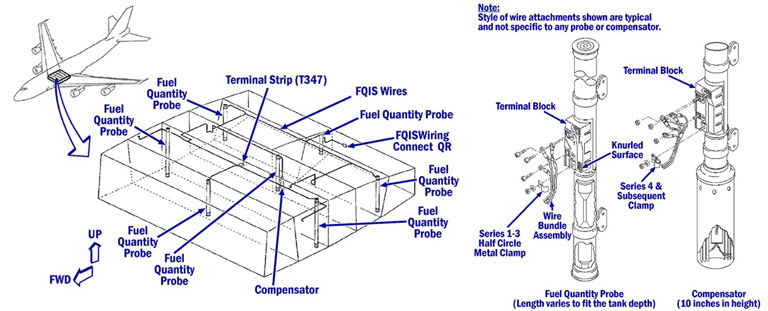

They have several capacitive sensors (tube type) in each tank whose readings get summed up. This will equal out any attitude changes and sloshing. Usually there are also density and temperature sensors (“compensators”). A microprocessor takes all those measurements and derives a calibrated fuel mass from them.

Quick googling found this schematic of a B747 belly tank (taken from the accident report of “TWA 800” where damaged insulation of one of the many cables leading to those sensors caused the fumes in the empty tank to ignite):

And then there are flow meters and totalisers.

Peter wrote:

How is this solved on airliners? They do have fairly accurate gauges – as well as totalisers.

My memory says that each tank has several capacitive sensors (vertical tubes distributed across the tank). I recall it can go into tens per tank. I’m not saying all of them do it that way. That’s how they achieve that accuracy because individually they’re not that accurate (I never saw the specs, that’s what I was told). Also, IIRC I was told that the software can exclude failed sensors. That was I believe on some Airbus.

The Mustang has 5 sensors per side and there is also an adjustment made for temperature impact on density.

alioth wrote:

As a real anorak myself, I would just make it so that the gauge can only move downwards until reset/power cycled, and given you’re not likely to maintain >1G for long, this would be fine and can all be done in software. Also use a rolling average as the level, a rolling average of the last 1 minute should be good enough. My plane doesn’t have an in-flight refuelling probe, so the only way the fuel level can increase is when the plane is stopped, switched off, at the fuel pump :-)

That wouldn’t work on a Cub, or most tail wheel aircraft. You will almost always measure different pressure when you cant a tank, as in 3 point attitude (could be more or less, depending on the shape of the tank and how much is in it) Then you would need some kind of switch, two dials or something, and two calibration curves.