Sorry, I only know of storing outside and not being flown for over a year, but it might have been stored in some old NVA shelter, I don’t know. They aren’t very dry. But when we inspected the aircraft, there has been water standing in other parts of the aircraft and many Moranes aren’t corrosion proofed. But it shows that it’s not only a problem of wooden aircraft.

The best thing you can do with a wooden aircraft is to store it in a wooden hangar. Best moisture regulation you can ask for. It isn’t bad for metal aircraft either.

Peter, are the DA40/42 local to you ? We have had no metal hardware issues with the DA40/42 aircraft we maintain but all of these don’t live on the coast.

I keep my TB20 in a rather huge WW2 hangar which survived after 1945 serving the French and later the US Army as a helicopter repair shop. The hangar walls are made of red bricks which do an excellent job in dissipating moisture. Before I was the happy renter ( for ten years ) of a garage near my city flat that had the same red bricks walls -

on average totally dry air in there – I had a lot of tools on the wall for my motorcycle ( MV Agusta 750 ) – never a single stain of rust on them. So if I would construct a hangar some day for my private use guess which material I choose …

A_and_C wrote:

Peter, are the DA40/42 local to you ? We have had no metal hardware issues with the DA40/42 aircraft we maintain but all of these don’t live on the coast.

I have seen some corroded gear components on older aircraft, never seen these issues either, certainly not to the extend where the cost of replacement would be a significant part of maintenance cost.

In general keeping the aircraft hangared and clean will reduce corrosion issues. Cleaning the aircraft is also a very good airframe inspection, as with regular cleaning, and on a clean aircraft you will notice small defects early, which can be solved before becoming major issues.

We did a couple of test flights today in a Robin DR401 with Dick de Ruiter from Transal, the Robin dealer in The Netherlands.

The performance is great. With four persons on board and full fuel we were airborne in less than 400m from a grass strip.

Impressive climb performance. We did 900fpm at MTOW.

Cruise performance is ok. It was doing +/- 120KIAS at 1500ft with 80% power.

The short wings felt very stiff. Very direct on the controls. Aerodynamically it’s very stable: if you keep your hands off the controls it will just continue in level flight.

The large glass canopy offers a helicopter-like view.

The space on the back seats is a bit cramped. I joined one flight on the back seat and was touching the ceiling with my headset.

The space in the front is OK.

A point of attention is the position of the G500, which is slightly too high and the top of the screen (that shows data like DTK / TRK / WPT / etc) is not readable as it falls behind the dashboard edge. We were told that it is possible to order the DR401 with the G500 mounted a bit lower.

The cabin is surprisingly quiet. It must be the firewall which is well isolated. Also, the wooden structure absorbs some of the noise/vibrations.

The baggage compartiment is quite tiny. You can put a cabin size case in it, but that’s about it.

The latest CD155 diesel engines have a TBR of 2100 hours. The engine runs very smooth and it’s a perfect match with the light Robin airframe.

This airplane offers a lot of flying fun and if you’re in the market for a diesel aircraft, you should give it a go…

Interesting report, Lenthamen. 120kt IAS at 80% is much slower than other IFR tourers and suggests a large tradeoff between wing loading (i.e. Vs) and cruise speed. That’s where the good short field perf comes from. According to this Vs2 is 72km/hr which is only 39kt which is vastly lower than the typical IFR tourer which is 59kt and just under the SE cert requirement.

What was the fuel flow at 80%?

Yes the DA40/42 cases were near the sea.

Peter wrote:

What was the fuel flow at 80%?

According to the POH its 25,8 l/h

The good things is that it keeps this power all the way up to its service ceiling. So at 16000 ft you’ll get 143KTAS, still burning 25l of jet fuel per hour.

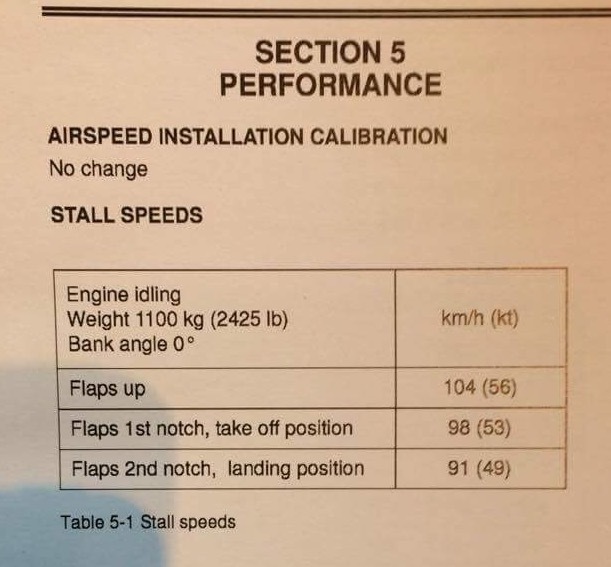

These are the published stall speeds:

I agree that there is a trade off between climb performance and cruise speed. It’s about 5kts if you compare it to the DA40 with the same engine.

But you get a lot of utility in return.

Lycoming 0-360 at 4000 meters would give you 137 knots burning 34 liters of mogas

Those are POH DR-253 figures

The Robin is a neat plane, the most interesting new plane to me when I visited AERO Friedrichshafen a few years ago. The relatively low wing loading is why you can climb out with four people at 900 fpm on only 155 HP. If you have time and opportunity to climb way up high, then going fast is also an option. I bet most operators spend most of their time below 10,000 ft, where you can get enough power with a NA engine. Mine would have a 200 HP Lycoming and I bet with that engine it climbs from sea level really well. For two hour legs with mountains or water crossings along the route, rapid climb after takeoff often saves time point to point.

Later today I’m planning to land and take off at 9000 ft density altitude, instead of continuing on to a sea level airport. It’ll take a while but the runway is pretty long. I could use a turbo today

Peter wrote:

120kt IAS at 80% is much slower than other IFR tourers

IFR tourers usually don’t have just 155 hp.

lenthamen wrote:

I agree that there is a trade off between climb performance and cruise speed. It’s about 5kts if you compare it to the DA40 with the same engine.

IIRC DA40 also has a low stall speed, 49 knots I believe (but it depends on the engine, it’s higher on the NG, and also on the MTOM, obviously, there should be a lighter version with even lower stall speed).