Having flow and maintained most GA engines and I can’t get excited about one engine over another, they all good and bad points and all require sympathetic maintenance to stay reliable.

The biggest enemy of the older engines becoming more reliable and efficient is the nature of the certification, in Europe we have the situation that EASA will except an electronic ignition system to be fitted to a Lycoming in a PA28 based on an FAA STC but will not except the same ignition system to be fitted to a Robin Lycoming engine without an EASA STC.

Bare in mind that in the UK aircraft used for flight instruction and I assume that this conversion is aimed at that market have to be maintained in accordance with LAMP (light aircraft maintenance programme). Under this all TBO recommendations have to be followed so in the case of the 912 it’s 2000 hours and no extension is allowed. Also Rotax’s manual says that these hours should be based on engine running time not airborne time.

of course this might all change with part m lite but until then I this conversion is to me economically unviable.

Under this all TBO recommendations have to be followed

My understanding was: With part M coming into effect, all EASA reg. planes (also if used within ATO) can be operated on condition.

The UK CAA didn’t interprete in that way. One hopes that will change with part m lite

Bathman wrote:

Bare in mind that in the UK aircraft used for flight instruction and I assume that this conversion is aimed at that market have to be maintained in accordance with LAMP (light aircraft maintenance programme). Under this all TBO recommendations have to be followed so in the case of the 912 it’s 2000 hours and no extension is allowed. Also Rotax’s manual says that these hours should be based on engine running time not airborne time.

If the flight instruction is non-commercial, then you can use an owner-declared maintenance programme and the CAA has no say.

Airborne Again

Sadly thats not the case in the UK. The CAA interpret all flight instruction even if its for none profit as a commercial organisation so you can’t use the SDMP.

Actually Peter my local maintenance company are more than happy to do such work. Its the ops inspectors that wont allow it and as you know if you don’t do what the ops inspectors tell you then you don’t get your approval.

So it will be interesting to see what Part M Lite brings as this may make this re-engine more cost effective.

Bathman wrote:

Sadly thats not the case in the UK. The CAA interpret all flight instruction even if its for none profit as a commercial organisation so you can’t use the SDMP.

Someone should protest that to EASA. Of course, the question might soon be moot.

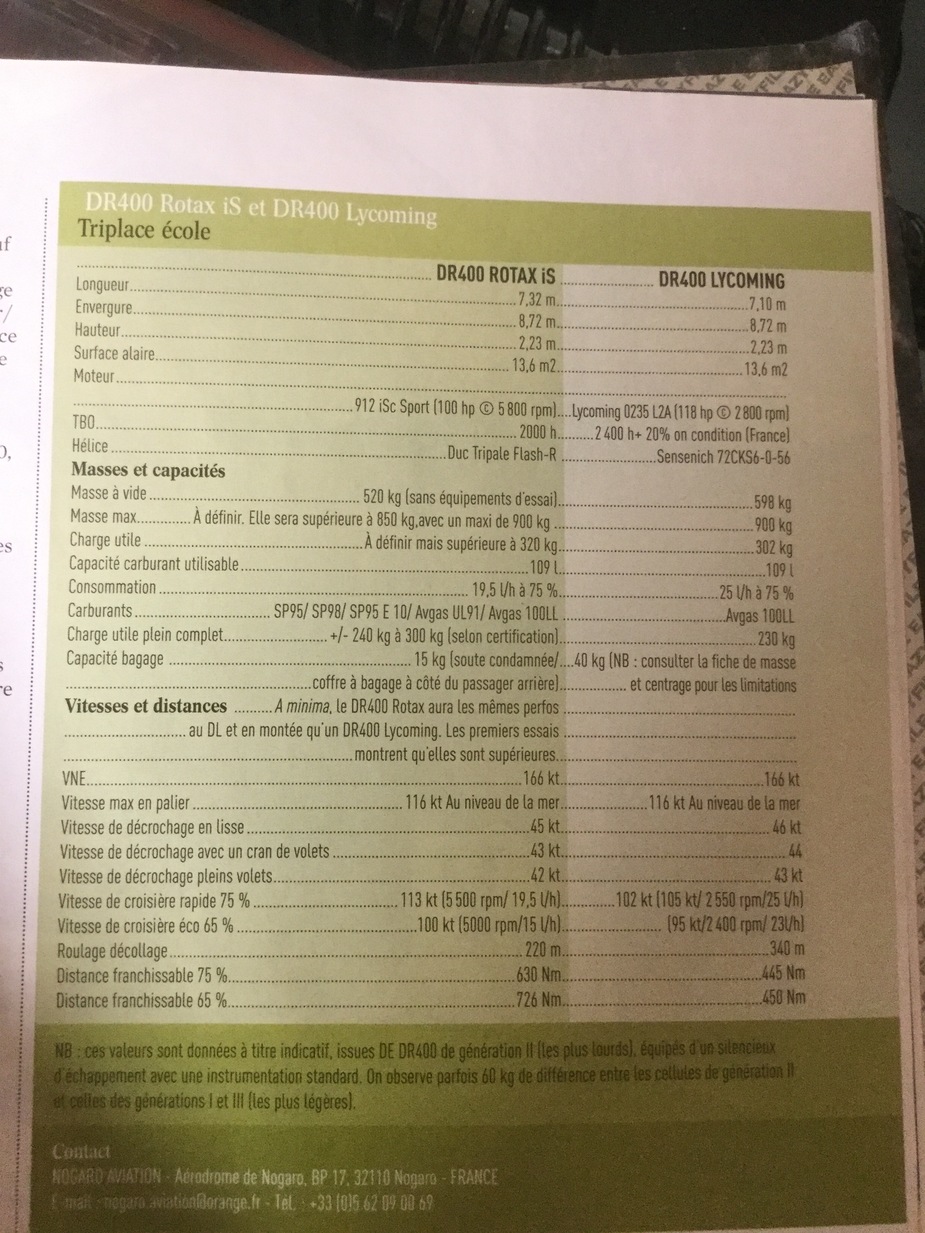

Nogaro Aviation have had an STC to fit a Rotax to Robin DR400s since 2016, and I’ve summarised an Info-Pilote magazine article dating from just before the STC was granted.

They compared the before and after performance with two aircraft, modernised F-GORZ with a 100hp Rotax 912iS, and standard F-GKQR with 118hp Lycoming O235. Generally it was a positive review, and gives a few concrete figures. Hopefully it might also help answer MedEwok’s question on price.

The Rotax version is 60kg lighter which required moving the engine forward to maintain the centre of gravity (and a new Aquila-esque cowling). Another 40kg can be saved by carrying less fuel for the same endurance/range, so possibly total 100kg lighter [compared to 18kg for the Cessna]. Full fuel is 6 hours in navigation or 8 hours of circuits. Rotaxes not liking heavy propellers, this has been replaced by a ground-adjustable 3 blade carbon fibre one from Duc Hélices. Most of the engine instruments have been replaced by a single digital screen. To keep the centre of gravity forward the baggage compartment has been sacrificed, one of the back seats being replaced with a desk and locker, turning a 2+2 into a 3 seater.

When being compared the Rotax aeroplane had an extra 10kg of test equipment, but otherwise the same load of two pilots, 4 hours fuel and limited baggage.

On the ground the Rotax was much quieter, but otherwise no differences. It has a slightly different starting sequence.

On takeoff the Rotax gave a ground roll of 220m, then under 500m to clear a 15m obstacle, with rate of climb of 720fpm. The Lycoming gave 340m ground roll, over 500m for 15m, and 620fpm.

In cruise the Rotax was 10 knots faster for 5 litres per hour less fuel.

The stall speed was near identical, with maybe 1 or 2 knots in favour of the Rotax, which also had more responsive controls.

Doing circuits (where it will spend a lot of time as a trainer) it burned 12 litres per hour compared to ‘in the low 20s’ for the Lycoming. It was noted the Lycoming will be full rich almost all the time, and that carburettor heat adds approx 3 litres per hour; the Rotax has sensors in the exhaust to adjust the mixture, and having injectors removes the carburettor heat.

The article estimated hourly savings in the region of 20-30€ per hour. This is from reduced fuel consumption and the ability to use cheaper unleaded 95 or 98 fuel. It said maintenance costs would be reduced, e.g. no 50 hour oil change on mogas, and also in comparison to the standard 912 there’s no 200h carburettor adjustment or 500h magneto overhaul. These figures must have come from Nogaro.

The major downside is the Rotax’s 2000 hour engine life, as opposed to the Lycoming’s 2,400 plus possible 480 hour extension. The other is the cost of conversion, which wasn’t listed but assumed to be expensive. On the other hand, the conversion is a one-off, and you can deduct the cost of the O235 that would have had to have been bought. It also said that 2,000h certified Rotaxes are in demand from the microlight community, and an end of life Rotax is worth €5,000 compared to €2,000 resale value for a Lycoming.

The potential market was estimated at 460 aircraft in France (I assume the number of 100hp and 120hp DR400s in aéroclub or school use).

I’ve also looked at the website for current information. The cost is €66,000 including taxes for the conversion, and estimated savings are €20-€35 per hour. They’re also working on a 915iS (140hp turbo).

At the other end of the spectrum, you can fit a TP100 turbine to a C172

Edit: video is here