hazek wrote:

God damn I better not need a new one any time soon!

Wait, you have to add the core charge which will only get refunded if your old crankshaft and the rest of important parts are still usable….

So in any case if heavily corroded there is a risk that the OH quote may get out of hand with $15k or more extras.

All turbo engines are much more expensive, probably because they are assumed to be totally shagged by the time they go in for an overhaul, so the average cost is that much higher.

Note also that the exhaust on T engines is assumed to be totally shagged at engine OH, which is another 5 digits.

I found the above when looking at TB21 versus TB20. Not a single TIO-540 (IIRC – there may be 1 owner who was a contrary example) has made TBO without replacing all cylinders.

Thing is people run these engines way too hard and too hot. My partner who was the sole owner until I joined really took care of his engine. We did the compression check, 80 80 80 80 77 80, really. Borescope cylinders, valves looked perfect. No metal in the oil filter. And it’s more than half way towards TBO.

But he flew it below 380° CHT and below 1600° TIT. It’s like cars, you can use yours to drive on the circuit every weekend full throttle close to red line and kill the engine in half a year, or you baby it, always wait for oil to warm up before pushing harder and it can last you 20 years.

I blame the manufacturers, POHs are often marketing material instead of realistic prudent advice. Plus isn’t it nice for them to sell you more spare parts?

hazek wrote:

I blame the manufacturers, POHs are often marketing material instead of realistic prudent advice.

The Mooney TSE comes to mind which needed to get a certified ceiling of 28000 ft to achieve the 252mph the marketing compartement promoted

@Darkfixer what’s wrong with this one?

If you are going for that plane.

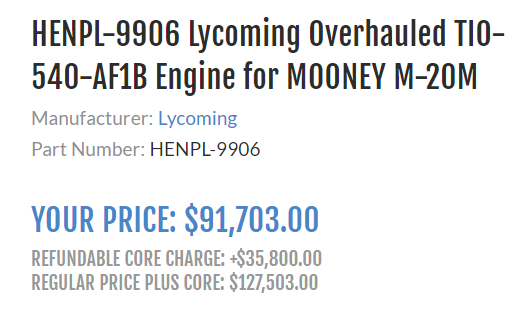

I think you’d probably be better off with an engine overhaul instead of a factory one. Huge price and lead time difference. (For a factory (Lycoming) engine that’s not in stock or on backorder (which is the case for most not so common engines) you’re gonna end up having to wait 2 years.

Also Air Power isn’t always the cheapest option for a factory engine, I’d ask quotes from European distributors, you’d at least save some on shipping costs.

But, if the engine is still far from TBO, maybe you could get the Cylinders repaired or have new ones installed.

You could also ask Lycoming’s advice, luckily their customer service is better than their lead times on parts and engines

It’s not difficult.

I didn’t say it was difficult, just expensive and unnecessary.

Nothing is “necessary” but – read the arguments there and in other threads – the US has a far bigger choice of engine shops on which you can do due diligence than Europe. DD is key in this game and is awfully hard to do for European shops… if you start digging, for almost every shop you hear as many really bad customer reports as you have time to dig up. There are some totally criminal shops in Europe; one fairly centrally located has been known for doing overhauls with a re-spray!

An added dimension is that in certain countries there is a massive loyalty to shops in that country. Well, that’s Europe for you  The situation is pretty unhealthy anyway and is fuelled by dissenters getting beaten up on social media there, and by certain shops offering special deals to valued clients who then post lots on local social media on how great that company is. Bad reports get shared by PM only, plus occassional posts on EuroGA.

The situation is pretty unhealthy anyway and is fuelled by dissenters getting beaten up on social media there, and by certain shops offering special deals to valued clients who then post lots on local social media on how great that company is. Bad reports get shared by PM only, plus occassional posts on EuroGA.

The US is not expensive either because the shipping cost is pretty much compensated by a lower price. Also here. I used that firm twice.

Yes, there certainly are more engine shops in the US, but that doesn’t necessarily mean they are better. In fact; I know there are Americans who even send their engines to a European shop, also not worth the extra cost if you ask me. I’m curious: what do you mean with overhauls with a re-spray and which shop are you referring to here?

I hope you don’t mean just stripping the paint and repainting the engine; that would indeed be criminal and require forging documents, if that were true, that shop should be closed and answer for their crimes in court, that’s not just fraud, that’s playing with peoples lives.

I agree with your statement saying there’s loyalty, or rather chauvinism by people towards a shop located in their own respective country (it’s especially true for France and the UK) but there are other examples across the continent.

Regarding the article you posted I’ve got a few remarks: