Since we are at it again.

Peter wrote:

The cable also needs to be adjusted so that it is “stressed” (compressed, and thus buckling slightly) when the red knob is fully pushed in. That ensures the valve is closed and remains closed

Yep, that was the gear trouble this week. Not finally resolved (will need a permanent solution springy or rubbery) but fixed.

After new pressure switch and new rubber seals in the emergency release valve, i have had my fair share of gear probs.

I had presumed that the pump was not running when the gear dropped in flight. If the gear dropped in spite of the pump running this would mean a major internal leak which would be unlikely to be intermittent. The fault is most likely electrical, especially after it recurred after a winter lay up. Slight corrosion in contacts perhaps?

This in turn can weaken or burn the “up” relay, making it intermittent.

That failure should be evident from the gear gradually dropping and the pump not running. The system is fairly easy to troubleshoot with a voltmeter. If the gear is dropping and there is voltage across the pressure switch, then the switch is faulty. Same with the up relay contact.

Squat switches can make it more complicated, but they aren’t relevant when the gear is up (or supposed to be up) and anyway AIUI not all homebuilts/ULs have squats (some have an airspeed interlock, or nothing).

LeSving wrote:

The Carbon Cub cannot run on other fuel than 100LL for instance.

Not according to the website.

Usually this type of gear is held up by hydraulic pressure only. If the pressure drops a pressure sensing switch will activate the pump. If the gear starts to drop in flight that would indicate that the pump has not started, perhaps a faulty pressure switch or a sticking relay. If there is a leak past a seal in the system (most likely an actuator or the emergency gear release) this can cause the pump to operate very often in flight as the pressure drops. This in turn can weaken or burn the “up” relay, making it intermittent. Therefore I think there are potentially two problems: a leaking seal and intermittent electrics.

Michael, I am not at all surprised that yours uses the same gear pump as mine, but I don’t know how those pumps work internally. Looking at the website I think they are just standard gear pumps i.e. 2 gears meshing together, with various valves added according to how you build the P/N from the various options (for typical landing gear usage you want the pump to be fully blocking in both directions so when the motor stops the fluid cannot flow back).

I doubt you can inspect the internals without a full dismantling. You could try obtaining the overhaul manual for the pump; it might need some subterfuge  OTOH I think the non return valves are just things which screw in from the outside so they might be removable individually.

OTOH I think the non return valves are just things which screw in from the outside so they might be removable individually.

You will definitely need to bleed the system and that’s worth doing anyway, to get fresh fluid in there.

Are you sure the leak is in the pump? It could be in the emergency gear release valve (if you have one) – that’s a classic leakage point. Or in one of the hydraulic actuators.

Hi Peter,

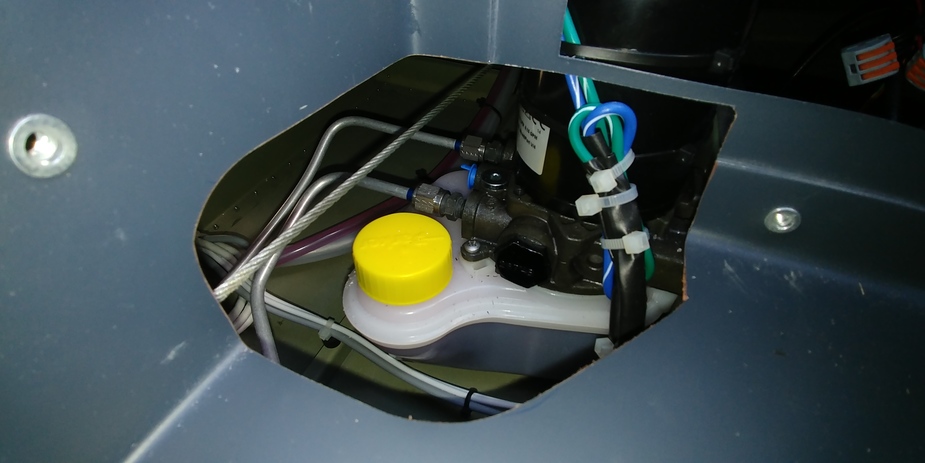

This is a little off topic since it does not specifically concern the TBM, but it might be helpful to everyone dealing with a Parker 108 unit. I own a 2016 Bristell RG “ultralight” and am currently making myself familiar with the whole RG system, obviously based on a Parker 108 unit as well, after recently during several flights my nosewheel and occasionally the main wheels dropped out partially during flight.

The Bristell ist out of warranty and last year I went to my German dealer and we tried to “flush” the whole system by activating the RG on the ground (of course properly elevated of the wings) several times. This really seemed to help as after that the gear stayed under pressure, but now again after the winter break I have the same problem again.

My dealer suggested to open the large hexagonal bolt and check inside for corrosion, there should be a metal ball inside which I can remove with a magnet. Before I do this, I have not seen this procedure in the manual so I would be thankful for any suggestion where the problem might be. I still must find a way to read the sticker on the other side to get the exact model/specs of the unit.

I realised that there are 2 large bolts, is that correct and can I open them safely without having to “bleed” the system (I am still unfamiliar hydraulic systems and the manufacturer is rather slow on answering and I apologize for the question – I am a curious “learning by doing” guy but better ask twice than messing around with the RG)

Thanks for any help,

Michael from Germany

Peter wrote:

Didn’t Lancair sell kits?

The word “kit” is not a very well defined term in the experimental business. “Auxiliary” items such as engine and everything related to the engine, instruments and electric stuff, etc etc is usually not part of the “kit”. A kit is usually just the bare air frame. The reason is that everybody wants their own kind of engine, their own kind of instruments and so on. I don’t know if Lancair delivered those pumps as part of the kit, but I would be more surprised if they did than if they didn’t. Maybe they sold it as a separate kit, or someone else did. For the Sonex line of aircraft, no hardware is included in the kit. Rather ACS sell “hardware kits”, not only for Sonex, but for a whole bunch of others also. That “kit” is basically a long list of different nuts and bolts and other stuff.

The Carbon Cub is different. There every single thing is included, for better or for worse. The Carbon Cub cannot run on other fuel than 100LL for instance. Then there are the “build in 2 weeks” Glasairs and of course the Evolution. But they are not kits at all, they are factory built experimental aircraft with (token) owner participation.

So, a “kit” can be anything from a stack of raw materials and some sketches, to token sanding of a rudder on a factory built aircraft.

Oh yes  Thanks for posting the update.

Thanks for posting the update.

Search here for “Emergency Gear Release Valve”. That valve is easily damaged, either by being partially open (in which case the pressure from the pump can rip the seals) or by being “maintained” by a company which doesn’t know how to do it.

The cable also needs to be adjusted so that it is “stressed” (compressed, and thus buckling slightly) when the red knob is fully pushed in. That ensures the valve is closed and remains closed. Same on the alternate air door under the fuel servo; if that is partially open, even 3mm, you get a big rise in the wear in the soft metals in the engine. I had that…

Update – sometimes (read: rarely, but it happens) problems are not as big as expected/feared.

In my case, it was not the pressure switch or pump, and neither the hydraulic liquid level or a leak.

Apparently, the emergency release valve beneath the panel can develop a leak…

And then you have an internal leak which the pump works against.

That’s what has happened in my case. The emergency valve was not in the release position (for which you have to press a central button first, before pulling it), but at the same time not in the full forward position.

Once fully released and pushed back in again, the system worked perfectly again.

And yes, it all happened on jacks ;-)

Will watch it for some time, of course. But should be all fine again.

How it happened ? No idea – I tend to say “wasn’t me”, but who else ?