All you need is a big shed for your printer…

most of the F1 racear rolloverbar structure are 3d printed Ti sintered

most strenght with a shape and weight otherwise cant be done!

All you need is a big shed for your printer…

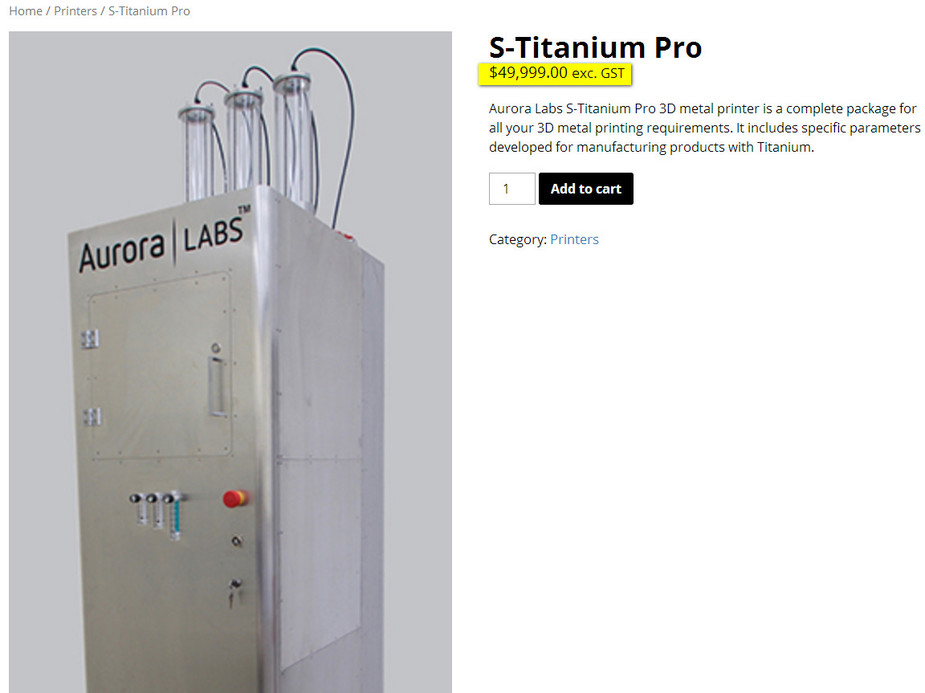

In fact, there is at least one considerably smaller and less expensive machine, S-Titanium Pro by Aurora Labs. It can print iron, stainless steel, inconel, titanium, silumin, bronze, stellite, etc. with ~ 100 µm feature size.

At the price, I will have two so I can knock out these iphone holders faster

BTW, what does one about the sintering? Something like titanium is going to need quite some temperature.

Peter wrote:

At the price, I will have two so I can knock out these iphone holders faster

But that thing is really cheap for a metal printer! With lasers and inert gas and everything… The maximum print size is not really big however (20×20×50cm) but should be sufficient for that iPhone holder. That website is a little bit strange for a commercial product and the specs are very incomplete – nothing about printing speed for example or connections or software or anything. Just the argon gas requirements.

Sofware looks like STL.

GE comes up with meter-size 3D printing machine for aerospace parts.

http://m.aviationweek.com/paris-air-show-2017/size-matters-ge-it-creates-monster-additive-machine

(Is this science or modelling?)

3D – printed car, powered by a 700 HP 2.4l dual-fuel engine.

How GE met 3D:

http://www.gereports.com/mind-meld-ge-3d-printing-visionary-joined-forces/

Back then a tiny nozzle – now you can print a piece as big as 1 m3.

“They moved a few machines to a drab building away from the main campus across Interstate 75 and started experimenting in secret with printing pieces of an old commercial helicopter engine […] The clandestine effort paid off. Within 18 months, the team was able to print half of the machine, reducing 900 separate components to just 14, including one segment that previously had different 300 parts. The printed parts were also 40 percent lighter and 60 percent cheaper. "

“Meanwhile, GE’s engineers had already moved on to the next challenge. A different team decided to create a brand-new advance turboprop engine, or ATP. Using additive manufacturing, they consolidated 855 components into just a dozen parts. The simpler design reduced weight, improved fuel burn by as much as 20 percent and achieved 10 percent more power.”

3D printing combined with 5-axis machining:

Practical application: printed variable scroll turbo with enclosed moving parts for a 1’340 HP engine.