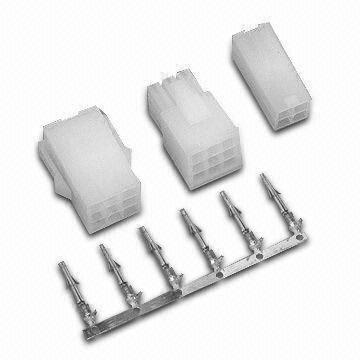

The sort of connectors commonly used in GA

were last used in cars in the days of the famous Vauxhall Viva

and they used to last about as long...

Why do manufacturers continue to use them, 40 years later, on a €300k+ plane?

There cannot be a certification reason.

The car industry wants stuff to be absolutely dirt cheap and they soon moved to the same thing but with o-ring seals around the wires and around the body, so the thing was relatively sealed, and instead of rotting within 5 years it would take 20 years.

If you buy a $3M turboprop then you get these

but they aren't all that pricey relatively - e.g. c. €50/pair. And that's a big one. Smaller ones e.g.

cost about €10 for a pair and are also sealed.

What is suprising is that you can have a €10k avionics refit done and they still throw in the el-cheapo ones.

but they aren't all that pricey relatively

and they aren't all that good, either, but at least they come in olive

But what then IS a good multipole connector? If possible, affordable, too? I am tempted to use the old DB series (DB-9, DB-15, DB-25, DB-37) with crimped-on gold plated contacts. (certification is not an issue for my microlight, low cost and low weight all the more ; 50 quid IS pricey to me!)

The DB connectors are actually OK in a dry situation.

You can get them from ultra cheap and dirty (say €0.05 for a Chinese DB25 in 50k+ volume, so maybe €0.50 from a catalogue) but I wouldn't use those in something important because their corrosion resistance will be close to zero. I use them at work, in 50k+ batches, and they are OK for the office automation stuff we do. They have contacts formed from sheet metal. It's what you find on the back of a modern (crap) printer, for example.

At the opposite end you get heavily gold plated ones for say €5-10 each, and they are fine for aviation use. These have machined contacts.

Actually you can pay even more for fancy DB connectors from e.g. Positronic, which typically use empty shells and crimp contacts, and the contacts can be €2 each, so you can work out the cost of a DB25... these are the ones which use the €800 crimp tools.

But none of these are waterproof so they can't be used where they might be exposed to open airflow e.g. inside-wing connections, which is what my original rant was mainly about. You can get special waterproof DBs but they are sealed only when panel mounted, not when used as inline connectors. For a sealed inline connection you probably need to use something circular, milspec stuff, but there are different grades of "milspec".

How many contacts do you need?

Thank you Peter, you confirmed my impressions. Would you have any suggestion for a grade of quality in between, neither office grade crap nor diamond-machined unobtainium? Vibration resistance seems the most crucial element, making quality of crimp contacts the prime factor.

Number of contacts is less relevant, if one connector pair doesn't do the job then I could use two or even more. At a gut feeling, DB25 should be ample, though.

PS I am far from any degree, engineering least of all, but I should think that open airflow is the least demanding environment for connectors - any moisture that gets in is sure to be blown out..? Dito but less for dirt (which is rare once airborne anyway)? Long periods of disuse are of course detrimental, always and everywhere.

any moisture that gets in is sure to be blown out

Not really. Maybe if you fly in moisture and then finish the flight in dry air - not likely...

I would use properly sealed connectors. The milspec circular ones are usually sealed.

Regards crimping, we discussed this previously. Personally, I can solder well and I prefer to solder, but then it's an absolute must to (a) heatshrink over the soldered pins and joints and (b) properly strain relief protect the wires where they come out of the connector.

Actually (b) is important anyway because if they can flex they will PROB100 break eventually.

The milspec circular ones are usually sealed.

I'm not convinced about these connectors. I have a MS3116 connector in the cockpit. That flimsy bit of rubber neither aligns the pins properly nor does it hold them in place securely. Connecting it is always a hassle and I regularly have to reinsert pins.

They might somewhat work if you build your own cables out of individual wires and mesh or hose but they certainly don't if you use ready made cables.

I'd prefer a good D-Sub (with gold or berrylium bronze plated machined contacts) over the MS3116.

Removed the instrument panel from my own pride and beauty and found no less than four couples of M/F connectors of a type called DS121, the 12-way model. Are these still currently available? What do people think about them?

They are obviously not designed for the aero environment, seeing the spec they carry: 350Volt 10 Amp (but no mention whether that is DC or AC)

They look quite good to me, but they do require soldering which we (well, at least some of us…) prefer to avoid.

For a picture: see http://www.ebay.com/itm/30-PIN-INDUSTRIAL-RECTANGULAR-CONNECTORS-350V-10A-SET-DS121-130-1-01-DS121-130-2-/151127197216 which shows the 30-way model with 3 rows of contacts, mine have 2 rows.

Karel, as far as I know, these connectors are originally from the telecom industry – electromechanical telephone exchanges used them by the thousand. Judging by the fact they occurred on both sides of the Iron Curtain, they were quite popular in their heyday. I seriously doubt they are still being made, but you may be able to find some new old stock.

Update: they seem to be still made in Russia, but only in 5-, 10-, 16- and 30-contact versions. Contact pitch lengthwise is 6.1 mm. They are also available in an IP54 version.

Thanks very much, you are a better www-searcher than myself apparently… They quite look like less-than-brand-new telecom equipment, and as my machine was made in Hungary the Comecon connection is not unexpected. But if they seem reliable enough there is perhaps no real need to replace them.