As shock heating is at least as dangerous as shock cooling, there should be an emergency AD for all engines, that adding power at a rate faster than 25% / 10 seconds is absolutely forbidden.

Therefore most GA airplanes unfortunately can no longer operate from runways shorter than 5 km.

IMHO the reason that is not an issue is that the metal is still too cool at that point and thus retaining its strength.

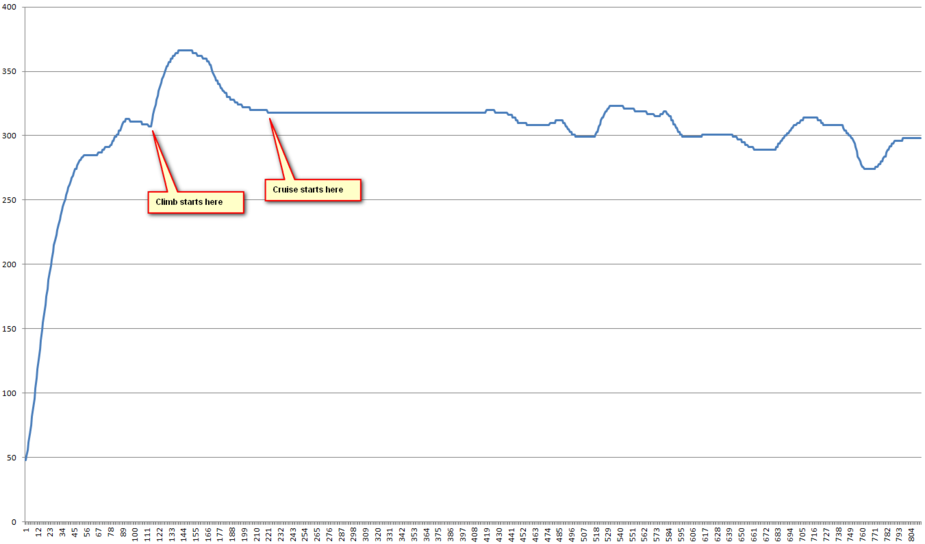

I have just looked at some EDM logs and while the temperature slopes are similar on climb or descent, the climb one is starting at an obviously low temperature e.g.

I can’t find data where the CHT is really high at the end of the cruise portion – probably because I don’t run the engine like that!

The problem is that for obvious reasons (cylinder kits going for ~ 1k each, plus labour) nobody is going to test this

Snoopy wrote:

Shock cooling is a myth

Well, fly the plane you own, the way you like. Fly everyone else’s planes as though care for their engine has some importance.

The referenced article makes a number of unsupported statements, who knows if they are true? I have personally changed cylinders, many of them. Someone suggests that it’s less costly to change cylinders than to operate the engine with care (and take longer in the air) – well, wait ’till you pull a stud installing the next cylinder, and now have to remove and split the engine for crank case repairs – which I have also done!

I worked for a year disassembling and inspecting incoming engines for the engine overhaul shop. Both of the engine shop co owners were pilots, and I flew their planes. They were very clear as to how to operate their engines, and why, including preventing shock cooling by good engine handling techniques! I’ve seen the cracks myself, and with very well instrumented engines, I seen the alarmingly fast temperature changes resulting from rapidly closing the throttle.

I have never had a cracked cylinder in a engine I have owned (3800 hours of operation). I bought a 172 with an O-300, and tore down the engine. Gee, the two rear cylinders were scrapped for cracks.

So suggesting here that pilots need not exercise care for someone else’s engine is unhelpful. Shock cooling is a real risk, and the article which Peter links relates well to experience I was aware of when I flew jumpers. I trained the other pilots as to how to not shock cool, and they went a season with two 185’s, and no cracked cylinders for the first time! Sure, one can go overboard in being cautious, everything in moderation. If you must close the throttle quickly, do the engine a favour, and also slow the plane as much as practical to reduce cooling.

Shock cooling is a mythQuote

Maybe tire and brake wear are myths too? And ride and lock up brakes without worry?

Why make this about me @pilot_dar

Where was I suggesting anything regarding how to treat other’s planes „here“? I posted an article. That’s all.

I’m not as experienced as you are by far regarding engines, but I’m trying to learn more and that involves reading deeper into things and challenge (lots of the OWT) I was taught in basic training.

I welcome any articles or personal anecdotes you might have regarding shock cooling.

The question is usually vague,

- How much of EDM erratic and fast moving EGTs & CHTs pass-through metal as elasticity? and as plasticity?

- How much of join thermal & mechanical load lead to crack creation and propagation?

- How much metal plasticity appears during an eye inspection of cylinders?

- How much of what eyes see matters to have an engine failure in-flight?

It definitely matters, the question how much of it gets through? and how much the pilot can help on his side  ?

?

I know how many times my gliding club replaced their tug aircraft cylinders but not sure if that relates to thermal shock? or takeoff/landing power cycles? but their outcomes are not pretty

Snoopy wrote:

I welcome any articles or personal anecdotes you might have regarding shock cooling.

Probably not related but my previous job was modelling of 3D crack propagation in Nickel (Inco 625) and Titanium (Ti‐6Al) supper-alloys, and at the end of the day we had to come up with estimates of jet engines lifespan and future inspection dates (aim is to get engine specific inspection approval rather than “regular intervals”), you throw cracked fans into the engine (A320/CFM56 and Rafale/M88), you get thermo-mecahnical load data after the last inspection, do simulations and you open the engine for inspection and you compare to where you think it should be

I think those who don’t believe in shock cooling think like military, the goal is not to preserve the engine but rather use it to max/min loads, if it has a problem it will tell you, you inspect it, you fix it and if unhappy buy a new one

The problem with GA engines, 1/ first it will not tell you until it’s too late, most will not know about any cracked cylinder until it cracks and 2/ second those who “don’t believe in shock load” will still go after the cheapest inspection framework rather than making a tailored heavy maintenance program…

Snoopy wrote:

Why make this about me @pilot_dar

Where was I suggesting anything regarding how to treat other’s planes „here“? I posted an article. That’s all.

The answer to that question is that sure, there are all sorts of articles “out there”, which may be posted/linked etc. The fact that it can be found, does not in and of itself make it valued reading, and perhaps promoting it in conflict with conservative opinions does not serve the greater interest. In “the old days”, articles were typically printed in magazines, and thus subject to some qualified review. I think that today’s freedom to publish – here, for example, allows less authoritative information to appear to be credible. Yes, AvWeb, has some credibility, and, having met Paul Bertorelli, I am generally supportive of what they “publish”. That article (not written by Paul), no.

I have a lot of experience with “other ways” to do things in airplanes, which I do not post at all. I’m concerned that others might read it, interpret it, perhaps differently, or in a different context, and an unfortunate outcome could result. A few too many times, a wise old pilot has said: “Pilot DAR, gee, I know you can do that, but someone else will see you doing it, and try it themselves. They don’t know what you’re doing to mitigate risk, and they may have a problem, how would you feel if that happened?”

My first exposure to concern with shock cooling (as it was never mentioned during my PPL training) was when I was invited to fly Piper Turbo Aztecs. There were three extremely well cared for Aztecs in the fleet, and the rule was when planning descent (particularly in the winter), a power reduction of 1" of MP per minute, use the cowl flaps effectively, and watch the CHT’s. This was as much planning for passenger comfort, as shock cooling prevention. A well planned decent prevents one having to dive for the ground, and upsetting passenger’s ears. I find 1" per minute MP to be conservative, though I have no recollection of them ever changing a cylinder either. When they sold an Aztec, and bought the Cheyenne, one of the conversion training points was “hey, it’s turbine, so shock cooling is not a risk any more! It’s pressurized, so with a well planned descent, you can just point it down, neither the engines, nor the passengers will mind!”.

I started flying jumpers in 185’s decades later, and with lots of dirty hands engine shop experience behind me, when the operator complained about frequent cracked cylinders, I did some mentoring of their pilots, and it appeared that the problem was reduced, if not eliminated.

The problem with cylinder cracking, is that unless there is only one pilot who flies the plane, it’s hard to know who to hold to account for damage found later. In fairness, even the pilot might not realized that in one rapid motion of the throttle, they’d done $6,000 damage to the engine. So training should be broad through all pilots, with a consistent message of conservatism. When I flew the company Cessna 310 for a year, I was its only pilot, so I knew that if there was a problem, I would be accountable for it. It was years later that I learned enough about the vulnerable alternator drive couplings to realize that it had been my poor engine/electrical system handling technique which had required them to be changed. I didn’t know then, as I’d not been trained that, and the company didn’t know either, so they didn’t blame me – but I was responsible, and could have handled the plane better to prevent that premature failure.

Sure, cylinders are designed to be changed, and they are not horribly expensive, compared to some engine accessories. But, the labour to change a cylinder, and the risk or ruining an exhaust or cylinder base stud makes cylinder removal very undesirable. I’d owned my 150 only a couple of months when a stuck exhaust valve meant I had to remove a cylinder. Sure enough, while reinstalling, it, and (having been warned) using a torque wrench, I pulled a stud – worse, a through stud. Now I had the cost to remove the engine, and split the case to repair that. There was no doubt that the cylinder had to be changed, so it was inevitable in that case. but I sure became motivated to do whatever I could to prevent needing to change cylinders (and I helicoiled all the studs in that case, just to be sure for next time).

When I flight test a plane, there are some things which require sudden power changes. I just cringe, and do it as gently as possible to still meet the test point. So, I extra like flight testing turbine planes, they are less sensitive.

On this topic, as any other, I will post based upon my experience, and the properly conservative way I know things should be done for safety, and mechanical sympathy with the machine. When someone reads my post, they can agree or not, but should they choose to follow what I have posted, they will be following the path of less risk, a little less adventure, and considerably less to worry about for maintenance!

Unfortunately there is a certain tendency with most people, to regard anecdotes that support ones basic belief as facts while as the same time asking people who tell anecdotes that oppose their beliefs for “the real facts”.

(Sad) truth is: As SEP-Engines are almost never run in a tightly controlled environment from first to last hour of operation, there simply are no facts to prove any long term impact of specific operating practice on engine life. Not for shock cooling, not for oil additives, not for single vs. multigrade oil, not for …

Even the most religious promoters of the shock cooling gospel have to admit, that they do many things with their engine differently from the average Joe (like oil changes, warm up, etc.) and therefore will never be able to provide a fact base on the question what the individual effect of shock cooling might or might not be.

Malibuflyer wrote:

tendency with most people, to regard anecdotes that support ones basic belief as facts while as the same time

That is indeed part of human nature, but there is another tendency, found on this website more than many other places, to search openmindedly for aviation wisdom and provide valuable facts.

“(Sad) truth is: As SEP-Engines are almost never run in a tightly controlled environment from first to last hour of operation, there simply are no facts to prove any long term impact of specific operating practice on engine life. Not for shock cooling, not for oil additives, not for single vs. multigrade oil, not for …”

It is mostly common sense, few descriptif facts and personal experiences rather than predictive science

The Lyco/Conti manufacturers are not keen on gathering specific operating envirement & engine inspection data, they just want a 2000h TBO signoff for everybody