That is fantastic but airfield-political factors prevent this for probably the vast majority of owners.

I once started building an “engine protector” which would hang off the exhaust pipe and blow dry air up it. The battery, driving a tiny fan (from a PC video card), would last about a week and same for the 0.5kg silica gel bag inside the contraption. But as I fly every week and use Camguard I didn’t bother finishing it.

Here’s some data. I keep 0.5kg of silica gel in my plane. The single bag normally lives in the luggage compartment and I change it once a week. This period was established by weighing the bags – see post #8 above.

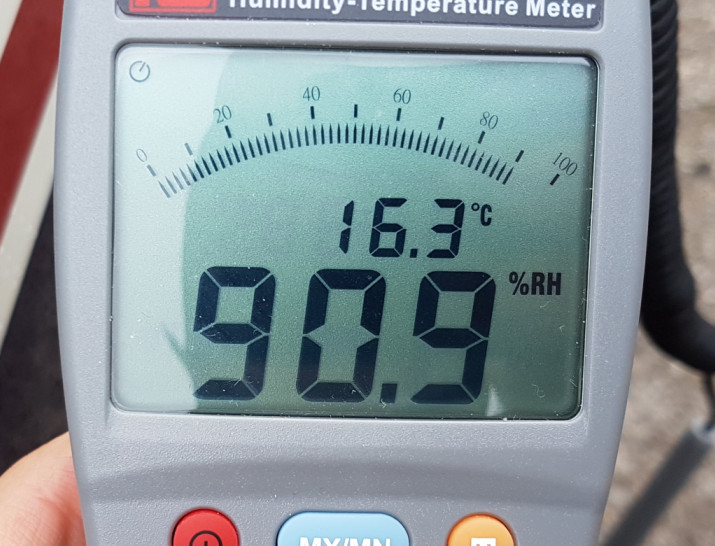

Today, very light drizzle, outside the aircraft:

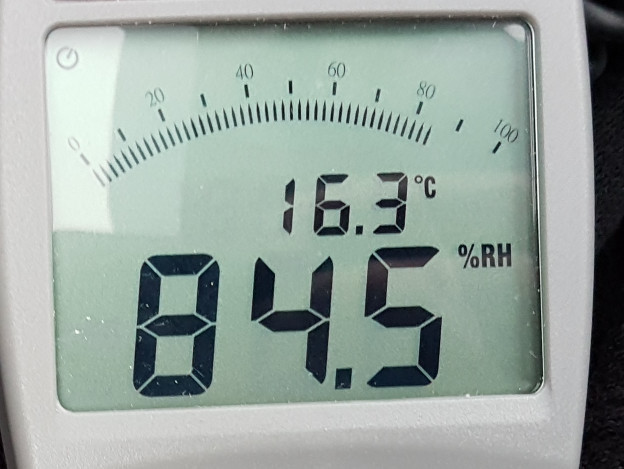

Inside the aircraft:

In the luggage compartment

In the front seat

I can’t explain the variation between the last two. It could be there is a draught into the back of the plane which replenishes the water vapour.

This result – an RH drop of 10% – is extremely good because you won’t get any condensation at 90% RH.

Reducing relative humidity at 16 degrees C from 100% to 90% could be done by taking away 10% of the humidity as descibed here. The same 90% could be achieved by raising the temperature by only 1,7 degrees C. I have seen owners having a 40W light bulb lit below the avionics during winter, and I wonder if that is not enough to heat up the area by a couple degrees. I have considered doing that since it seems a simpler solution, but no-one has mentioned it here. What’s the catch? Paying for the electricity?

Can calcium chloride solution be oven-dried back to anhydrous calcium chloride?

Anyway it doesn’t seem suitable for an aeroplane due to corrosion and inevitability of a spill, eventually.

Maoraigh wrote:

Can calcium chloride solution be oven-dried back to anhydrous calcium chloride?

You can do it, but it’s not easy – you have to heat it to about 250°C, which is above its melting temperature, then cool it down, break it into lumps and grind them into powder – all that in a dry atmosphere. It’s not entirelly inert, either, and airborne powder can irritate your skin, eyes and lungs. Bottom line: use silica gel instead. By the way, before drying the silica gel, you can treat it with a solution of cobalt chloride, which will provide a very clear indication of its moisture content: it will be bright blue when dry and almost colourless (very pale pink) when moisture-saturated. You only need to do this cobalt chloride treatment once, it stays in the granules forever.

0.5kg of silica gel is under €10 so this is a good solution. I normally buy the bags 10 at a time and they last for several years. In fact the stitching breaks up before the material ceases to work.

Reducing relative humidity at 16 degrees C from 100% to 90% could be done by taking away 10% of the humidity as descibed here. The same 90% could be achieved by raising the temperature by only 1,7 degrees C. I have seen owners having a 40W light bulb lit below the avionics during winter, and I wonder if that is not enough to heat up the area by a couple degrees. I have considered doing that since it seems a simpler solution, but no-one has mentioned it here. What’s the catch? Paying for the electricity?

Yes this is very true. It is why the RH is an unheated hangar is not going to normally reach 100% – because even under an overcast there is usually just a little bit of solar radiation (IR) warming up the structure, maybe 1C. At night the gain will be zero but there is usually a bit of inertia from the previous day. Note from the above pics the delta T in the cockpit appears to be only 0.1C above ambient, but I think that is a fluke: I took those readings around 9am, after the plane was standing outside overnight, at something like +13C, and while the ambient was rising as the day started, the cockpit lagged behind.

The biggest problem I see with warming the cockpit is the usual one of airport politics: you aren’t allowed to connect power to the plane. I know many here will post they can do exactly that (and have a crew room with a waitress serving hot choc and coffee and mocha  ) but from what I see the reality for most is that they can’t do it. A battery is not a solution because it won’t last; a car battery will deliver 40W for only about 15hrs.

) but from what I see the reality for most is that they can’t do it. A battery is not a solution because it won’t last; a car battery will deliver 40W for only about 15hrs.

Otherwise, warming the cockpit is much better than absorbing the moisture because the latter method generates a reduction in the partial pressure of water vapour and thus draws in water vapour through all the orifices (unpressurised cockpit) so the silica gel has to be replaced regularly, whereas a heat source will maintain the humidity equilibrium for ever.

Not wanting to rain on anyone’s parade (!) but how sure are you that condensation is due to exchange of outside air? My PA-28 had a long history of condensation problems which were only finally fixed by actually using the cover which had been languishing in the storeroom since I bought the plane.

It turned out that the condensation was caused by minor leaks wetting the carpet which then exhaled water vapour permanently. An electric dehumidifier would will up its 1l tank in a few days, but there was a limitless source of water right there inside the plane. Oh yes, changing all the windows and the screens didn’t fix it either. One point of entry is right along the aft fuselage side where Mr Piper had managed to have a lap riveted seam the wrong way up, channelling literally gallons of water into the inaccessible area under the load bay over the winter. Sealing this offending seam fixed the leaks that the cover couldn’t reach.

And regarding electric dehumidifiers, don’t be tempted to run the cable through the DV window. A slight tug leads to a cracked plexiglass!

I have an electric oil radiator inside the aircraft. Raising the temperature is the most effective means. It does require 230V at the aircraft which I fortunately have.

Don’t use electric heaters with a fan, those are a major fire hazard.