From here

Peter wrote:

However, a GNS430 is an emitter too; it transmits on VHF. So how can an A&P change the battery? And if he did the radio tech course then he doesn’t need to be an A&P – is that correct?

An A&P would need to be a radio tech but a simple radio tech cannot legally work on an aircraft parts or systems.

The “CMM” argument is a valid one since the FAA spells it out very clearly in FAR 65.81 – “General privileges and limitations.”

(a) A certificated mechanic may perform or supervise the maintenance, preventive maintenance or alteration of an aircraft or appliance, or a part thereof, for which he is rated (but excluding major repairs to, and major alterations of, propellers, and any repair to, or alteration of, instruments), and may perform additional duties in accordance with §§65.85, 65.87, and 65.95.

However, he may not supervise the maintenance, preventive maintenance, or alteration of, or approve and return to service, any aircraft or appliance, or part thereof, for which he is rated unless he has satisfactorily performed the work concerned at an earlier date. If he has not so performed that work at an earlier date, he may show his ability to do it by performing it to the satisfaction of the Administrator or under the direct supervision of a certificated and appropriately rated mechanic, or a certificated repairman, who has had previous experience in the specific operation concerned.

(b) A certificated mechanic may not exercise the privileges of his certificate and rating unless he understands the current instructions of the manufacturer, and the maintenance manuals, for the specific operation concerned.

I find the obviously intentional use of the word ‘understands’ (current documentation etc) as opposed to a more constraining requirement to be interesting. I think that provides some level of operational leeway to the A&P, as per real world practice.

The Q is whether, taking the very common example of the ATP $1000/year CD MM subscription (that’s $1000 per aircraft type, broadly speaking!), is it mandatory to be in possession of the latest CD (i.e. January 2017) even if it can be shown that no edits were made since a date in 2005?

The EASA-land position which I commonly see stated in the UK is that you are required to have the subscription in order to work on the said type. This is widely disregarded however on the grounds of being nonsense, not least because many types are too rare to make it worth paying the CD subscription.

One position I see in the USA is that the mfg MM is mandatory and in the latest dated form. That is just one guy however. The only scenario where I have seen this operated was here in the UK where an FAA 145 company would not maintain an N-reg which was not on their list, which probably made sense given the tighter regs on Repair Stations. They could have worked around this by getting an A&P to work freelance under their roof and a freelance A&P/IA also under their roof to sign it off.

Parks Air College apparently built eight Detroit-Parks P-2A Speedsters in 1929. They are FAA certified aircraft today. Fans of Richard Bach’s books may remember the type being used for selling rides. Do you think the MMs are available on CD? The design was sold to Ryan Aeronautical, a company sold to Northrop Grumman maybe 10 years ago. Somebody should ask NG what they have available

Obviously A&Ps will try to get all the data they can, but they do not always have the most current MM on hand, assuming such a thing ever existed. I don’t believe they are required to by the FAA regulation Michael quoted, they only need to “understand” whatever data may exist.

Peter wrote:

The only scenario where I have seen this operated was here in the UK where an FAA 145 company would not maintain an N-reg which was not on their list, which probably made sense given the tighter regs on Repair Stations. They could have worked around this by getting an A&P to work freelance under their roof and a freelance A&P/IA also under their roof to sign it off.

An EASA company with FAA 145 rating will normally have exactly the same scope on their FAA repair station rating as on their EASA approval.

The only time this isn’t the case is per Section A appendix 7 of the MAG where, for example you need to conduct FAR 91-411/413 checks on an aircraft that can’t be on your EASA Part 145 such as the Piper PA18, or there is a minor difference in component ratings.

From the MAG:

There are some occasions when the EASA rating may exceed the

FAA rating; in these cases, the FAA will add an additional limited

rating to cover the extent of the EASA rating. Example: an EASA

A1 airframe rating also allows some limited power plant

maintenance. The FAA will issue a limited power plant rating along

with the Airframe rating in order to allow the AMO the same

privileges as the EASA rating. The AMO should verify that the FAA

rating issued covers the appropriate functions under the EASA

rating.

For cases where the FAA specialized services ratings are not

approved under the EASA rating system, the FAA will amend the

OpSpecs to reflect those specialized services under the limited

ratings detailing the scope and application of the work performed.

For test and inspections of ATC transponder, altimeters, and

altitude reporting equipment installed on U.S.-registered aircraft in

accordance with 14 CFR part 91 (§ 91.411 and § 91.413), for which

the AMO does not hold the equivalent EASA Part-145 airframe

ratings (e.g., A1, A2, etc.), the FAA will issue or amend the 14 CFR

part 145 OpSpec A003 to include these aircraft under the FAA’s

appropriate ratings as long as the AMO holds an EASA rating for

such equipment (C-3, C-13)Bold

The FAA repair station regs aren’t any tighter – the EASA/FAA repair station works to it’s EASA Part 145 MOE and its attached FAA supplement.

Peter wrote:

One position I see in the USA is that the mfg MM is mandatory and in the latest dated form.

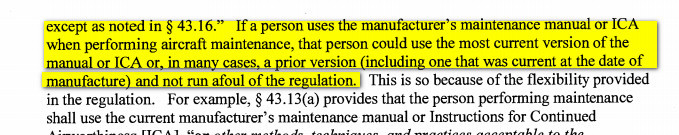

That very much depends. See this 2010 FAA General Counsel letter for one interpretation. There are numerous other interpretations on this topic. 2010 FAA General Counsel interpretation

The reality here, and possibly also in the US although to a lesser extent (because getting a fresh FAA 145 in Europe has been historically hard*), is that most piston maintenance is done by non-145 firms.

The requirement for the data is quite relevant in the non-145 scenario.

When I used to use companies to maintain mine (G-reg initially and later N-reg) I would give them a copy of the Feb 2006 MM+IPC CD.

That data, for the TB range, now appears on the TB user group site (accessible to admin-approved people only) and the admin makes the point that nobody should work on TBs unless they have access to this data, and invites A&Ps (it’s mainly a US site) to join the site so they can legally work on a TB.

The Socata scenario is made more complicated by

)

)Of course I do have the latest diagrams (a helpful person fedexed me the whole lot, in ring binder form!) but the wider point is that if this “latest data” requirement was taken literally, almost no avionics shop, US or Europe or anywhere, could legally do anything on a TB. Yet, they do, so self evidently this cannot be literally true, and if it was, it could not be enforced without ending a lot of industry capability. Let’s face it, most avionics shops have to deal with aircraft without much (or any) wiring info.

* To get a FAA 145 company set up here in Europe you needed “good US connections” (e.g. a Cessna Citation dealer could get it) or you bought an existing company which had it (even if the company was defunct).

Thanks for posting that, NCYankee.

On my reading, this paragraph is applicable to the usual sort of A&P/IA maintenance:

i.e. the latest available data is not required.

Thereafter, the FAA opinion moves on to “repair stations” which I see is a different thing, and on my reading these do need to have the latest data (if they do the work under their 145 umbrella, which they don’t have to do as I mentioned above). But most GA (all of piston and SET GA) does not need a 145 company anyway (apart from the 2-yearly FAA static system checks).

In fact which planes need a 145 company? A couple of past threads are here and here

How about the EASA Part M situation?

Probably more to the point is that the “standard” depends very much on :

- The operating environment, ex. Part 91, 121, 135, etc;

- The type of aircraft, ex. vintage CAR 3, Part 23, piston Vs turbine, >12,000lbs. etc.;

- The actual availability of said documentation .

- The complexity of the task and/or component at hand.

Further, ss NCYankee ’s document suggests, this is a grey area and thus subject to interpretations.