I just received this from a colleague in our aero club, which is good news. In Sweden we’ve had Hjelmco 91/96UL fuel for many years and I guess that a lot of aircraft only fly on this fuel.

"

This Service Letter identifies extended maintenance intervals as benefits of routine exclusive use of approved unleaded fuels identified in the latest revision of Service Instruction No. SI-1070 for Lycoming engine models.

Continued and consistent use of unleaded fuel decreases the risk of lead fouling of spark plugs and contamination of engine oil with leaded combustion byproducts. As a result, engines continuously operated on unleaded fuel could realize the following advantages:

* Extended maintenance intervals for spark plug rotation/replacement

* Extended operating hours between oil change

"

Unfortunately, even one partial fill-up with 100LL cancels this change.

martin-esmi wrote:

Unfortunately, even one partial fill-up with 100LL cancels this change.

Which will make the extended interval near worthless IMO — at least for aircraft that is use for any kind of travelling. While I would guess that 91/96UL is the most commonly found fuel on club airfields in Sweden, not many commercial airports has it, so if you leave your home base it is difficult to avoid filling up with 100LL at some point.

This looks really interesting as it may establish a formal 100hr service interval and thus save owners the £600 (TB20 price) of the 50hr service done by a company, but it doesn’t avoid the 50hr service because AFAICS the oil filter still has to be changed

One positive is that you may be able to change the oil filter with just the top cowling removed, and apart from the wirelocking it is a dead easy job,

The negative is that you don’t get an opportunity to eyeball the engine area in between Annuals and there have apparently been accidents where such an opportunity might have saved things. In one case a hose bracket failed on a Cessna 200-something and the hose fireproofing eventually burned through (it rested against an exhaust pipe) resulting in a total loss of oil.

However the bigger Lycos all AFAIK have the oil suction screen, so the 4 month time limit comes in anyway…

Peter wrote:

This looks really interesting as it may establish a formal 100hr service interval and thus save owners the £600 (TB20 price) of the 50hr service done by a company, but it doesn’t avoid the 50hr service because AFAICS the oil filter still has to be changed

That’s how I read it first. But on second reading, I don’t think that’s the case.

I now read it as:

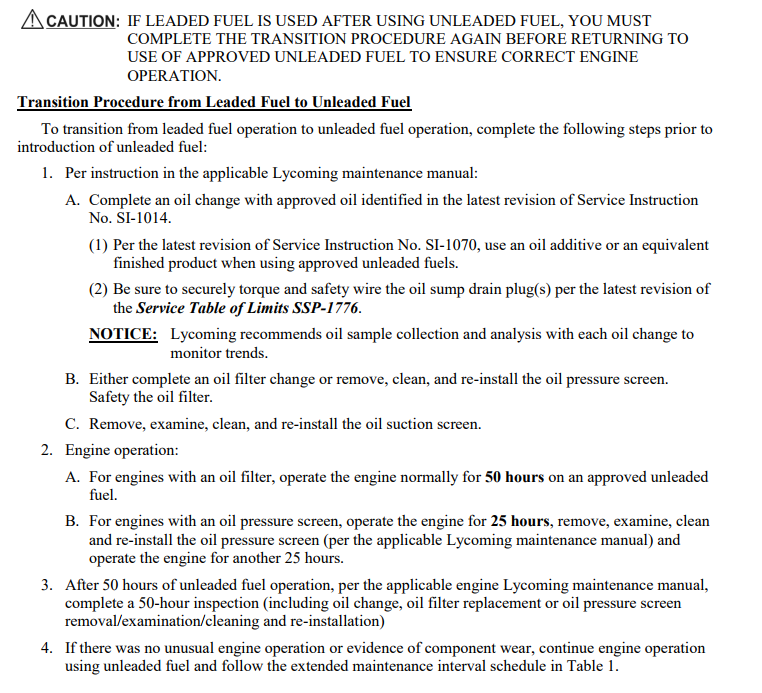

Hour 0 do a service and cease using leaded fuel.

Hour 50 do a filter change

Hour 100 do a 100 hour service

Thereafter every 100 hours a service.

So the 50 hour filter change is only after initially changing over to unleaded, not every 50 hours thereafter.

What is it that makes the oil go so dark by the time the 50hr point arrives?

Also, based on my own experience I don’t understand how extending oil life to 100hrs will work, just because there is no lead in the fuel.

I wonder if @ed2 has any comments?

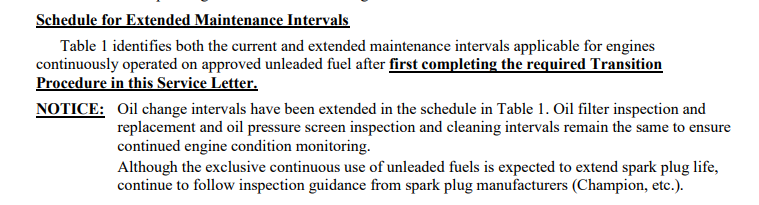

In order to truly understand we need to read two documents. Service Bulletin 480 and Service letter SL270.

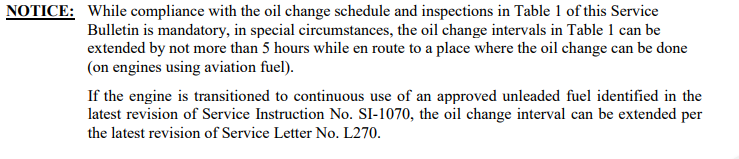

In SB480 there is a notice when transitioning an engine to an approved unleaded fuel:

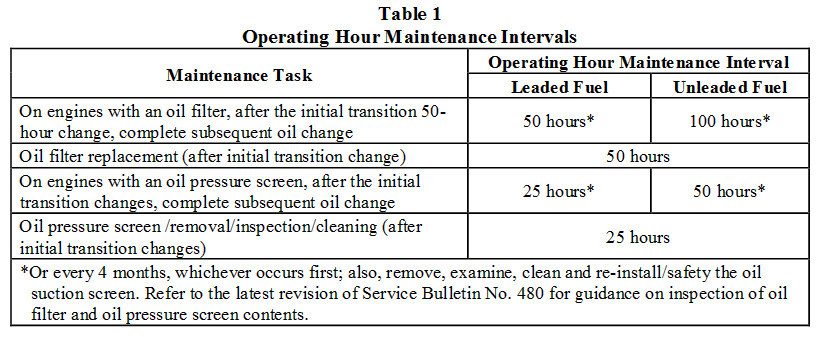

As Peter posted earlier in the thread, table 1 gives the maintenance intervals, but what is crucial about this is the instructions prior the table:

This table is only applicable if you first complete the required transition procedure:

So to wrap this up, when transitioning to unleaded fuel, you must do an oil change and service when the physical fuel transition takes place. 50 hours later you do another oil change and service. If no unusual findings are found, you then can follow the extended maintenance intervals. The oil filter must be replaced every 50 hours or 4 months and the pressure screen must be inspected every 50 hours. The oil is every 100 hours. So yes the oil can be extended to 100 hours but all other service items remain the same time frame.

oil darkens due to heat, contaminates and additives in the oil itself. Consistent use of unleaded fuel reduces the risk of lead fouling on the plugs and contaminants in the oil due to lead byproducts from combustion. Less lead means better oil and better spark plugs.

With a Continental O200 on mogas, and a motor-type screw-on filter, which we change every 50 hours, we do an oil change (Aeroshell 15W50) every 25 hours. This regime is getting people over 3000 trouble-free hours.

Compared to car oil, aviation oil is cheap. We do our own checks, so labour is not charged. If paying for labour, the oil cost saving over 100 hours must be a small percentage.

I think there are factors here which go well beyond the time or cost of an oil change or the oil filter change interval:

They won’t end up in the oil filter…

They won’t end up in the oil filter…I have often wondered what the Major/Minor mod status would be to fit an inspection-size door into the lower cowling (like the one in the top cowling for the dipstick) so oil could be drained without all that dismatling. We have usually had great difficulties here getting comments on a likely status of a mod (the FAA gave somebody a bollocking for posting on here, for example, and he then virtually disappeared) but if anyone can come up with something concrete e.g. some precedent, I will start a new thread on it (or they can, of course). Obviously it is possible via a Field Approval (N-reg) but the real target would be a Minor Alteration. But as I say above this would not give an opportunity to inspect the engine compartment, unless one does that with an endoscope.

Oil changes are key to a well maintained aircraft. It allows mechanics to inspect the powerplant and detect if there are any signs of trouble. Lycomings Service letter only adds life to the oil filter, so I can’t see any real cost saving by doing it.

There are ways to do an oil change in a timely manner without removing all the cowling. By using Custom metal trophs and tubes that feed through the openings in the bottoms of the cowling. It’s not easy but can be done. Any shop should be able to do an oil change in 3-4 hours even if they have to remove the cowlings.

The inspection panel can be a great idea. Doing a From 337 for the alteration wouldn’t be a big deal. The hard part is to find the substantiated data for the FAA. If no one has ever done it before, getting the right FAA inspector to sign off on it will take time to get the data he wants. But once you have a baseline of approvals, the future ones will be a lot easier. You could look into NORSEE. The FAA is really pushing for new technology and safety measures into GA. The experimental scene here in the US is killing the Type Certificated aircraft. As everyone here could attest to, making mods and adding new technology to your aircraft is a huge benefit. If we could find a way to word the installation of this panel as a safety measure, its worth a shot. Maybe a shot in the dark but hey, you never know.

Peter wrote:

On most GA types, a lot of dismantling is needed to change the oil

You’re a victim of the extremely service unfriendly TB aircraft. The situation is much better for the majority of aircraft with little to no dismantling required. I can do an oil change and filter change in 30 minutes without help. All I have to do is remove one side of the cowling by opening a few cam locks, insert a hose through a cowl flap and let it run. Form-a-funnel™ under the oil filter, remove strainer, all easily accessible and done.

Peter wrote:

if done by a company, which is unavoidably the case for most GA cases

Why? I know a lot of pilots (myself included) who do it entirely on their own. It does not require any special skills and it is great opportunity to inspect the engine.