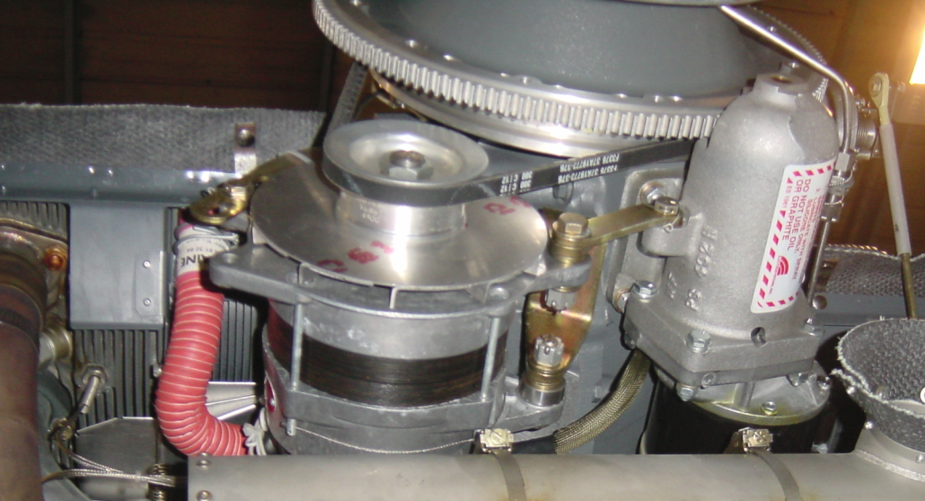

This is quite a common layout on engines especially the Conti 550 series

Who would expect electrics to last for long when exposed like that?

Look at that white rubber terminal shroud. It is open at the base – basically it is totally useless; it was fitted because somebody was told to fit it, not because it does anything useful – and in any rain it will fill up with water which will get forced down that cable. That is the field connection; the output is the thick white cable with the red sleeve.

In fact any rain will fill up the whole alternator with water.

Engineers were obviously more worried about cooling on this one.

Why are you so worried about a bit of rain on the alternator? Have you heard of a failure being triggered by it?

The white cap is obviously not properly positioned. A bit of water down the wire should not cause it to short to ground: it would need to be basically submerged.

Of course this level of environmental exposure will cause some corrosion in the long run, but you are supposed to do annual inspections and remove it at 500hrs anyway, which should take care of it.

Last, IIRC most of these Cirri have the second alternator at the back of the engine where it is warmer but more protected from the elements.

My bad: ALT 2 is also fwd of the engine , but on the lh side, at lest on perspective aircraft.

Sure, high current electrics work even when fully submerged, but it doesn’t do them any good.

The water will corrode everything inside. Brushes (which are spring loaded with quite small springs), slip rings, the rectifier assembly… the whole lot. The cable has crimp terminations which will eventually perish due to being filled with water, which will be forced down the length of the cable all the way to the other end, between the strands (I have seen that process work; it’s quite impressive).

I don’t know the cost of this alternator but mine costs about 1k.

The cable has crimp terminations which will eventually perish due to being filled with water, which will be forced down the length of the cable all the way to the other end, between the strands (I have seen that process work; it’s quite impressive).

Ah, you mean inside the insulator…is that not avoided easily with some terminal grease, which effectively seals the ends (as long as the protective cap is in place to keep it there)? In any case I thought this was more of a problem for aluminum (vs copper) cables.

This isn’t just the SR22; loads of aircraft types have this stuff totally exposed so it fills up with water in any heavy rain.

Yet, it is clearly not difficult to hide it. This is the IO540 / TB20 installation – pic from underneath. You can see the cooling pipe to the alternator

Good business for alternator replacements

Peter wrote:

I don’t know the cost of this alternator but mine costs about 1k.

Cirrus Alternator:

BC410-1 / new / EUR 3.920,00

BC410-1 / O/H Ex / EUR 1.495,00 (+ Core USD 1.000,00)

Good luck with getting the core discount in Europe  It generally works only if there are overhaul facilities in Europe and for most US aircraft parts, there aren’t. Been around this block a few times…

It generally works only if there are overhaul facilities in Europe and for most US aircraft parts, there aren’t. Been around this block a few times…

This quote is from the 145 shop at my field and you do get the 1000 usd cover back.

Snoopy wrote:

you do get the 1000 usd cover back.

Yup, it takes a couple of months, but unless your core is totally banged up you get it back.