Yes indeed; if the UK welder (who is CAA approved) cannot do it then I will DHL it to the US. Acorn is one of 2 or 3 well known firms.

One guy from Acorn has however stated they don’t like Inconel, for some reason… Could be that it greatly reduces the amount of business.

Peter wrote:

Could be that it greatly reduces the amount of business.

Maybe, maybe because it is more difficult to machine smooth after welding or because the welding rods are three times the price?

It is difficult to tell how long it will take to propagate, but based on the fact that most crack-prone exhausts on turboe’d aircraft are happy with 50-hr inspection intervals, including those subjected to AD’s, then I’d say 50 hrs is a reasonably safe crack propagation interval in an otherwise sound exhaust.

That is 50hrs from just undetectable to bad enough to be detectable but not so bad as to cause a major safety concern.

In your case we would need to know how long ago it transitioned out of barely detectable, but being NA, I’d say 50 hrs from detection with zero leakage is reasonably safe.

A different matter is whether you should fly on once you know the problem is there. For that you should formally use AMM or SM serviceability criteria. In my (TC’d) case it is zero cracks allowed.

The weld should not be ground smooth.

Anybody competent can weld the exhaust pipe and on an N-registered plane any A&P can sign it off. There are doubtless a lot of competent inconel welders in the UK.

Silvaire wrote:

The weld should not be ground smooth.

…on the inside it should: it must not be left with rough protrusions. On the outside I agree with you.

I got this welded up.

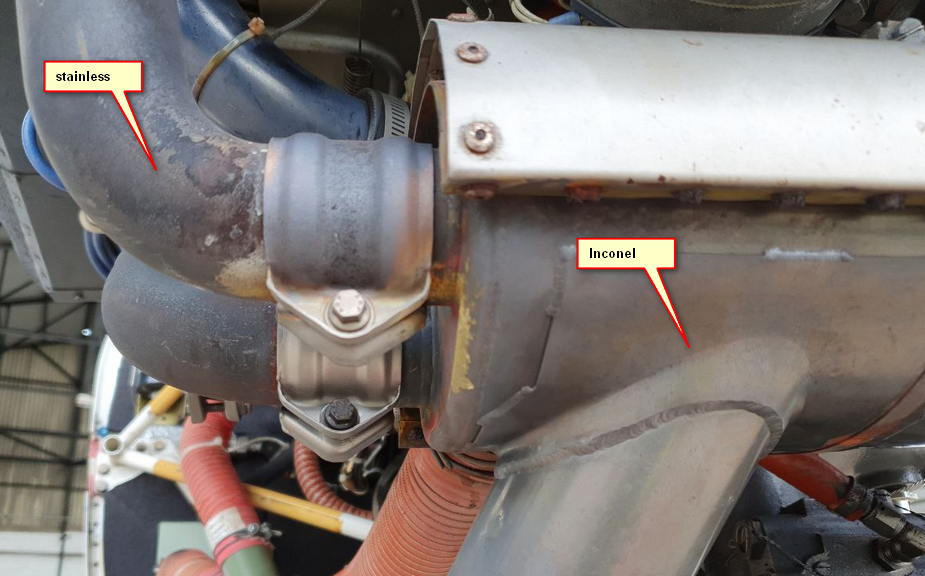

The amazing thing is that it is stainless steel. Socata heavily promoted the GT aircraft as having Inconel exhaust but clearly this is not the case…

The guy reckons I should get the exhaust replaced at some point, especially that section.

All done

The verdict is that the “whole exhaust on a GT is inconel” is a con. This has been repeated by Socata reps on their US owners group many times (I have a number of screenshots).

Well, maybe it is not a complete con and some “very late” GTs are actually all Inconel but mine, 2121, and fairly close to end of all piston production in ~2002, is definitely stainless on the pipes, and the silencer (muffler) is Inconel.

Not bad condition given ~2500hrs airborne time, all at peak EGT.

Here is an update:

Firstly, the whole Socata exhaust system is stainless steel, not inconel, so the whole “GTs have an inconel exhaust” is a total Socata lie which their people repeated countless times over the 20 years I’ve had the plane. I asked Socata about this and never got a reply.

The other bit is that the welded up exhaust pipe lasted 1.5 years.

Unfortunately, I wasn’t proactive on this and didn’t use that time to get hold of a proper spare, which is what I usually do. And, on the last Annual, Dec 2022, a lump was found:

and by that time the end which goes into the muffler didn’t look too great either

I embarked on a search for a replacement pipe, mentioned here, which took a lot longer than expected. No European contact got anywhere near delivering. Specialist aviation welders were basically not interested, one UK company was but at a price of about 4k, Socata wanted 2.5k for theirs but with an indeterminate lead time of “maybe Feb or March” which, knowing Socata, means very little. In the US, there is Acorn and AWI (both now same company) and mentioned here. Acorn could not do anything. AWI quoted $500 and on a 2nd try produced a usable pipe (within a few mm of the original) in stainless (and thicker than the Socata pipe on which some derisory comments were made re the very thin metal used) so that was installed

It’s been an interesting experience, especially discovering that of the firms advertising exhaust “repair” (which, given lack of STC or PMA is done by utilising some tiny portion of the old exhaust in the new one, so it is classed as a “repair”) none actually have a template derived from an original Socata exhaust. Of course the dimensions of an IO540 and where the exhaust ports come out is known, but you need two other key bits of data: the dimensions and position of the muffler (for which Socata probably charge about 10k, so there won’t be a lot of them kicking around) and this has to be done right so the main exhaust pipe comes out exactly right relative to the cowling hole

Some people expressed incredulity that an IO540 could generate enough EGT to soften the steel. Even an acetylene+propane blowlamp – the hottest thing you can easily get short of oxy-acetylene – struggles to do that. But AWI said they have seen this plenty of times, once the metal gets thin. And the Socata metal is thin when brand new

That’s not an easy result to achieve. Some kind of fixture would be required, pulled off the original. I don’t know how they do it for $500.

Looks really nice.

Yes. AWI even advertised that specific part, by the Socata P/N, on their website.

They have fixtures and if you have a fixture then you can make pipes like this all day for $500. I think the issue was that these fixtures are developed over time, as customers send in their old exhausts.

AWI originally wanted the entire exhaust so they could get it right, which makes sense, but that is still not enough information because you can build a “perfect” exhaust with the muffler in a wide range of positions. I would not send them the whole exhaust because if the parcel got lost then my plane would have been grounded potentially for ever.

It’s been an interesting exercise and should serve as a warning to others to acquire spare exhaust parts as and when they can. In particular, the Y sections are most likely to fail.

I had an exhaust manifold issue like the A36 one shown by quatrelle in my Bonanza. Mine was on the inside, so not able to see on pre-flight. I had complained to my AI for some time that I would hear popping or backfire sound when I would close the throttle on landing. One day, doing some takeoffs and landings, a fellow pilot told me, my engine sounded really bad. Other than the popping noise when I closed the throttle, I did not notice any other indications. So the next flight I went with another pilot friend to listen to me fly the pattern. We did a thorough preflight before the pattern flight, and he put his hand inside the manifold and said, you are not flying today. Putting my hand along the inside of the LH manifold, I could feel a large hole, probably more than 2 square inches. I don’t know how it had been missed, for probably two annuals. The manifold could have been repaired, but I bought a new one because I did not like the thin metal on the pipes. With the new manifold, no more popping or backfire noises when I close the throttle. Fortunately, there was no heat damage on the engine as I hadn’t flown much that year because of the COVID pandemic.