That (many precautions being operationally not possible for many people) is what I meant to say.

Again…

flying >200 hours a year

flying at least every two weeks, even in winter

using pre-heat in the winter

having a heated hangar

venting the oil filler neck after flight

changing oil at 30 hour intervals

are all very good things to do, but for most of us, they are impractical. I don’t do any of these things, just like most of you. But then don’t expect the engine to go to TBO without some “issues”. Just factor that in to your budget and enjoy the flying. (I am not referring to a premature full overhaul of the engine, which in most cases is total overkill, but at least some type of “maintenance” might become necessary with these post-WW2 engines).

I don’t think the exhaust would help much because all you are going to do is push air into the cylinder that happens to have the exhaust valve opened. There is no connection to the crankcase which is the source of humidity as it contains the oil.

That is what everybody thinks, but apparently what happens is that over time (hours) the whole engine fills with dry air. The piston rings leak quite well

Feeding a tube into the oil filler hole is a good one. On a Lyco, that leads direct into the crankcase, no problem. You just need to buy a dipstick, to get the threaded component and then drill a hole in that.

Sorry, but some of this sounds like “homeopathy” to my ears.

Of course I cannot prove it (just like nobody can prove that the above makes sense, but in my view:

- Changing oil every 30 hours is a waste of oil, and money.

- Opening the oil filler cap after every flight might have some theoretical effect but I still don’t do it

Obviously, no one of us here can really prove “anything”.

But you really ought to dig a bit deeper into forums like COPA and Beechtalk. Most of these people there will advocate for all of the above practices. And some of those people really do have some scientific background and real operational “evidence” of the beneficial effects of certain practices.

For example, chemicists have found out that engine oil loses its anti-corrosive qualities after about 25 hours of use. Obviously, a little caution is always advised as to where exactly these things come from and what interests these people might have. Again, the only thing we can do is to acknowledge what has evolved from opinion to become “accepted common knowledge” by now. Don’t you also believe that what Mike Busch teaches is “common knowledge”? Well, he said that “we don’t wear these engines out, we rust them out”.

I don’t see any reason to go via the exhaust when there are two better ways to access the crankshaft (oil dipstick and filler neck). In my case I would also be concerned about the turbocharger.

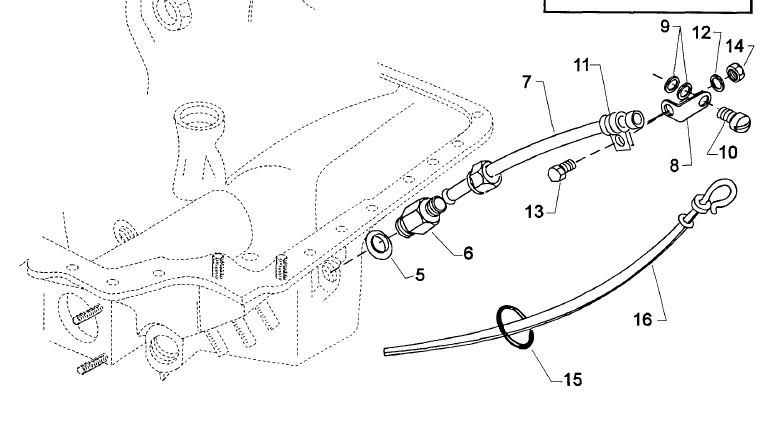

My dipstick is not of the screw-on type for whatever reason and I will just have a hose with a grommet to push it in. From the schematics, it seems the dipstick tube is just screwed on and does not extend into the crankcase. It also looks like the port where it is screwed on is well above the oil level.

Maybe a more advanced version would be to pour the silica gel cat litter into the engine through the oil filler neck. I’ll leave that to others to try out though

Yes, Bosco – i know that Mike Busch and other people at COPA (Jim Barker!) know a lot about these engines, and i try to follow their advice whenever i can.

But i also think while changing oil every 25 hours might have some small positive effect it is much less important than regular flight. Especially in the winter i try to fly at least once a week, although sometimes not even that is possible (due to long fog periods at my home base)

My main experience is with the O-320 in my Warrior, so not completely comparable. But these engines are ruined by ignorant pilots a lot too. I for one flew my old plane (Warrior) regularly, i never did long power of descents and didn’t “baby” the engines. I am convinced that babying engines with 2200 rpm kills them too …

I guess one needs a little luck too with these engines when factory tolerances are high and used materials differ so much.

Just my 5 cents …

Sure, rental aircraft are a little different, but I thought we were discussing mostly from the perspective as owner-operators.

Just one example: this one has flown 447 hours in the past twenty years! I would be very wary if I considered that airplane. OTOH, one could obviously argue that if that engine has not been majored in the last twenty years, and the aircraft has a valid ARC, then these long periods of disuse can’t be all that bad…again, there are often no clear (scientifically proven) patterns of what is “good” and “bad”…

Well, let’s put it this way… i guess we all can agree on this hitlist for the IO-550 (example)

1. Flying regularly

2. Flying regularly

3. Flying regukarly

4. Operation according to the latest proven experiences: LOP, no CHT avove 380 F, no shock cooling etc.

5. Maintenance aspects like oil changes (the more often the better)

Until I ruin my first set (;-)) I tend to think that most cases are really pilot induced.

Although bad operation can shorten the life of a cylinder, IMHO this is not the primary cause with Factory New TCM cylinders. TCM has changed their design over the years. Prior to 1992, IO520 TCM cylinders would for the most part last until TBO or beyond, still giving compression readings in the mid 70’s. There are at least two changes made since then. They changed the piston rings and the typical engine went from burning a quart of oil per 10 hours to a quart in 25 hours. They also changed the process for their valve guides and valve seats, probably to save money. They maintain poor tolerances, and the valve stem has too much movement. Look at the aircraft for sale and notice the number of aircraft that have a statement something like, “900 hours total time, 300 since complete top, new cylinders”. I know of some premium engine overhaulers who will purchase new cylinders from TCM and completely redo the valves, guides and seats before they install them on an engine. These cylinders will go the distance in most cases. When a client asks what I recommend, new or overhauled, I recommend first run overhaul by a competent shop and only use TCM new if they are selling the airplane. There is very little cost difference, but a great difference in quality.

I think running the engine at cruise powers LOP is better for the engine than ROP because the engine runs cooler and cleaner, but this rarely makes a difference in cylinder longevity. The biggest risk for a TCM engine is running too lean at full power as in takeoff power. This can cause engines to run well over 400 degrees and wear out the top end in short order. TCM SID97-3F details setting up the fuel flow in the TCM injected engine. I recommend that the maximum fuel flow be treated as a minimum fuel flow setting in a TCM engine. For example TCM recommends a fuel flow at full power for my IO-520BA to be set in the range of 23.2 to 24.9 GPH. I recommend an absolute minimum of 24.9 and prefer 26 to 27 GPH. I have seen customer airplanes that can barely reach 20 GPH.

Yes, for the IO-550N the value we trade across all Cirrus forums is 28 GPH. Below that with T.O. power the FF has to adjusted. Mine has 27.9 … I guess that’s fine.

I would challenge this “fly regularly” dogma. It sounds very nice and easy but there isn’t much proof behind it. Sounds like the doctor telling you to exercise regularly. With oil in good condition and low humidity, an engine can sit for a long time without taking harm. A frequently used aircraft can show massive engine corrosion, I’ve seen that happen.

I consider regular oil changes (25-30h) to be far more important. The 50h that is standard today is too much. It was less than 50h until the modern filters were introduced but that was a bad move.

Regarding FF. If you can maintain <400°F during takeoff, then your fuel flow is fine. The CHT is more important than the absolute GPH value.