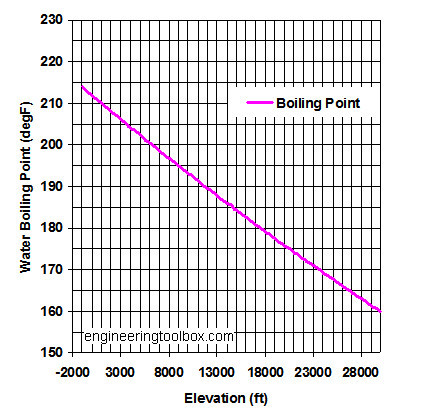

The boiling point of anything that boils is dependent on the ambient pressure

So somebody flying at sea level will need 212F to boil the water off really quickly, while somebody flying at 8000ft will get the same effect at 197F. To get it at 180F you will need 18000ft.

That’s to get instant vaporisation. Lower temperatures will still do it but progressively more slowly. But it will still be altitude dependent.

The crankcase is vented to ambient with a 2cm diameter pipe.

So IMHO 180F is “just a figure”.

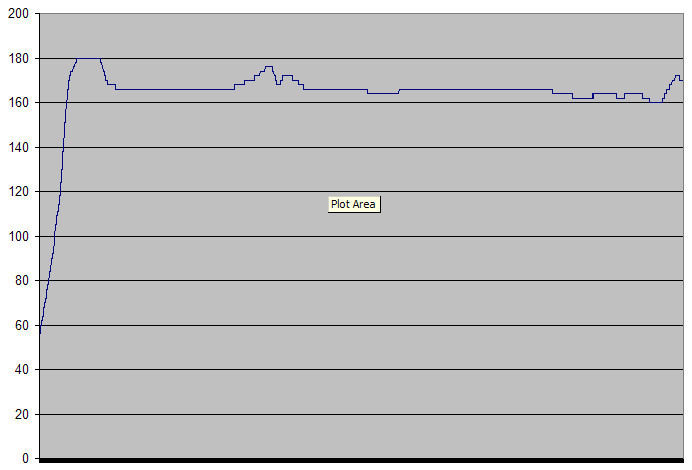

Mine reaches 180F during climb

Peter wrote:

I now see W80+ sold along W80. What is the difference supposed to be?

W80+ includes an anti-scuffing agent, equivalent to Lycoming LW-16702. That is required if you run Lycoming engines on AVGAS 91/96UL.

I also run 47.5% W80 and 47.5% 15W50 plus 5% Camguard. Seems to work well and it covers all the bases.

Peter

Perhaps "boiling off " was the wrong term, Lycoming recommend this number and about 40 min flying to be the time sufficient to get rid of the water in the oil by evaporating.

On some types of Lycoming the breather is overly long and I am sure that the moisture condenses in the breather an in some cases may run back into the engine.There is no restriction on the breather pipe insulation that is part of the Cessna winterisation kit being left installed when the temp is above that for the use of rest of the winterisation kit. I would recommend that the insulation is left in place year round to help the crankcase gasses breath to atmosphere without the chance to condense.

I thought this thread is of great relevant to this time of the year.

I have now stopped using 15W50. It’s pointless for much of Europe.

I would of thought a multi-grade would be very much significant for much of europe.

I would have thought that too, but clearly it is pointless, and has some downsides like damage to oil seals.

W80+ includes an anti-scuffing agent, equivalent to Lycoming LW-16702. That is required if you run Lycoming engines on AVGAS 91/96UL.

What does this actually do? Is there any benefit at all in W80+ if running on 100LL?

Peter wrote:

What does this actually do? Is there any benefit at all in W80+ if running on 100LL?

Makes you not have to add the Lycoming LW-16702 additive that is required on some oddball engines and suggested on a bunch more as detailed in Lycoming SB 446 (local copy of Lycoming SB 446E)

See the “Benefits” section of the Aircraft Spruce page for Shell W100PLUS for reference.

Edited to add references to Lycoming SB 471 for TIO-541-and TIGO-541 series engines (local copy of Lycoming SB 471B) and Lycoming SI 1409 about the use of the LW-16702 oil additive (local copy of Lycoming SI 1409C)

It sounds like W80+ / W100+ is worth using in any engine, even if Camguard is used.

So why not just put aeroshell 15W50 in?

Multigrade and comes with the Lycoming additive.