Does anybody know the exact current rules?

Let’s say the leading edge of a wing has been damaged, and also it damaged an internal rib. Let’s say that

The skin can be replaced using standard repair methods. Remove the skin, and make a new piece from aluminium.

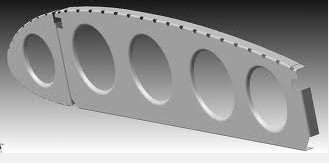

The rib, say it looks like this

can also obviously be fabricated, with appropriate skills and methods, but it’s a lot more work. Still, nothing new here since about WW1…

What is the required procedure to keep it legal?

For N-reg, AIUI, you need to show that you are using same or equivalent materials. For the skin and the rib, the material will be some standard material and the thickness can be measured off the existing parts. Then you need to copy the dimensions exactly. An A&P alone can do the repair, logging it IAW AC43-13. No need for a DER if nothing is changed.

For EASA-reg, there must be a procedure, but what is it?

It is a CofA plane, say a TB20…

The above is hypothetical (well, it was posted to find something out on behalf of a colleague  ) but it is in fact true that Socata will not supply any part of a vertical stabiliser. You have to buy the whole thing for €8k+VAT (2009 price) which is pricey but not out of line with other aircraft makers like Cessna or Piper.

) but it is in fact true that Socata will not supply any part of a vertical stabiliser. You have to buy the whole thing for €8k+VAT (2009 price) which is pricey but not out of line with other aircraft makers like Cessna or Piper.

The answer is the soon-to-be official CS-STAN: https://easa.europa.eu/document-library/notices-of-proposed-amendment/npa-2014-24

The relevant text:

Subject: Aircraft Repair according to FAA Advisory Circular AC 43.13-1B

1 – Purpose

This Standard Repair is issued to allow the use of FAA Advisory Circular AC 43.13-1B for repair of aircraft

structure in metal, composite and wood construction.

2 – Applicability/Eligibility

Aeroplanes not being complex motor-powered aircraft and any ELA 2 aircraft.

3 – Acceptable methods, techniques and practices

The following standards contain acceptable data:

— FAA Advisory Circular AC 43-13-1B.

4 – Limitations

N/A

5 – Manuals

Assess if the repair could require the issuance of an AFMS.

Amend the Instructions for Continuing Airworthiness to establish required maintenance actions/inspections

and intervals, as required.

6 – Release to service

This Standard Repair is not suitable for release to service by the Pilot-owner.

A beautiful bit of regulation!

Interesting, a friend was in this exact situation (wing leading edge damage) with another European manufactured light plane, on N-register. The manufacturer likewise refused to sanction the repair, and in fact said they would not sell any parts for the aircraft, forever, unless the owner bought a wing from them.

If the plane is on an EASA register the first thing might be to check if the maintenance manual contains regulated ‘guidelines’ for wing repair. In the case I mentioned these would forbid repair of the damage even though it was relatively simple. The same MM text was included in the FAA approved version but is illegal under U.S. regs – which the FAA was initially reluctant to admit because they’d made a mistake in their review and approval of the MM. In time the owner was able to repair the wing using AC 43.13, structural calcs and some material data as the basis. In this case the repair was more complicated than just making identical parts and installing them, so DER work was needed. When confronted with the approved FAA repair scheme, 337 etc after the repair was complete, the manufacturer relented on selling parts to maintain the plane.

Under FAR part 21.303, section 2, an owner or operator can make, or have made, a part and install it on his own aircraft. The wording doesn’t exclude any specific part, which means that any part could be manufactured.

This has been a brilliant thread – thank you all.

A beautiful bit of regulation!

Yes, amazing. It must be that treaty which has brought this. I bet very few people in the maintenance business know this!

which means that any part could be manufactured.

That’s the owner manufactured parts concession.

I think you are right, but you (the person fabricating the part, or supervising its fabrication if getting somebody else to make it) must still be able to show that the item you are making is identical to the original.

While that is easy with say a wing rib or some relatively non-structural bracket, it would be much harder to show with a landing gear leg made of forged aluminium (not least because you have no access to the original design data… let’s forget for now that the part may have never actually been “designed”, way back in 19xx  ) and virtually impossible to do with a piece of avionics that contains a processor running some software i.e. anything other than completely trivial.

) and virtually impossible to do with a piece of avionics that contains a processor running some software i.e. anything other than completely trivial.

It’s actually an interesting discussion whether one could use this concession for repairing autopilot servos, to solve the KFC225 “smoking servo” issue. I think the answer is NO but only because only an idiot would repair the servo without changing the incorrect components which enable the meltdowns to happen, and if you do that, the part is no longer identical to the original…

But there must still be a process for the said landing gear leg, otherwise every plane no longer supported by the manufacturer would be scrap as soon as that item breaks and no ex-breakers yard parts can be found. Probably a DER can do it.

For an owner produced part you don’t need the design data (for a landing gear leg), assuming the design isn’t being changed – which is a requirement for owner produced parts. You do need adequate manufacturing data. For something like a Stearman originally designed with government money that is no problem because the manufacturing drawings are both available and unbelievably good. For other planes that may or may not be the case, and the part may have to be reverse engineered – which is usually considered OK.

A slight tangent into factory production (i.e. not owner produced parts) may be of interest: there is a group manufacturing 1920’s era biplanes today, and obviously they have to figure out brakes etc using 2015 manufactured components. One of the interesting things about that situation is that the design basis to meet the certification standards of that time was very simple. An example is that if the plane had brakes, the landing gear structural calculation had to show the gear legs statically strong enough to withstand maximum braking with the plane on the main gear (tail up)… and that was about it. A one sentence requirement or at most a paragraph. A related point is that the brake master cylinder may have come from a car of that era, but have been included in the overall aircraft certification. If it was never given a part number by the airframe manufacturer (which it wasn’t) there is a big paperwork problem in PMA’ing a replacement now – simply because the PMA can’t properly specify the part being replaced!

CS-STAN looks great, but with it moving at EASA/EU pace, it looks like it won’t be in place for another 6-9 months yet. What about any repairs needed in the meantime on European registered aircraft that would happily fall under AC43-13 if the aircraft were on the N register?

NIL: Without seeing the actual damage, I would first and foremost consider a patch and/or doulber type repair. Seems this is fast becoming a lost art, but there is NO practical reason not to implement a repair.

Not sure about Socata, but, all of the big 3 GA makers give detailed information on patches, rib and stringer repairs and even main spars. Further, AC43.13 gives plenty of “data” for such repairs, more than enough to cover the regulatory needs for this.

That does indeed seem the exact sort of repair that should be conducted, but with an EASA registered aircraft and CS-STAN not in place just yet, what is the legality of doing such a repair?

Peter – with regards to gear leg certification, companies like LASAR managed to do it for the Mooney; see this product for instance