We use bulk potting machines that meter the components in the correct proportion. You throw 20kg into each side and press the button for a shot of stuff. We have many different static mixers for different products. Shame you can’t get the two pack sealant in the double syringe pack.

I did it today with Sikaflex 295

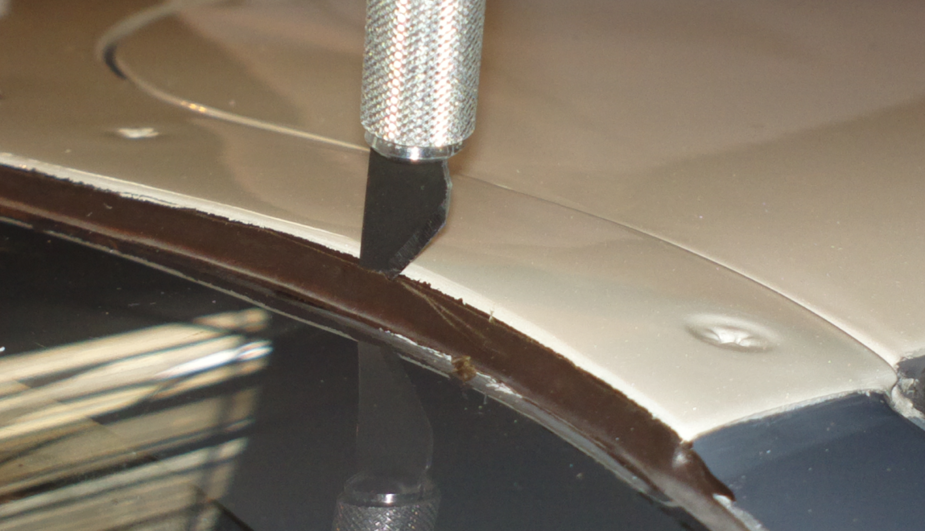

You have to cut along one edge

and along the other edge

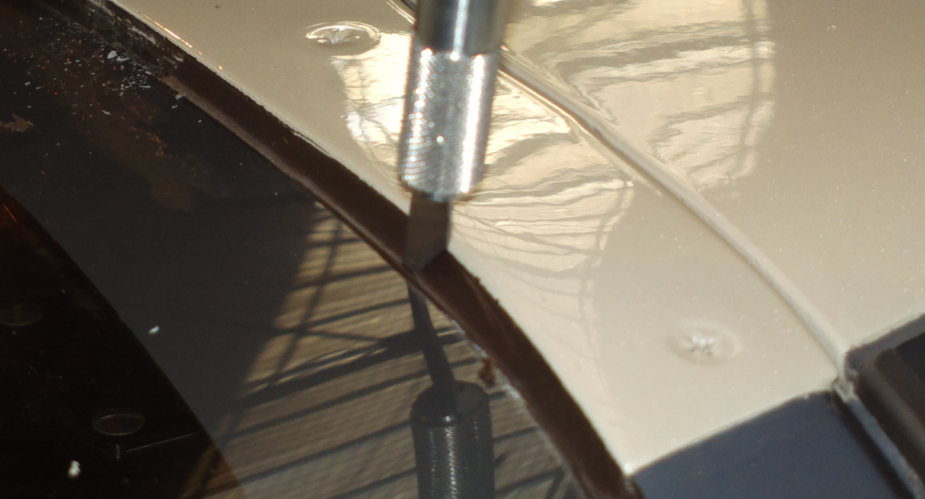

then dig out the bead of the old stuff

(removing as much as possible of it, especially off the edge of the transparency, to which the adhesion is most important because there is only the edge which one can seal to)

Use a decorator’s rubber thingy to make a nice radius

The result is pretty good

Cleaning off the excess here and there will have to wait till it’s dry, and it is sure to be “interesting” because this stuff sticks.

The old Socata seal became useless partly because the PR sealant they use was not flexible enough in tension (and cracked) and partly because while they did apply it under the windshield as well as along its edge, the windshield had a grey-painted pattern on the inside edge (visible in above pics) and trying to seal against that is a complete waste of time because the paint will just come off the plastic!

If anybody wants the remaining sealant (which will go wasted because there is no way to seal the end completely) drop me an email. I have about 80% left.

Nice job Peter. Usually I make a reasonable job of something like that, but not without making a mess first. Getting it right the first time takes some discipline.

Hi !

Struggling with the bottom seal of my 182 Windscreen.

It’s been redone two times, and in the end, the space between the windscreen and white « rain flap » being flexible, the seal loses its watertightness.

PR was used initially, and silicone last time.

It wouldn’t stay efficient for more than a year.

I wonder what is your experience, and how long it would last (@Peter ?)

3 years later, the Sikaflex 295UV job is still holding up fine

I think most “silicone” on the market is of poor quality – designed to seal the gap behind a bath…

So in your opinion, no need to go for the much more expensive PR stuff ?

PR1422 is no good for the flexible seals required for plastic windscreens, as they expand and shrink over temperature.

I use this for almost everything structural where I want a tight, seal. It also has rather good strength. I have even used it to glue curtain rods in my bathroom directly to the wall tiles  (6 years and still holding like a champ). Some have even used it to glue the canopy plexi glass on their RVs, instead of screwing it on. For pure sealant of acrylic, I guess this is better though, much cheaper at least, but haven’t tried it as of yet.

(6 years and still holding like a champ). Some have even used it to glue the canopy plexi glass on their RVs, instead of screwing it on. For pure sealant of acrylic, I guess this is better though, much cheaper at least, but haven’t tried it as of yet.

A problem with acrylic glass is that some sealants/glue etc will eventually crack it over time. It’s common to use loctite to secure the threads on screws, but that should never be done close to acrylic glass. Over time it will evaporate and crack it.