So how would you deal with it, thinking especially of a twin, but by all means in a SEP, and even with a two lever set up if you wish. However I am thinking of the implications of prop. feathering and different scenarios or power settings when the cable fails.

Fuji_Abound wrote:

So how would you deal with it, …

Feather the engine and cut the mixture, just like any other engine failure. If the cable fails in a “decent” power setting, say cruise or approach power, you can probably leave it running until shortly before touchdown. If it fails in takeoff power setting, you will probably need to shut it down earlier. But it all depends on many factors of course.

Doesn’t that depend on construction details? And even more on the type of prop (fixed, constant speed, …)

IF there is a spring on the carb(s) to pull wide-open-throttle if the cable parts out (as I think there really ought to be) then I cannot see much implications to the two still functional levers. You wish to set them according to engine regime anyway, don’t you? And the engine regime will be either maximum power or (after you cut the magneto’s) zero power.

On Lycos or Contis, none of the three controls are spring-loaded.

If the throttle cable breaks, you still have the mixture for reducing, or possibly to a small extent increasing, the power.

I preflight check the linkages at the engine end but on many airframes they are not visible.

It’s a good topic because a lot of people have rusted-up control cables which can break.

Peter wrote:

On Lycos or Contis, none of the three controls are spring-loaded.

In many installations (especially twins) there are two control cables running to each throttle, one for each direction of movement. So if you are lucky and notice early that the throttle will move only in one direction (if you are very lucky then it will still move in the “close” direction), you can leave it where it is and perform an normal landing with normal power reduction.

Other options would be to switch off one magneto or use carb heat for some reduction of power.

But I think a broken throttle cable is an extremely rare event. I have seen a lot of things happen to me and the pilots around me, but this is not (yet) among them.

If the throttle is full open, and your engine is capable of deep LOP operation, you should be able to reduce power by reducing RPM and leaning enough into LOP to obtain cruise power.

what_next wrote:

two control cables running to each throttle, one for each direction of movement

That’s clever! I’ve never seen it implemented, though – but then I’ve not looked under the hood of twins very much.

That’s not common on SEPs.

It’s done because a control cable is good in tension but obviously less good in compression. Also twins have much longer cable runs. On a typical SEP the cable is about 1m long.

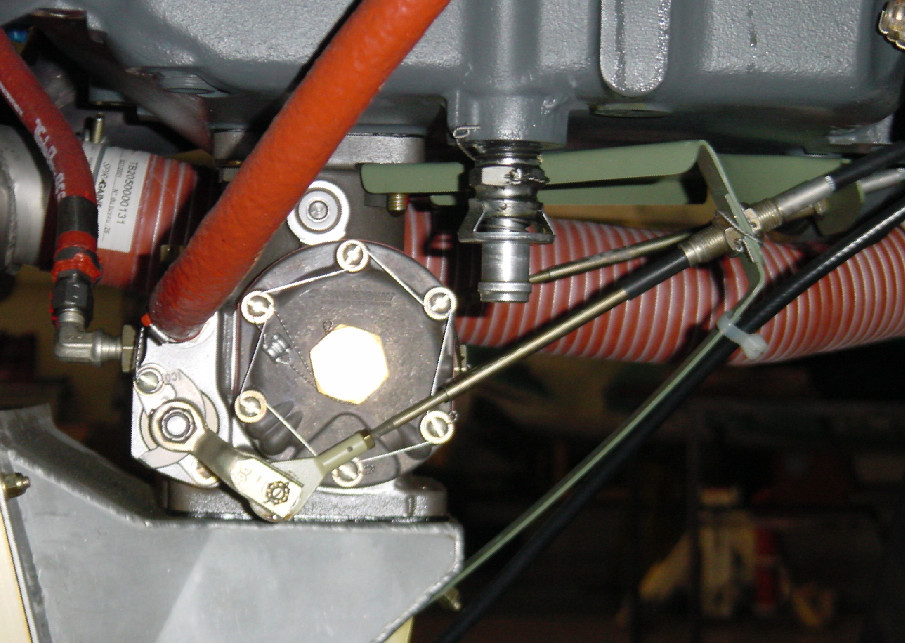

Also there are 2 kinds of “cable”. One is quite a thick and stiff one, which doesn’t take much of a bend radius. The one in the above pic is like that. I reckon the actual cable is about 3mm diameter. The other is about 1.5mm diameter, can be bent a lot more, and looks much closer to bicycle gear cables; that type can’t “push” really and you would need two of them.

Push-pull cables for engine controls like mixture or carb heat often have a solid inner wire and work well for aircraft because they’re light, the application doesn’t need a small bend radius and because return springs are considered bad practice in certified aircraft – return springs on linkages fail suddenly due to fatigue. Throttle cables are also push-pull as noted by others above but sometimes use larger diameter stranded cable – large enough that no return springs are necessary even though the cable is stranded. The flexibility of the stranded cable helps them operate smoothly and for more cycles (as required for a throttle control) but they weight more than solid wire control cables. Stranded push-pull throttle cables almost never fail, even after many decades of use.

The two cable push-pull throttle control solution was also introduced on Japanese motorcycles in the late 70s and is commonplace there. I think the intent with two opposing tension cables is that if the mechanism gets stuck, a lot of force can be applied to unstick it.

My father, working on military aircraft design in the 50s was told if he designed in a light aircraft style Bowden cable, he’d be fired! But they work fine when implemented well. Certified aircraft designers actually do and did think about this stuff quite a bit, and I think it’s an area where home builders and UL designers should concentrate more than they sometimes do.

A decent generic write up is here

Peter wrote:

On Lycos or Contis, none of the three controls are spring-loaded.

Not true. On my Lyco all three controls are spring-loaded.