Peter wrote:

I’ve never seen mags being cooled by airflow. This is my IO540, dual mag, no airflow on it at all

behind the firewall, also insulated from heat. The Bonanza has them on the upper side of the engine where cool air circulates.

I find that all a bit strange I must say…. they spend 100k on a problem like this…

The daily work keeps you from the actual fun, so we will continue to work on the plane the next weekend!

Because we did not focus on the magnetos at first – came with the new engine – I did not pay attention to the different RPM during the run-up.

We will keep you up to date!

The owner is a absolut professional in his field of study who, just like me, expects the same professional service from EASA certified maintenance shops. Unfortunately this is not to be expected.

Now we are in a fine mess and try to solve the problem, so thank you all for your help!

behind the firewall, also insulated from heat.

The magnetos will always be shielded from the air flowing through the cylinders by the rear engine baffle (not the firewall; that is further back) whose purpose is to make sure all the incoming air flows in between the cylinder fins, but the magnetos are firmly screwed to the crankcase which gets pretty warm.

But in this case the mags were changed, so how could the replacements be defective also? Are they the wrong ones, or done by the same overhauler who made some dramatic mistake and used the wrong parts inside, making them marginal over temperature?

And same question regarding the fuel servo.

All the time you are using the same parts from the same place, you may be unwittingly maintaining the same situation. I have seem many cases (aviation and elsewhere) where a defective part arrives, you send it back, and the replacement has the same defect. This can be because

Years ago I returned a KI229 RMI for an overhaul exchange and the replacement was one which I returned to them several years earlier. Both had the same fault, and neither worked, but the 2nd one was “absolutely 100.000% serviceable and perfect”

Humans are ingenious creatures, even more clever than monkeys, but that also means they find more ways to screw up

Initially, shop A, B and even C just poked around. Therefore, the decision to buy a brand new engine directly from Lycoming and thus also new magnetos, ignition harness and fuel pump. Why the fuel injector was defective can not be answered in retrospect. This one is also repaired meanwhile.

The old engine was later returned to Williamsport.

Only we had to learn that the governor is not included in the package. This has now, as mentioned, been overhauled.

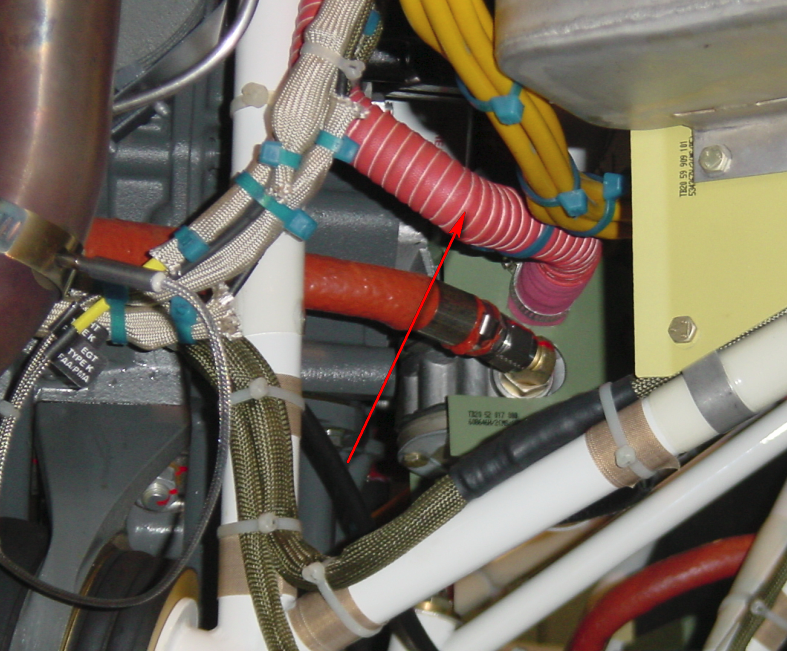

Through the many suggestions in the last few days, we came up with the idea of cooling the magnetos.

Interestingly, most Robin models have a cooling system for the magnetos, some even one for the fuel pump and the oil filter.

Only the DR500 does not have it at all.

Another special feature of this plane is the three-blade propeller.

Maybe that’s why the flow conditions of the cooling air are not optimal.

We will give it a try…

I am far from being an expert on this and I paid 3000€ on work this year to finally confirm that oil pressure fluctuations on a Rotax 912 are factory normal – you just normally don’t see them, depending on sensor and instrument technology. So I am not in a position to teach you.

But: from what I read, your approach appears to be haphazardly to me. No clear-cut question, no definition of hypothesis, no definition of variables, no interpretation of results. Thus no gain of knowledge. I would just suggest to avoid the phrase “let’s try …” in the future.

Fuel flow meter can be borrowed easily, and so on.

Concerning the problem at hand: you can easily check the temperature at the installation area of the magnetos (instruments come for 1€ something from China). Before I drill random holes in your airframe, I verify the temperature. No need for action if the temp is in the 30°s or 40°s.

It is common to have an air hose to cool the engine driven fuel pump

but not the other stuff.

Also in my 18 years of flying I have never heard of mags getting too hot. I can’t say this never happens but these engines, 1950s/1960s designs, just keep working, all over the world, in hundreds of thousands of planes, everywhere from Alaska to equitorial Africa, from -50C to +50C ambient (even I have flown in -37C for an hour or more), so there is something deeply wrong with looking for temperature dependence in magnetos etc.

I reckon there is a faulty item somewhere which has not actually been changed, or somebody is milking the owner. How common is a Robin in Germany and how much did thos one cost?

mags do have a temperature problem in so far as a defect in the ht windings OR the capacitor FIRST shows at higher temperature at above say 60 degrees C . I did reproducable tests in my oven with suspect mags that caused misfiring after half an hour in the air . Many guys who had a moped or motorbike in younger years could tell stories that the engine was fine for half an hour and then died, magneto or ignition coil and capacitor within the engine case mostly. Give it half an hour to cool down and the sparks returned. Same with my oven tests, mags were OK cold , big spark of 12mm when spun by fingers, two hours in the oven at ca. 70 degrees and then only half of that, in my case the capacitor is between primary and ht winding within the coil – idiocy. In flight the mags get near 60 degrees behind the radial cylinders, no baffles there. The helicopter version had direct air ducts to the mags for a reason. When coils and capacitors are defitely OK and recent production, 100 degrees should not matter, not so, when aged or defective. Am I right that mags are sent to maintenance in 500 hours intervals ??? Defective coils are not unheared at all.

With all of this in mind I specifically asked for info if that Lyco was mag tested with hot engine to exclude the mags while fault finding – never trust anything without testing, even new parts. Had two coils recently factory new, old stock possibly, from Kasachstan: One OK after a 5 hours run in the oven at 70 degrees , see picture, the second not so great !

Vic

Robins are frequently used in flight clubs for towing gliders, but more the 400, not the 500.

That’s an impressive test, Vic

However my original point stands, about how many magnetos are working ok around the world, in extremes of temperature. With brand new parts, there has to be something weird going on here.

According to wiki, this type is extremely rare: 18 were produced in 1999 and 9 in 2000.

the mags could be ok when cold but getting too much heat when operating. Baffling system is what I think. Not enough/ inefficient airflow when running; mags, fuel or intake system malfunction as a secondary effect due to the heat.